Engine Block Repair - Metal Stitching Wartsila 18V32LN

CEMENT PLANT – DOMINICAN REPUBLIC

When reciprocating engine parts seize or break free at high speed, the results are never positive. If luck is on your side, emergency shutdown procedures can sometimes limit the damage, but when parts come loose from the engine the result is most often catastrophic.

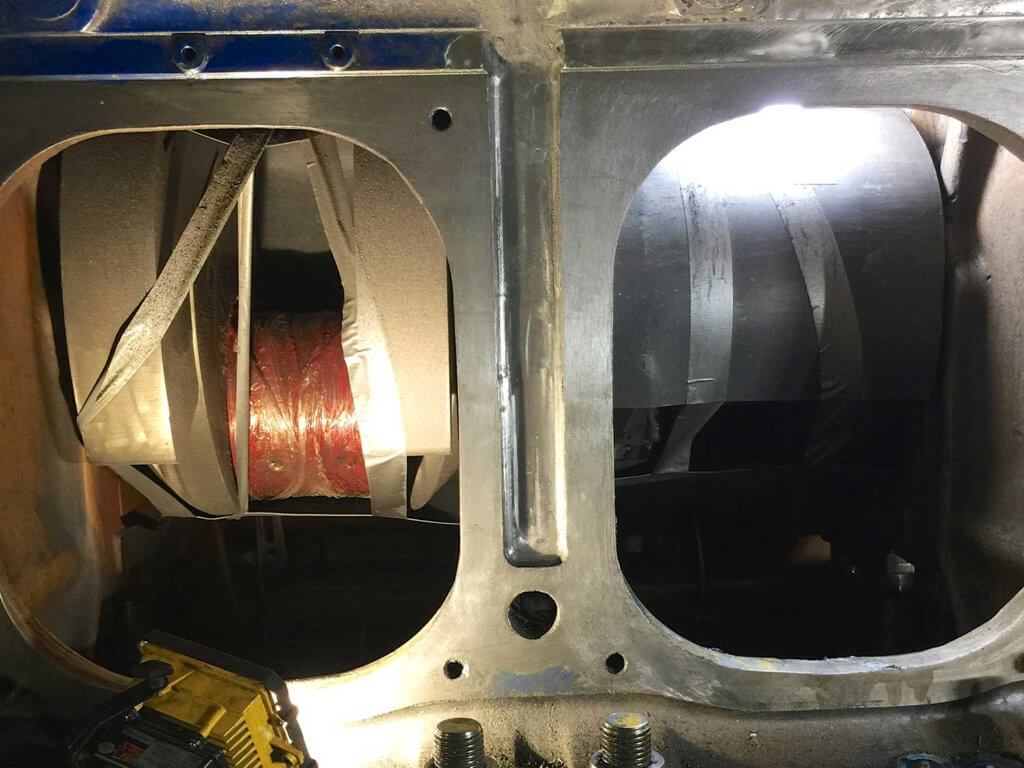

Such was the case for a leading cement producer in the Dominican Republic. During routine operation, one of its Wartsila 18V32LN engines suffered a connecting rod failure resulting in major damage to the engine block and the crankshaft. Collisions with the connecting rod knocked large pieces of the block free between the inspection doors and smaller pieces inside the crankcase. The casualty also resulted in significant damage to the lower liner landing surface and the engine’s crankshaft.

Goltens thoroughly inspected the obvious damage and performed crack testing on other areas to ensure all damage was identified. Goltens assured the customer that the block was not condemned and could be repaired in place with a combination of metal stitching and in-situ machining.

