Steam Turbine Repair Using In-Situ Shaft Machining Restores Full Capacity Of Dutch Powerstation In Only Four Days

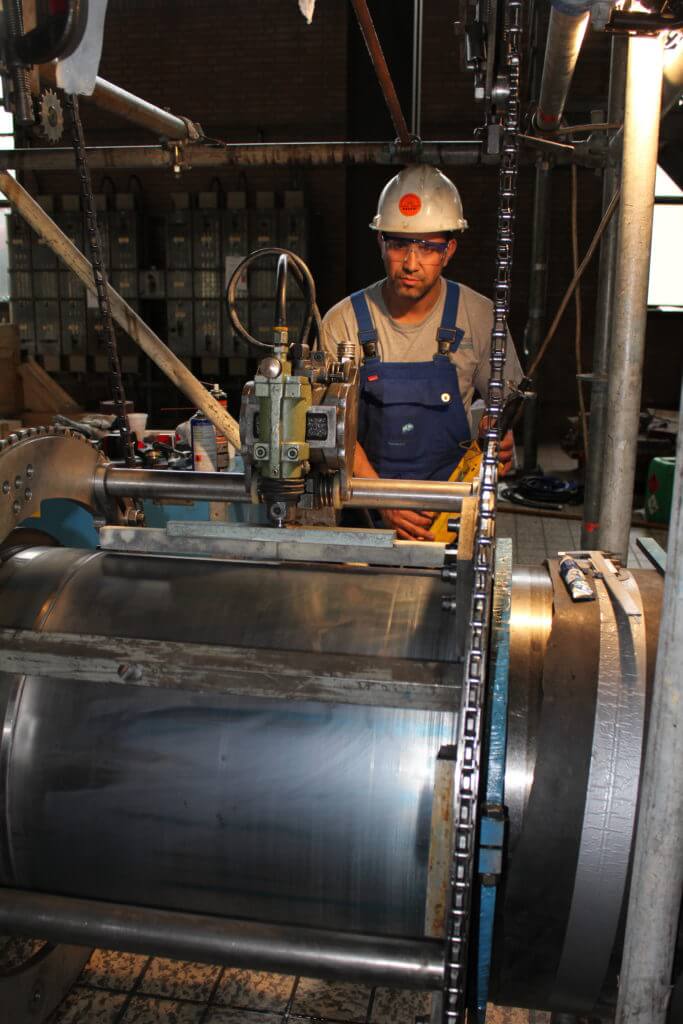

Machining and honing of steam turbine generator rotor shaft

During operations at one of the power stations of a major European electrical supplier, a lack of lubrication caused damage to one of the rotor shafts. The power station operators asked Goltens’ experienced In-situ engineers to evaluate the situation and determine the correct repair procedures.

After inspection of the shaft-end by Goltens’ engineers, it was proposed to machine the shaft in-place to minimize the cost of the repair and the downtime of the generator.

Only 1 day after receiving the requisition from its customer, Goltens started the in-situ machining procedures on the 530 mm shaft. Goltens’ engineers worked in day and night shifts to speed up the steam turbine repair process and minimize the downtime of the installation as much as possible.

PROJECT FACTS

| COAL/BIOMASS STATION | |

|---|---|

| Station Output: | 585 MW |

| Shaft Diameter (Pre-Machining): | 530 mm |

| Shaft Diameter (Post-Repair): | 528.5mm (-1.5mm) |

| Finished surface roughness: | 0.2 Ra |

| Repair Time: | 4 Days |

STEAM TURBINE REPAIRS CONSISTED OF:

- Inspection of the damaged shaft

- Installation of machining tools and equipment

- Machining of rotor shaft-end to undersize -1.5 mm (528.5 mm)

- Honing of rotor shaft-end to obtain final roughness of 0.2 Ra

- Inspection of end result and checking of straightness and surface roughness

IN-PLACE MACHINING RESULTS:

Working around the clock with multiple teams, the shaft- end was machined and honed to a final diameter of 528.50 mm with a surface roughness of 0.2 Ra. The plant was then ready to rebuild the generator to restart the generation process.

Goltens’ in-situ machining and honing services enabled the customer to restore the full generation capacities within several days limiting the cost of lost production. The customer was satisfied with the end result and swift cooperation with Goltens’ In-Situ Machining specialists.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now