In-Place Metal Stitching Salvages Another Badly Damaged Engine Block

GOLTENS METAL STITCHES YANMAR 6EY26L BLOCK FOR MAJOR CONTAINERSHIP OWNER

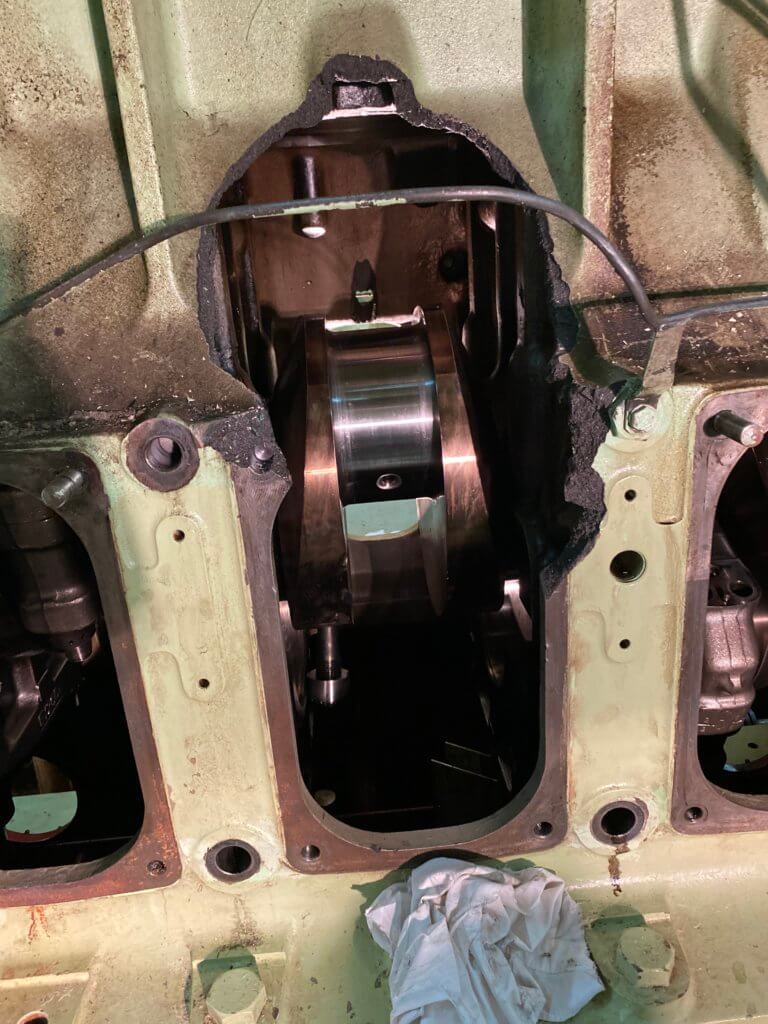

An 11-year-old container vessel suffered a major casualty on one of its Yanmar 6EY26L auxiliary engines resulting in pieces of the connecting rod breaking through the crankcase wall causing extensive damage. Knowing how operationally disruptive and exceedingly expensive a block replacement would be, the owner contacted Goltens Dubai to inspect the damage and determine if the block could be salvaged.

INSPECTION AND REPAIR PLAN:

Inspection revealed that the connecting rod bolts on one of the cylinders were loose and gave way and that the resulting hole above the inspection door was substantial in size. Additionally, the pieces of the block that were broken away from the engine were not substantial enough to be stitched together. In addition to the damaged inspection door, the lower liner landing surface was also damaged.

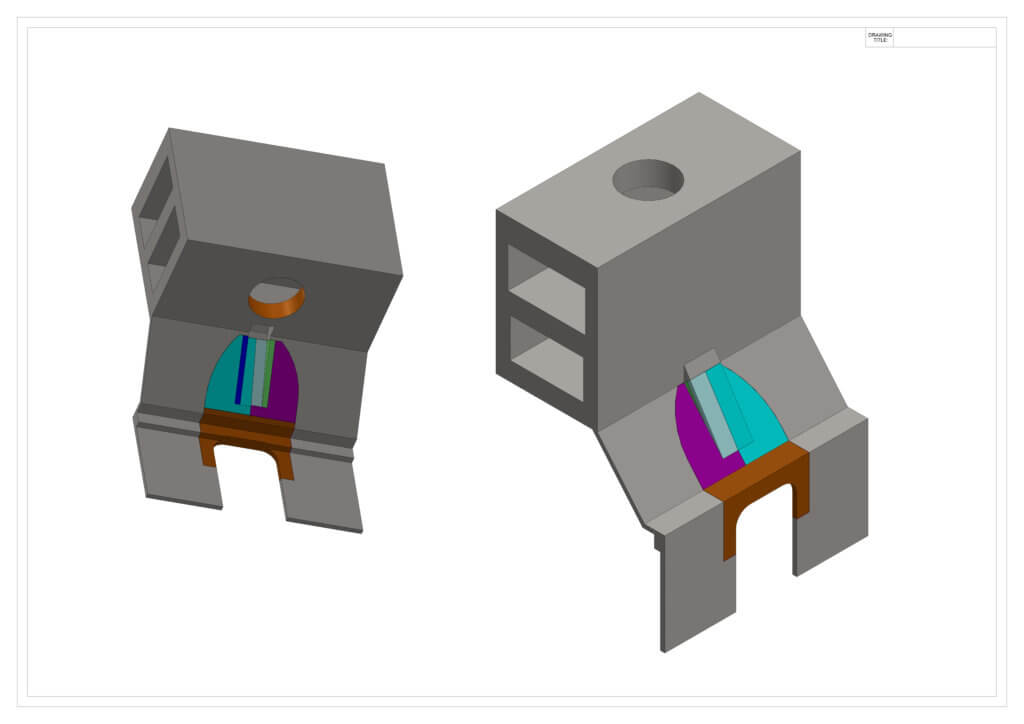

Goltens removed obstructions for clear access to the damaged area and carefully measured the affected sections to determine a repair protocol. For the lower liner landing surface, line boring that area and inserting an oversized sleeve was proposed. For the inspection door damage, Goltens proposed the fabrication of a cast insert that could be metal stitched into the block for a permanent repair. Goltens created a 3D model of the complicated insert and mobilized tools and technicians to complete the repairs.

BLOCK PREPARATION AND INSERT FABRICATION:

Goltens’ specialists cropped out a clean area to match the shape and dimensions of the modeled insert. The new multi- dimensional insert was fabricated to match the 3-D model that was created.

METAL STITICHING:

The fabricated insert was positioned and held in place with temporary stiffeners. Using a jig, the holes for the stitching pins were drilled and tapped and stitching pins installed to draw the sides of the cracked surfaces together. To reinforce the repair to the surface’s original strength, locks are then inserted drilling and tapping with precision jigs such that the locks are inserted into place perpendicular to the cracks.

FINAL STEPS IN THE REPAIR:

To restore the surface to its original condition and normalize the characteristics of the repair, the stitched surface was peened and ground level to the adjacent block surface. Once completed, die penetrant testing was completed across the entire surface to ensure no cracks remain and the repair is complete.

As a final step, holes for the crankcase door were tapped with a magnetic drilling machine and the repaired surface painted. The engine was then put through satisfactory operational trials at full load.

Another costly and time-consuming block replacement was avoided with Goltens’ metal stitching repairs. As always, minimizing asset downtime for our customers.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now