Bergen 32:40L9P Crankshaft Replacement

BERGEN 32:40L9P MAIN ENGINE CRANKSHAFT REPLACEMENT IN SINGAPORE

The cargo ship SE Cerulean suffered a major crankshaft failure on its port side main engine. As the maximum allowable undersize for this crankshaft was only 2.0mm, the owner decided to replace the crankshaft rather than try to salvage it by machining.

PLANNING & PREPARATION

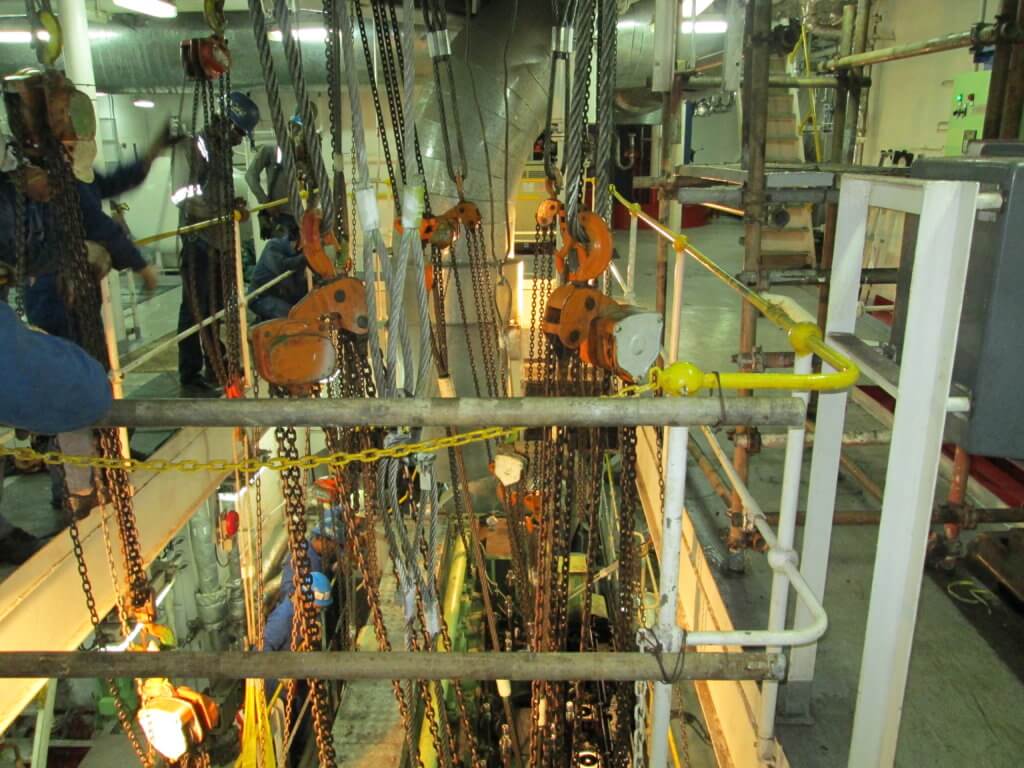

After surveying the vessel for rigging logistics, Goltens prepared all required lifting brackets and rigging gear at its work shop and reviewed the repair schedule and timeline with the customer. Goltens then mobilized the tools and a team capable of working non-stop to Keppel shipyard to effect the repairs.

ENGINE DISMANTLING

All Main engine components – cylinder heads and liners, pistons, connecting rods, fuel pumps and injectors, lube oil and fresh water pumps and air cooler were dismantled and brought to Goltens’ workshop for inspection and control measurements. The engine block lifted and old crankshaft removed and sent to the Goltens workshop for survey.

CRANKSHAFT REPLACEMENT AND REBUILD

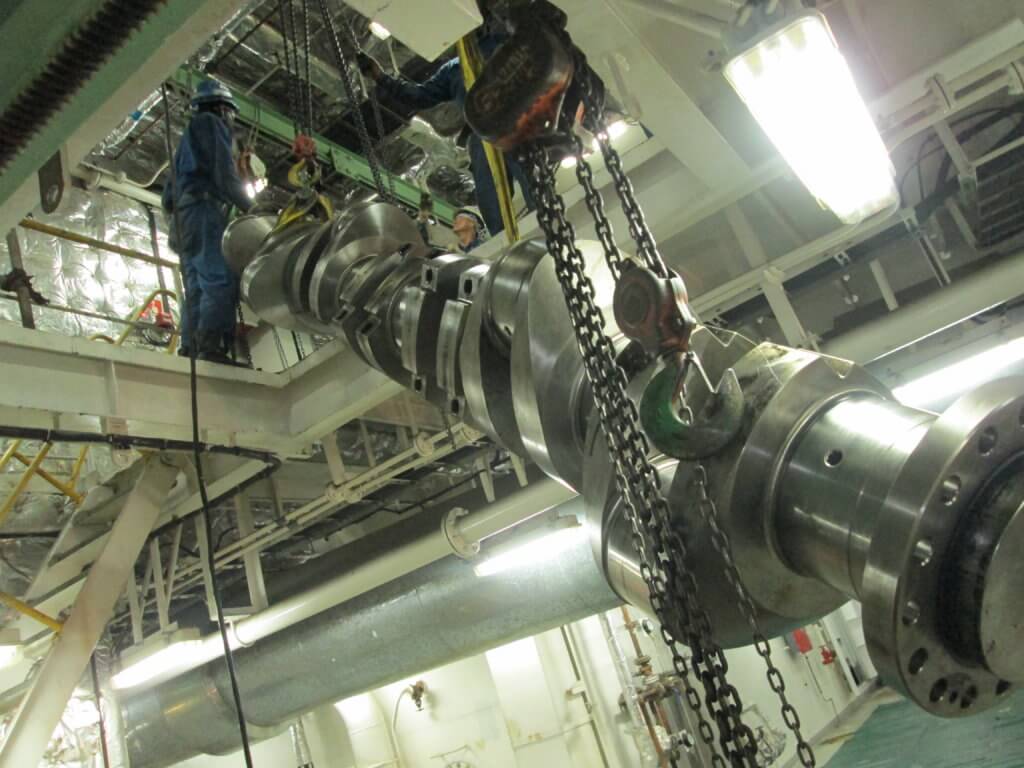

The new crankshaft was inspected in the presence of the surveyor at Goltens’ workshop and all the measurements were well within the maker’s tolerances.

The crankshaft was then transferred to the vessel and contact tests between the crankshaft webs and counter weights was completed. The flywheel and vibration was damper fitted and reaming of the fitted bolts holes completed. Old crankshaft gear from the condemned shaft transferred to the new shaft as per maker guidelines.

The new crankshaft was then rigged into the engine room and assembled with new bearings. The engine was then rebuilt with the components overhauled at the workshop. New connecting rods were installed after cracks were discovered in the serrations.

As final preparations for engine commissioning and testing, Goltens laser aligned the engine and completed Chockfasting of the engine foundation.

SEA TRIAL AND RESULTS:

After flushing the internal and external lube oil systems, the running in program and load trials were completed per maker guidelines.

The vessel completed engine trial in the basin followed by full sea trial at 100% load. The full repair was completed per the planned schedule and the vessel returned to service.

CUSTOMER COMMENT:

“M/V Cerulean sailed out today morning with successful repair of the port engine. I would like to thank your entire team and exceptional support from office and workshop. Very well job done!!!”

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now