Tight timelines met on BWT retrofit for advanced pipelay vessel

3D scanning, design, prefabrication and installation supervision for Optimarin ballast system for Technip

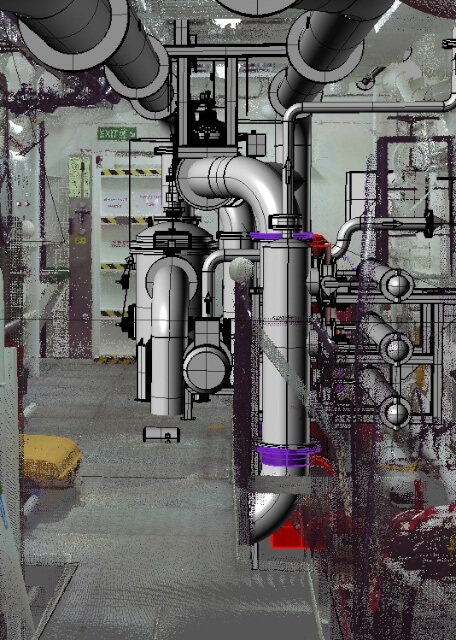

In November 2012, Goltens received the order for 3D Laser scanning and delivery of a detailed engineering design package and associated piping for the installation of an Optimarin ballast water treatment system (OBS) on the Apache II, an advanced pipelay vessel.

The customer, Technip, a world leader in project management, engineering and construction for the energy industry, operates a global fleet of 32 specialized vessels for pipeline installation and subsea construction, and required a tight timeline as the vessel was scheduled for drydock in January 2013. As such, all scanning, design and prefabrication had to be completed ahead of time.

Goltens Green Technologies experts joined the vessel in Invergordon, Scotland in early December to complete the one-day scanning of the engine room space where the system was to be installed. Seventeen days later, Goltens delivered the complete engineering package and began prefabrication of all required piping and components to install the system.

The vessel went into dry dock in the Netherlands in mid January and Goltens delivered the prefabricated piping to the shipyard. The installation work was completed under supervision of Goltens and project status was reported to the vessel superintendent daily. Progress and actions were discussed with the parties involved during morning meetings to keep the project on track.

PROJECT FACTS

| APACHE II | |

|---|---|

| Vessel type: | Advanced Pipelay Vessel |

| Ballast flowrate: | 500 m3/hr |

| Total ballast capacity: | 5,746 m3 |

| Ballast treatment system: | Optimarin OBS 500 m3/hr |

BALLAST WATER TREATMENT RETROFIT WORK

- 3-D Scanning and Modeling

- Detailed engineering

- Prefabrication of piping

- Supervision during installation and commissioning

BWT RETROFIT RESULTS

Due to the fact that a lot of jobs were planned for this dry dock, working efficiently together with all the parties involved was a challenge, but the project was completed on schedule and did not result in any delays in the vessel’s departure from the yard. The total piping and electrical installation project, including commissioning, took 4 weeks to complete.

CUSTOMER TESTIMONIAL:

“During an extremely busy dry docking, Goltens provided a first-class project management solution for the installation of a Ballast Water Treatment System onboard the Apache II. A 3D scan was made and a detailed installation plan was produced which allowed vessel and onshore technical staff to fully understand the system complexities. From this data, Goltens were able to produce the majority of the pipework off-site and project managed the installation phase on behalf of Technip, controlling the shipyard and sub-contractor workforce.”

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now