Annealing And Machining Salvages Another Badly Damaged Crankshaft

MAN B&W 9L 48/60 CRANKSHAFT REPAIR FOR 600-TEU CONTAINERSHIP IN DUBAI

Goltens was contacted by a containership operator to inspect damage on its MAN 9L 48/60 main engine crankshaft. During operation, the main engine’s connecting rod bolts gave away and caused major damage to crankpin number 4. Goltens boarded the vessel at Dubai Maritime City for inspection.

INSPECTION

Initial inspection revealed that there were abnormal parameters observed on damaged crankpin. The bearing seizure resulted in deep scoring and the pin measurement showed a 0.65mm ovality. Additionally, the failure had induced extremely high hardness of 640HB across a wide area at the bottom of the crankpin, surface cracks, slight damage to the fillet radii and a heat induced bend of 0.25mm on both adjacent main journals.

REPAIR RECOMMENDATION

While high hardness can sometimes be removed by machining the journal below the hardness, this results in the removal of unnecessary material from the pin diameter with no guarantee of success. In order to salvage crankshaft at the minimum undersize, Goltens recommended applying its Class approved crankshaft annealing process to reduce the hardness.

ANNEALING PROCESS

Goltens pre-machined the journal surface to remove the surface cracks on the journal and set the target undersize at (5mm). The engine was prepared according to Goltens’ process and heat treatment tiles were then installed, and the pin properly insulated for the annealing of the crankpin.

The annealing was conducted in a carefully controlled manner where the rate of temperature rise, soak temperature and time, and rate of cooling are all preprogrammed into the system. Axial movement and expansion of the crankshaft were all carefully monitored during the heat treatment.

Once the crankpin had cooled and the tiles removed, the scaling resulting from the annealing was removed from the treated journal.

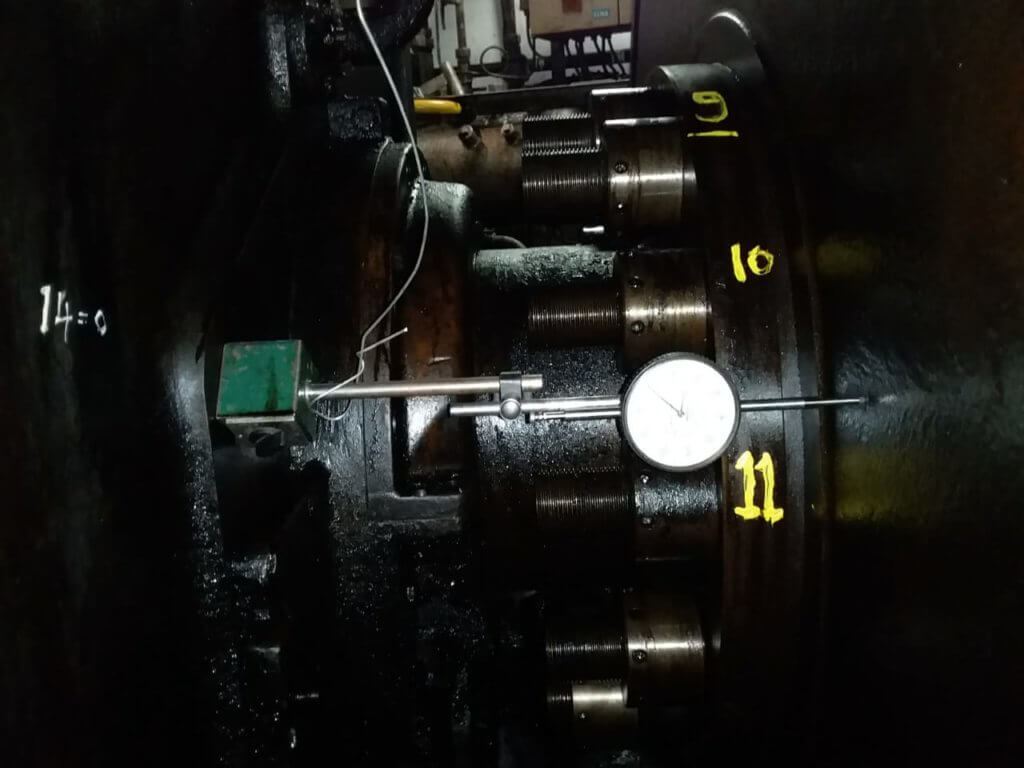

INSPECTION AND FINISH MACHINING

The hardness in surface had been successfully reduced from 650HB to an allowable measurement of 315HB. Peening was carried out to remove the small residual bend in the shaft.

The journal was then machined to final undersize of (5mm). Honing and polishing were completed to get to an acceptable surface finish and surface contact verified with a bluing dummy.

Goltens’ team overcame the logistical and safety challenges presented by the COVID-19 pandemic and completed the entire repair, inclusive of dismantling, machining, heat treatment and final assembly in short duration.

The customer appreciated the quality of Goltens’ team and Goltens’ approach to limiting the downtime on the engine and the expense of the repair.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now