Metal Stitching Salvages Badly Damaged HP And LP Compressor Casings

A machinery repair specialist contacted Goltens with an urgent request for repair support on badly damaged compressor casings.

Learn More Download Now

A machinery repair specialist contacted Goltens with an urgent request for repair support on badly damaged compressor casings.

Learn More Download Now

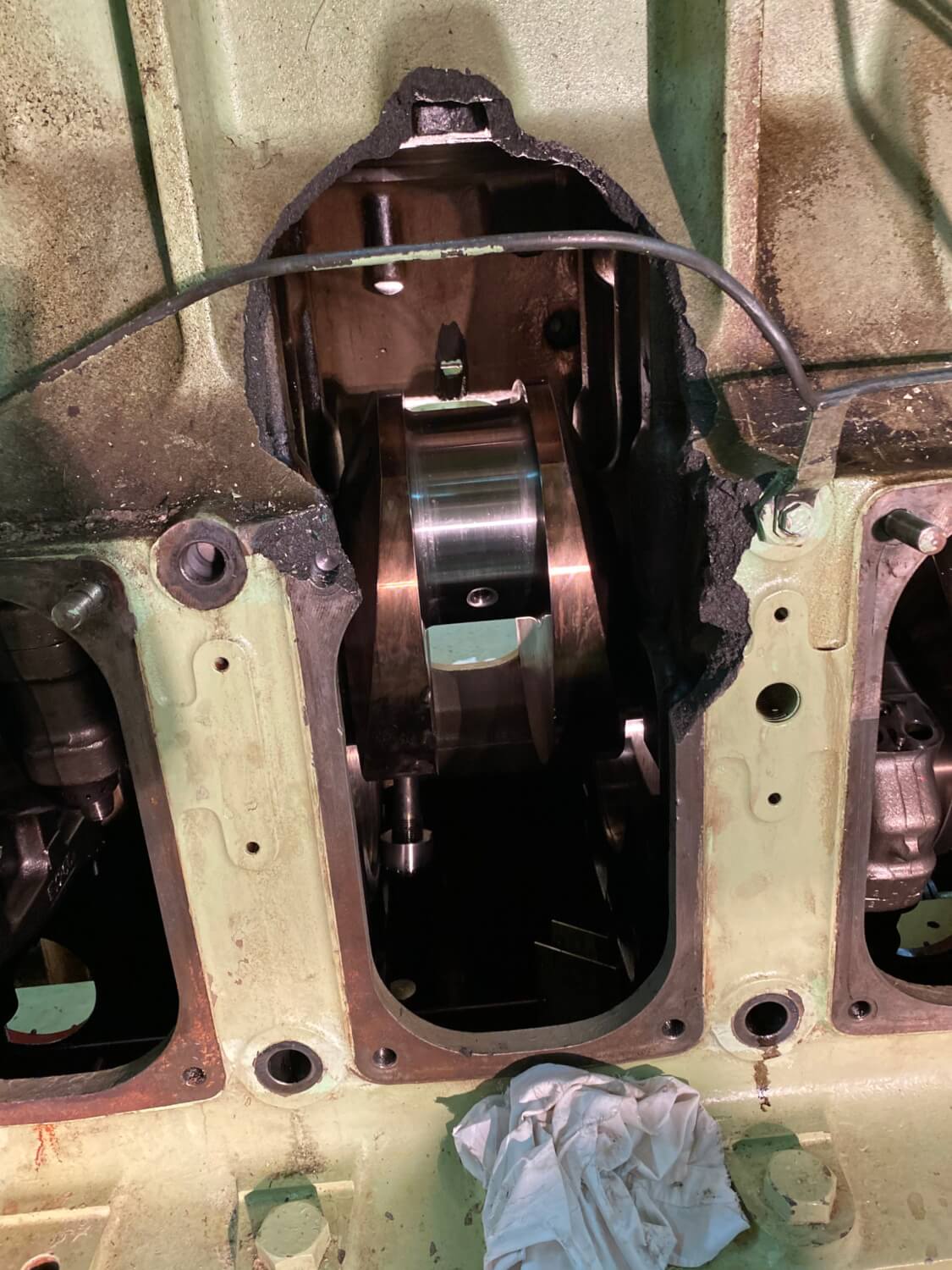

Goltens was engaged to inspect the main-engine crankshaft on a 23-year-old, 11,700-dwt chemical/product tanker anticipating that the crankshaft could be salvaged with in- situ machining.

