In-place Machining Minimizes Cost and Downtime for Tanker Engine Repair

TWO GOLTENS STATIONS TEAM UP TO COMPLETE THE REPAIR AND RESTORE THE ENGINE TO SERVICE

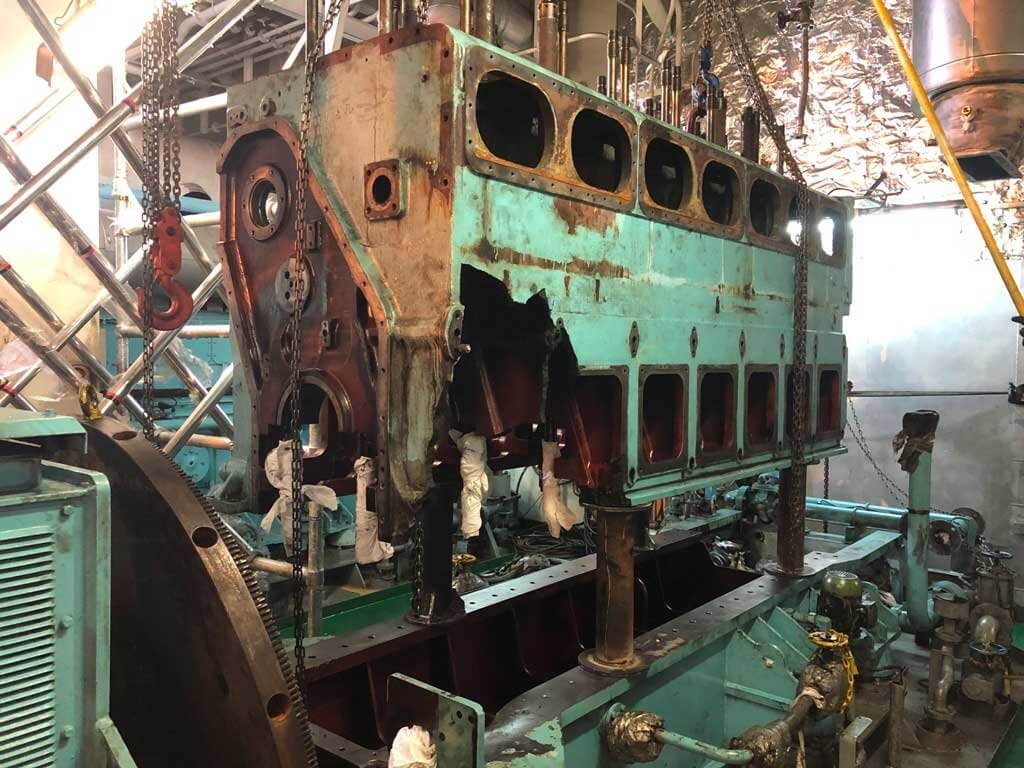

Goltens Dubai, received an emergency call to mobilize to Portugal to evaluate a major casualty on an MAN B&W Hyundai 7L23/30H on an oil tanker. The team evaluated the damaged engine and determined that the engine block and crankshaft were beyond repair and required replacement. Further, the bedplate had suffered major impact damage from the broken connecting rod and piston and its salvage was questionable.

Goltens dismantled the engine and rigged the condemned block and crankshaft from the engine room to the upper deck while the vessel was on voyage. They also rigged the damaged alternator which needed to be sent ashore for repair.

Despite heavy damage to the bedplate, Goltens advised that it could be salvaged with an in-situ repair while the vessel was sailing, minimizing the costs to the owner, the degree of disruption and the downtime of the generator. Goltens Miami’s in-place machining team came on board at the Louisiana anchorage in the USA to carry out the repair work of the bedplate while the vessel continued sailing.

To effect the repair, Goltens’ In-situ machinists milled the damaged area to 20mm depth and inserted a 22mm thick plate which was fastened to the bedplate with CSK headed screws. The excess material was milled to match the original surface of the bedplate. The repair process and all materials were approved by DNV class surveyor prior to undertaking the repair as well as the completed repair.

Post machining, the new block and crankshaft were installed, the block and bedplate foundation bolt holes were re-drilled and threaded and the alignment and flatness were rechecked and found to be acceptable.

All salvable engine components were overhauled onboard and Goltens Dubai’s riding squad completed the rebuild with new pistons, connecting rods and other components that could be reused. Goltens completed the engine alignment and full load tests prior to turning the generator back over to ship’s crew.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download PDF