METAL STITCHING SALVAGES BADLY DAMAGED HP AND LP COMPRESSOR CASINGS

OVER 6 METERS OF DAMAGE REPAIRED IN ONLY 11 DAYS WORKING AROUND THE CLOCK

A machinery repair specialist contacted Goltens with an urgent request for repair support on badly damaged compressor casings.

When large cast components develop cracks, oftentimes the only viable repair option is to metal stitch the cracks. Traditional welding methods are not effective for repairing cast iron and other cast metals and, in many cases, can result in more damage to the piece being welded.

THE INSPECTION AND SCOPE

Goltens deployed a specialist team to inspect the damage and propose a repair protocol to complete the repair as soon as possible. The inspection report from the customer had indicated extensive cracks and Goltens found over 5 meters of cracks during the preliminary inspection. Once the pieces were fully sandblasted, an additional meter of cracks were discovered around the casings for a total of over 6 meters of damage.

The customer indicated a need to have the casings repaired in 14 days. Goltens immediately mobilized the tooling and sent 3 specialist teams and project manager to work the day shift to begin the extensive works and then added two additional teams of specialists to be able to work around the clock to meet the aggressive schedule.

FOUR DAYS AHEAD OF SCHEDULE

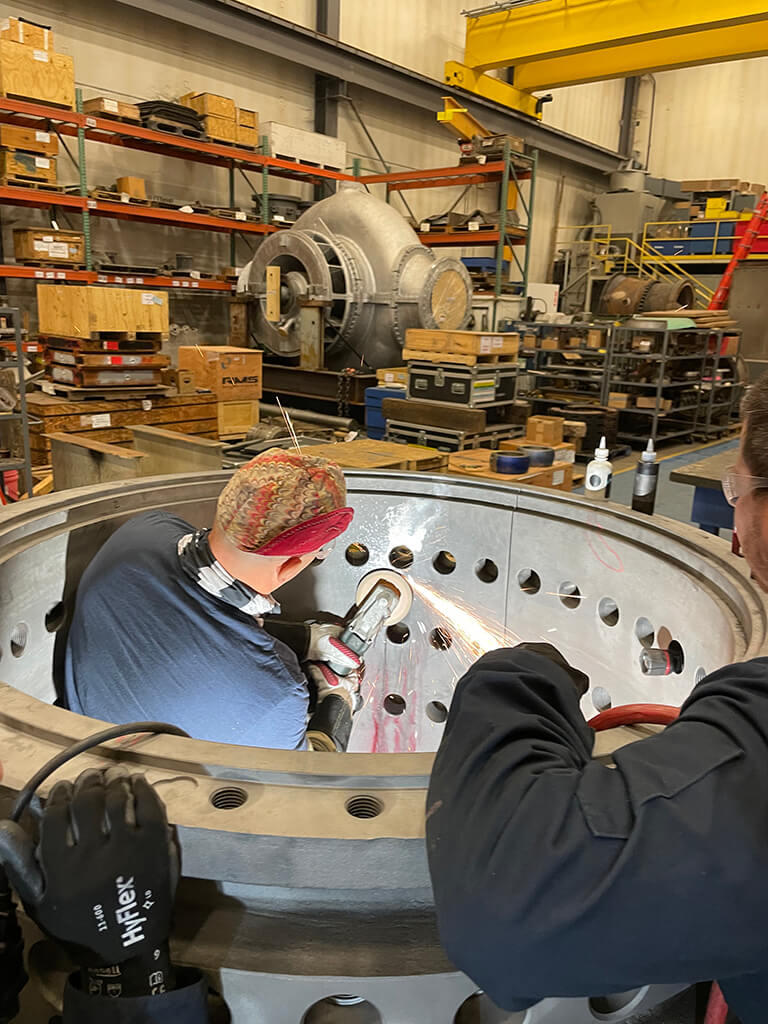

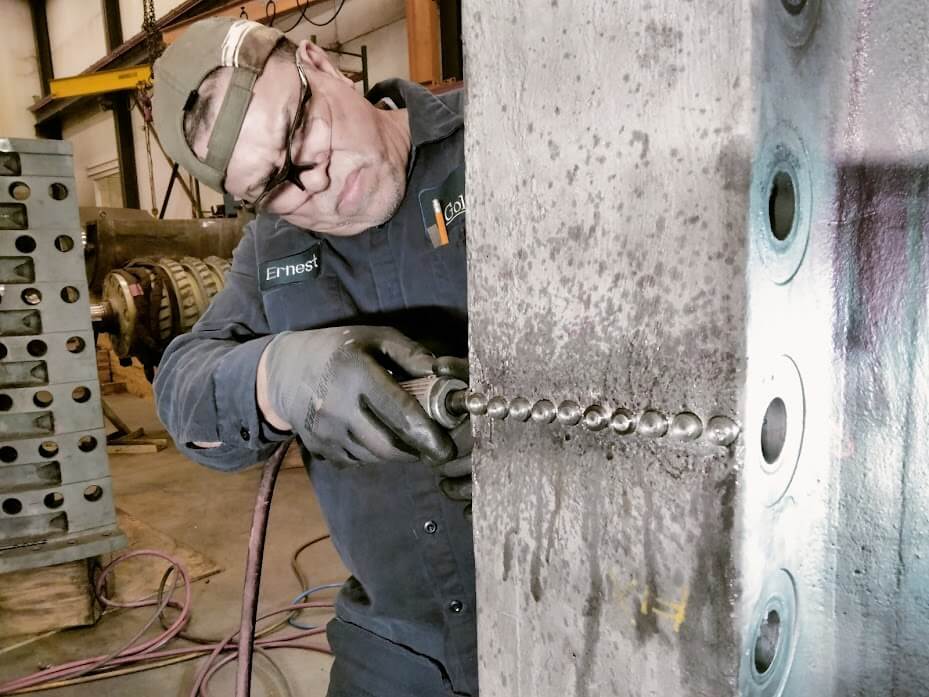

The five teams worked around the clock to complete a phased approach addressing the more badly damaged HP casing first. Each crack was drilled and tapped for the stitching pins to be inserted along the length of the cracks prior to being machined clean. Subsequently, using a drilling template, a precision hole pattern matching the dimensions of the metal locks were made at various points along the stitched seam to enable the insertion of the lock inserts perpendicular to the cracks. Once completed, the lock surfaces were also machined clean and crack tested before moving on to the next set of cracks.

The overall job was completed in only 11 days with the team of machinists utilizing over 1,200 stitching pins and over 60 locks to finish the repairs on the 6.1 meters of cracks.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now