Learn More Download Now

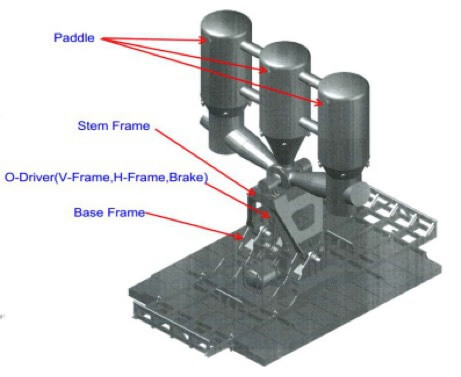

A Chinese PTA chemical plant, with 1.5 million tons of annual production, was undergoing an emergency overhaul on a large multi-axis air compressor critical to plant production. Due to the criticality of the compressor, the plant was pressing for the shortest possible completion.

Learn More Download Now

A polyester plant in Indonesia was planning a shutdown in four weeks and suspected that the polyester reactor’s 285mm diameter agitator shaft was damaged and would require repair during the maintenance window. The maintenance window was short, and the extent of the repairs required was unknown.

Learn More Download Now

During periodic maintenance, the crew of a 14-year-old, 122,000 DWT container vessel, noted excessive wear and ovality on five of the six crankpins (#2 through #6) on one of their Wartsila W6L32 auxiliary generators. Crankpin #1 had previously been machined to undersize and did not require repair. The vessel owner contacted Goltens about undertaking the further inspection and rectification of the worn crankpins.

Learn More Download Now

Goltens received an urgent call from a power plant in the city of Gorontalo in Sulawesi. The plant’s 10MW Shandong Jinan steam turbine suffered a bearing failure resulting in a damaged rotor shaft. The power plant is a vital source of power to the city and minimizing downtime was critical.

Learn More Download Now

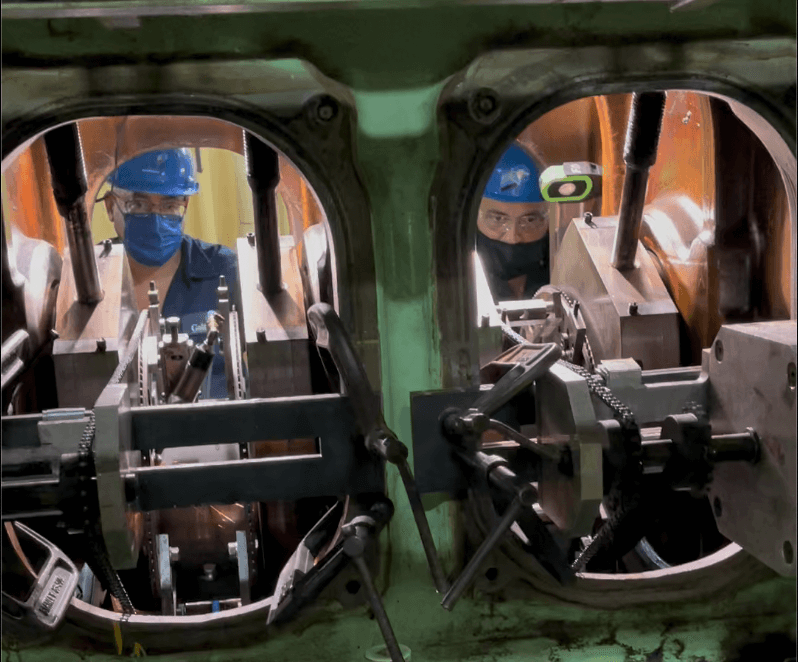

An 11-year-old container vessel suffered a major casualty on one of its Yanmar 6EY26L auxiliary engines resulting in pieces of the connecting rod breaking through the crankcase wall causing extensive damage. Knowing how operationally disruptive and exceedingly expensive a block replacement would be, the owner contacted Goltens Dubai to inspect the damage and determine if the block could be salvaged.

Learn More Download Now

Goltens was contacted by a containership operator to inspect damage on its MAN 9L 48/60 main engine crankshaft. During operation, the main engine’s connecting rod bolts gave away and caused major damage to crankpin number 4. Goltens boarded the vessel at Dubai Maritime City for inspection.

