Goltens forms a new bond in cement factory with metal stitching

Sulzer 16ZV40-48 diesel generator

Goltens received an urgent enquiry to mobilize tools and In Situ technicians to Southern Province Cement Company (SPCC) in Jazan southern Saudi Arabia to carry out repairs on one of their power plant generators.

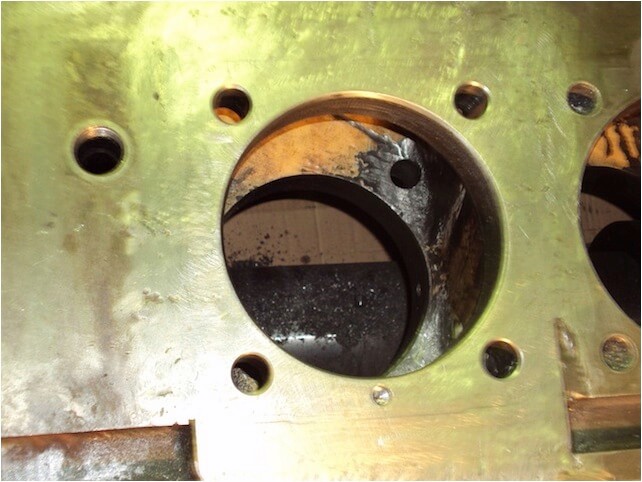

Engine number 7, a Sulzer 16ZV40/48 had a badly damaged fuel pump mounting area rendering the engine inoperable and forcing the plant to operate at reduced capacity. Given the plant’s contractual obligations for delivery of product, the repair and return of the engine to production was a top management priority making repair schedules and pressure very tight.

Inspection using dye penetrant revealed that the damage was much greater than expected with all four fuel injection pump mounting bolt areas significantly damaged. The difficulty for repair was compounded by a prior attempt to repair the block by welding

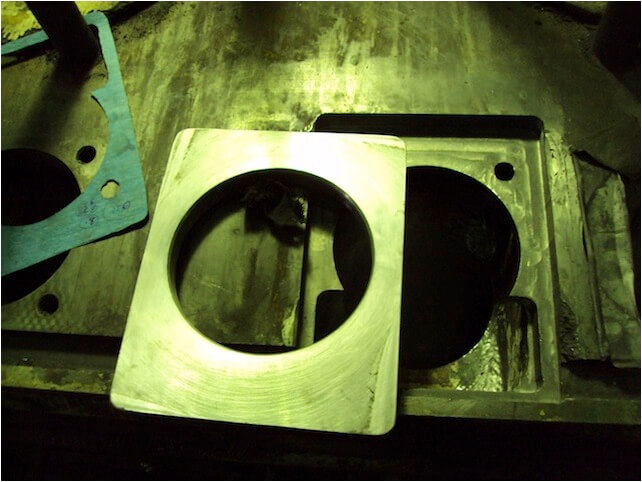

Goltens proposed to mill out the damaged area and fabricate a form fit insert to be metal stitched into place to repair the block.

Goltens milled out the damaged area and completed post machining dye penetrant checks to ensure that 100% of the damage had been removed. Goltens fashioned a template of the damaged area and fabricated an insert that was machined to fit neatly in damaged area of the block.

Goltens’ in-situ machinists, well trained and experienced in Lock-n-Stitch metal stitching, secured the insert in place with clamps and made initial stitches to secure the insert before stitching the full periphery to ensure maximum strength was obtained.

Post metal stitching, the full surface of the insert was given a light machining skim to ensure that it was level with the rest of the block. The final step of the job was to pitch and drill all the holes for fuel pump mounting bolts using a portable drilling machine.

Post drilling, the new fuel pump mounting insert was tested by loading the bolts to 300kg. The load test was successful and rebuilding of engine was resumed.

PROJECT FACTS

| SPCC Generator | |

|---|---|

| Engine Make/Model: | Sulzer 16ZV40/48 |

| Insert Dimension: | 350mm x 250mm |

| Insert Thickness (min/max): | 22mm/36mm |

| Location: | Saudi Arabia |

REPAIRS

- NDT inspection of the damaged area

- Milling damaged area from the block

- Post machining NDT

- Fabrication of form fit insert

- Metal stitching of insert

- Finish machining of block surface

- Load testing to 300KG on repaired surface

RESULTS

The entire job was carried out faster than originally estimated minimizing the down time of the generator. The complete job was completed in only seven days from Goltens’ arrival onsite, allowing the customer to resume the rebuild of the engine and continue production.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now