Turnkey BWT Retrofit With Zero Downtime For Offshore Supply Vessel

3D Scanning, Design, Prefabrication And Installation For Optimarin (OBS)

The Highland Monarch, owned by Gulf Offshore N.S. Ltd., is an offshore supply vessel operating from The Netherlands. The retrofit project is the latest in a multi- year retrofit program for the entire Gulf Offshore fleet.

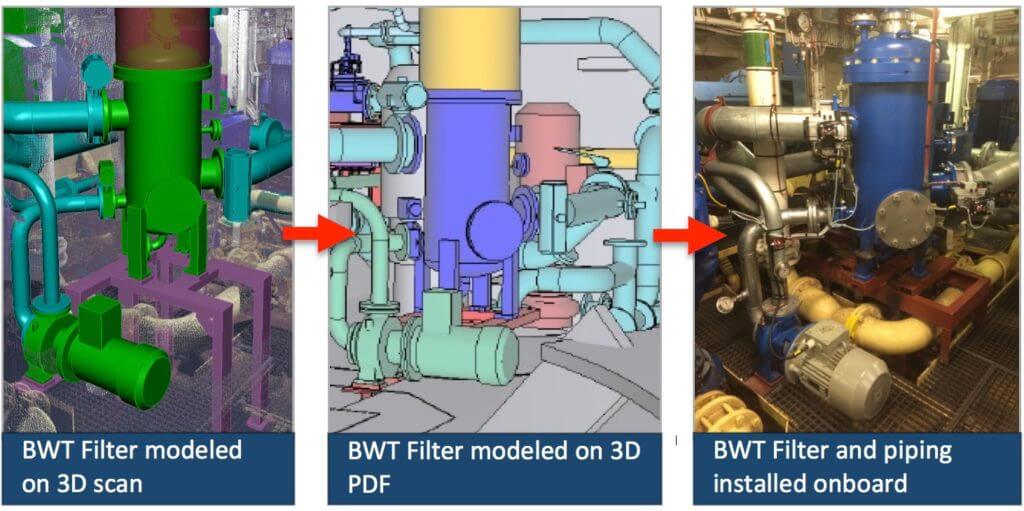

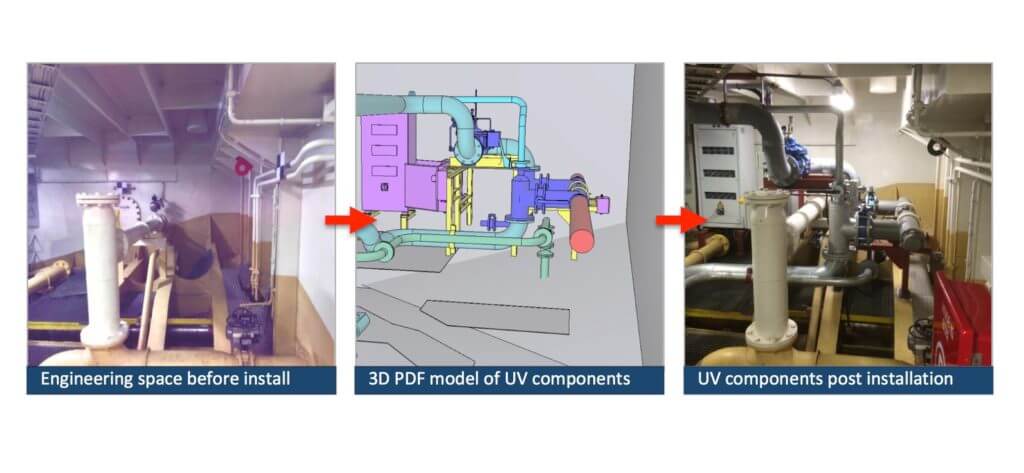

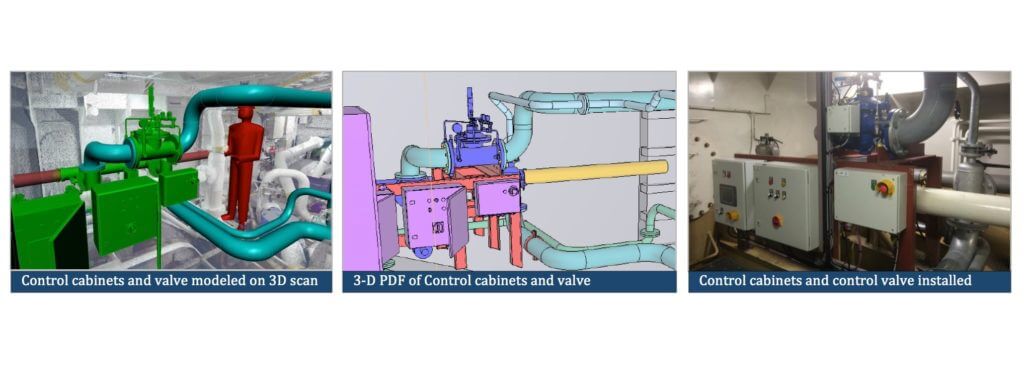

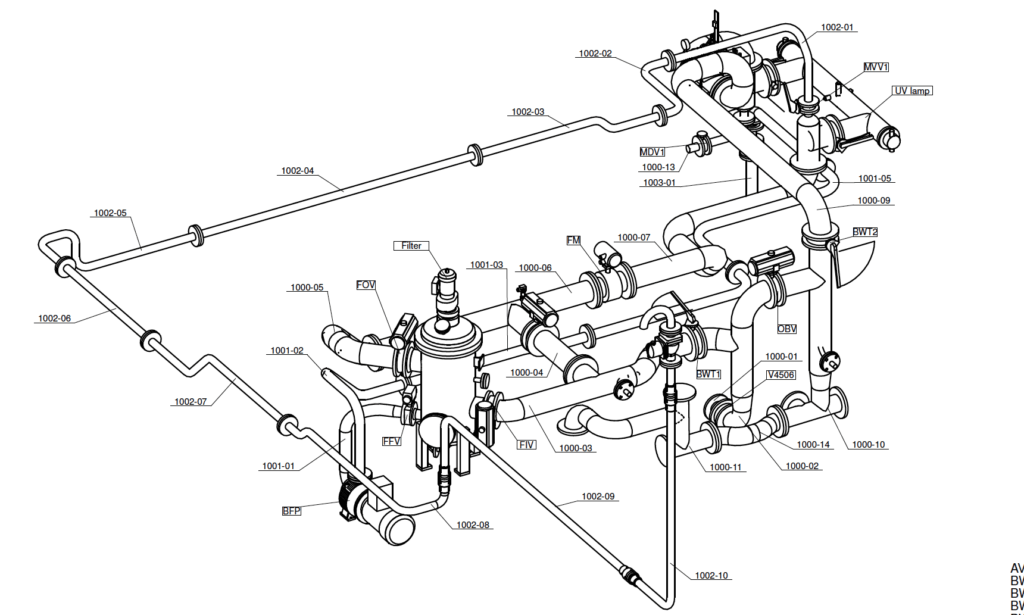

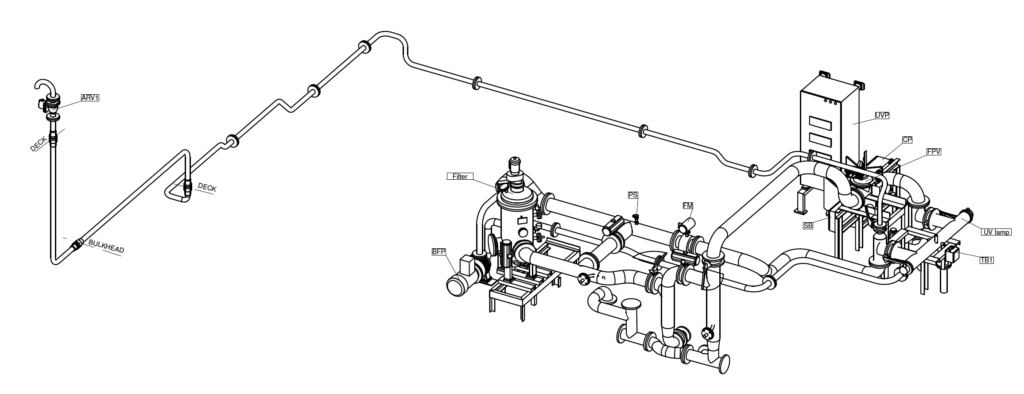

The project started with a 3D laser scan and shipboard survey to determine the best options for placing and installing a BWT system. Using the 3D scan output, an extremely precise 3D model of the BWT system was created to verify placement and fit, as well as account for any collisions or modifications required. Using this output, detailed engineering was completed to the same accuracy (± 2.00mm) enabling Goltens to prefabricate all piping, foundations and connections for onboard installation. As the piping was all fabricated to the same accuracy as the scan, no onboard fitting was required and all piping could be pre-galvanized saving significant time onboard.

Since the vessel had no existing overboard connection for the BWT system, a new overboard was installed by divers while the vessel was afloat and off-hire for only 6 hours

The rest of the BWT system installation was done during normal operations while the vessel was in port. After mechanical installation was complete, electricians boarded the vessel for 3 days and completed all electrical work while the vessel was at sea.

PROJECT FACTS

| HIGHLAND MONARCH | |

|---|---|

| Ballast Water System: | Optimarin Ballast System (OBS) |

| Ballast flowrate: | 167 m3/hour |

| Vessel Type: | Offshore Supply Vessel |

| Owner: | Gulf Offshore N.S. Ltd. |

TURNKEY BALLAST WATER RETROFIT SCOPE:

- 3-D Scanning and Modeling

- Detailed engineering

- Prefabrication of all required components

- Installation of new ballast piping and connection to the ballast treatment equipment

- Pulling cables for the new electrical connections

- Adding new cable trays and hooking up to the vessels automation system

- Connecting new pneumatic valves to ships control air

- Connecting de-aeration piping up to the main deck

- Making a new overboard connection with the assistance of divers – no dry docking needed

- Placing extra vibration supports on new piping

OPTIMARIN BWT RETROFIT RESULTS:

Goltens completed the turnkey retrofit work with zero downtime for the vessel. Goltens continues its work to retrofit the entire Gulf Offshore supply vessel fleet.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now