WARTSILA 18V32LN ENGINE BLOCK REPAIR

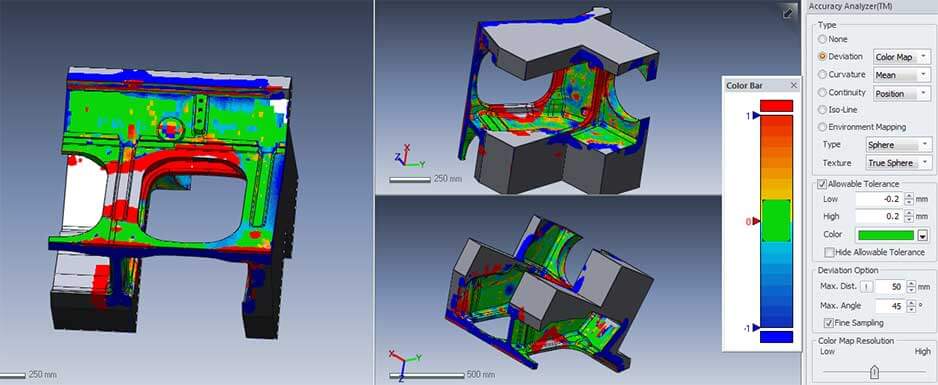

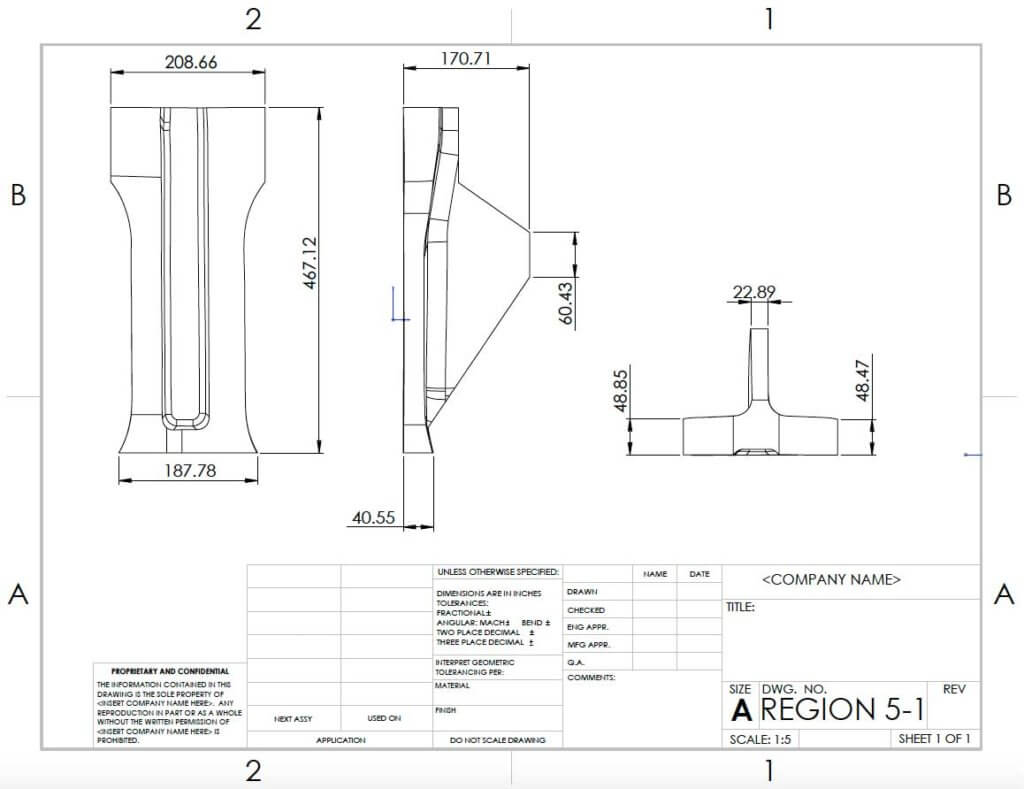

Goltens performed laser scanning on the damaged areas to facilitate the casting of precise inserts for the block. Goltens cropped the damaged interior and exterior sections of the engine to ensure clean mating surfaces and then measured the areas for the fabrication of cast inserts to be stitched into the block. The inserts were carefully positioned and metal stitched into place using Lock-n-Stitch tooling. With metal stitching complete, Goltens machined the stitched surfaces and performed thorough crack testing to ensure the repairs were successful.

To repair the damage to the liner landing surface, Goltens line bored the damaged bore and installed a sleeve insert and machined it to standard diameter.

ENGINE BLOCK REPAIR RESULTS

What appeared to be a potentially condemned engine was a routine, albeit high precision and challenging, repair for Goltens experts. The block repairs were thoroughly checked and cleared before Goltens moved on to repair the damage to the engine’s crankshaft.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download PDF