5 Day Turnaround On Yanmar Metal Stitching & Crankshaft Grinding

Connecting Rod Failure On Bulk Carrier’s Yanmar 6N18-UN Auxiliary

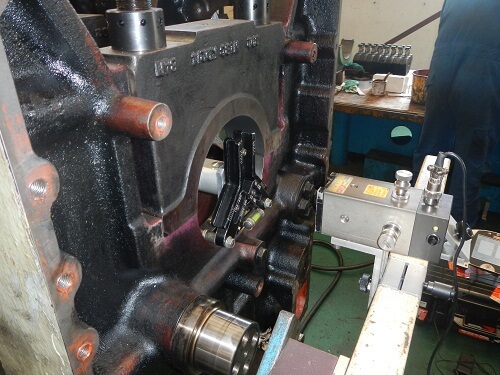

A bulk carrier’s Yanmar 6N18-UN auxiliary engine suffered a broken connecting rod resulting in serious damage to the engine block and crankshaft. During the vessel’s 5 year dry-docking in China for special inspection, the superintendent approached Goltens Shanghai to complete the repair.

Being Yanmar authorized and experienced in this type of repair, Goltens provided a repair procedure, approved by Class, to repair the block by metal stitching as well as complete the rest of the required repairs on the engine.

Goltens immediately mobilized two teams to repair the engine block and complete the crankshaft grinding working on a 2-shift basis in order to meet the vessel’s schedule.

Goltens also invited the technical advisor and Class surveyor to observe and approve the repair process.

PROJECT FACTS

| MV VTC OCEAN | |

|---|---|

| Engine Type: | Yanmar 6N18-UN |

| Output: | 450 KW |

| Vessel Type: | Bulk Carrier |

YANMAR DIESEL REPAIR WORK SCOPE

- Complete cleaning and inspection of engine block

- Complete cleaning and inspection of crankshaft at workshop

- Repaired the badly damaged crankcase door by metal stitching at Goltens’ workshop

- Performed laser alignment checks and line boring of main bearing pockets at Goltens’ workshop

- Performed straightening of the crankshaft and bench grinding on all crankpin journals to undersize 0.40mm and supplied 7 sets of undersize bearings.

- Polished all main journals

- Replaced 2 pcs damaged counter weights and bolts.

- Performed dynamic balancing test on crankshaft

- Safety protection of engine block and crankshaft for transportation back to the vessel.

ENGINE REPAIR RESULTS

Goltens technicians completed the full scope of the job in just 5 days to keep up with customer’s sailing schedule. Class approved the repair and the owners were satisfied with the timely performance of Goltens’ service team.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now