Learn More Download Now

A 12-year-old container ship was undergoing dry docking in China when issues with the main engine shafting were discovered. The coupling bolts for the flywheel and the intermediate shaft had elongated and been worn to an oval shape and there was 0.5mm clearance between the flywheel and intermediate shaft landing surfaces.

Learn More Download Now

A mining operation suffered a major bearing seizure on the crankpin of a slurry pump shaft. The pump makers approached Goltens to explore the possibility to repair and restore the crankshaft to original diameter in our workshop.

Learn More Download Now

A recently built general cargo vessel experienced a bearing failure on its intermediate propeller shaft bearing. Goltens was contacted to perform an inspection on the bearing shell and pedestal and to propose a solution. Upon inspection it was determined that the entire housing would require repair, due to extensive damage on the bearings, sealing areas, and housing mating surfaces.

Learn More Download Now

INSPECTION AND WORK SCOPE Goltens determined that the shaft seal liner could be removed from the shaft but due to the short space between the shaft and shaft housing, special tooling and brackets would have to be fabricated at Goltens …

Learn More Download Now

Once the gearbox was moved to a safe work area and the gears were secured, Goltens machined the damaged areas on the gear to ready the surface for repair. Technicians then applied selective electroplating to the damaged gear teeth using …

Learn More Download Now

PRE-MACHINING Goltens fabricated custom machining rings for installation and machining of the rudder stock. In-Situ specialists mounted carried out an initial removal of 10.00 mm off the diameter to create a reference point for the machining of the running surface. …

Learn More Download Now

After preliminary meetings and discussions on the tolerances of the bush and tube Goltens proposed a combination of on-site and workshop efforts to complete the work. ON-SITE WORKSCOPE Port and Stbd. Bore alignment laser checks In-situ line boring of Port …

Learn More Download Now

THE INSPECTION Goltens got the call on Sunday and engineers were on site the next day to evaluate the condition of the shaft and identify a repair method for the damage on the EDBG. Goltens undertook an inspection of main …

Learn More Download Now

WARTSILA 18V32LN ENGINE BLOCK REPAIR Goltens performed laser scanning on the damaged areas to facilitate the casting of precise inserts for the block. Goltens cropped the damaged interior and exterior sections of the engine to ensure clean mating surfaces and …

Learn More Download Now

THE RESULT The entire repair was completed inside of 5 days onsite inclusive of waiting and staging. Both sets of slip rings were machined to a surface finish of 1.0Ra in accordance with the manufacturer’s specifications and the turbine generator …

Learn More Download Now

PROJECT FACTS Description: MAN B&W HUYNDAI 7L23/30H Location: Portugal – US (under voyage)

Learn More Download Now

TURBINE ROTOR SHAFT REPAIR SCOPE Complete inspection of the rotor shaft including hardness checks, MPI, measurement etc Machining of journal radius/fillets Machining of the shaft journal to undersize 1.00mm Honing and polishing of rotor shaft journal Fabrication of bluing dummy …

Learn More Download Now

Read about how Goltens executed a detailed solution using its traditional in-place machining coupled with a low surface temperature laser cladding technology. To prove out the viability of the proposed repair, the repair process was tested on a scrap valve in …

Learn More Download Now

IN-PLACE MACHINING AND ANNEALING After the tender was awarded, Goltens in-place machinists first machined the crankpin to -4.5mm to remove all surface cracks leaving a hard spot 250mm x 120mm. Goltens then performed the annealing process and reduced the crankshaft …

Learn More Download Now

THE INSPECTION AND THE PROPOSAL During the inspection, Goltens learned that the engine had suffered the same casualty on the same cylinders 30 years earlier. The block had significant damage to the crankcase near the doors, liner landings and the …

Learn More Download Now

INSPECTION AND REPAIR PLANNING Goltens diesel experts were asked to inspect the damage and determined that the crankshaft could be salvaged within the rated diameter with in-situ machining and annealing. Crankpin journal number 7 (450mm diameter) and main journals number …

Learn More Download Now

THE BIOWAVE™: The bioWAVE™ ( http://www.biopowersystems.com/ ) is being developed for utility-scale power production from ocean waves. Its nature-inspired design (biomimicry) combines high conversion efficiency with the ability to avoid excessive wave forces, enabling supply of grid-connected electricity at a …

Learn More Download Now