Multi-Station Cooperation Leads to Another Efficient BWTS Retrofit Installation

GOLTENS GREEN IN THE NETHERLANDS AND CHINA TEAM UP FOR ALFA-LAVAL RETROFIT

A European tanker owner approached Goltens Green Technologies in The Netherlands to support the retrofit of an Alfa-Laval Pure Ballast BWTS system on their 6-year-old, 50,000 DWT, Chemical/Products Tanker.

SCANNING AND DESIGN:

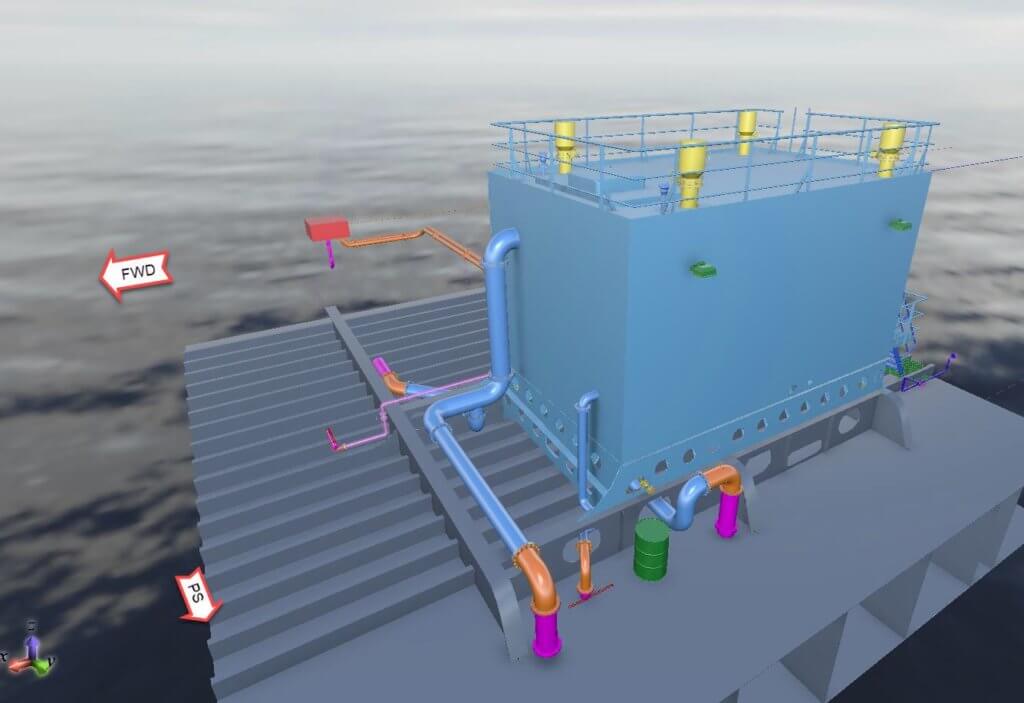

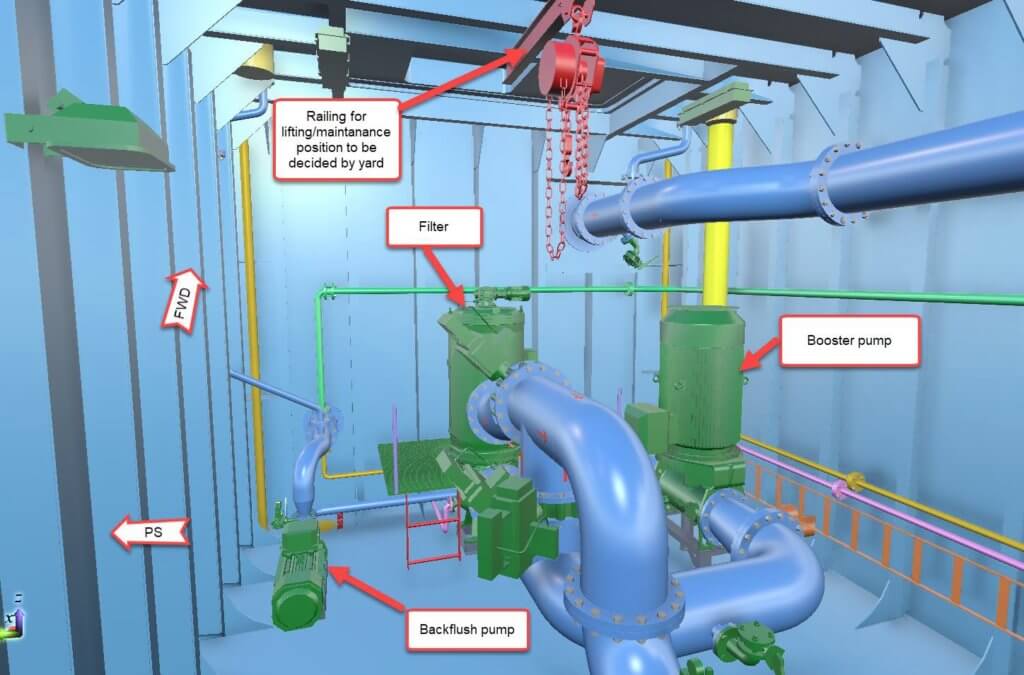

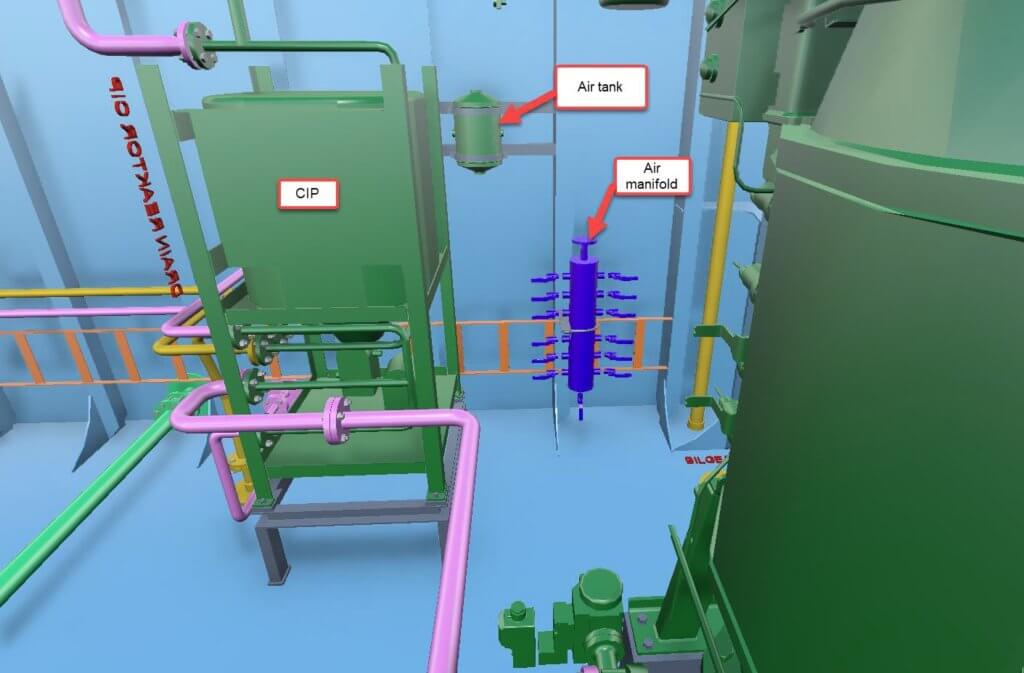

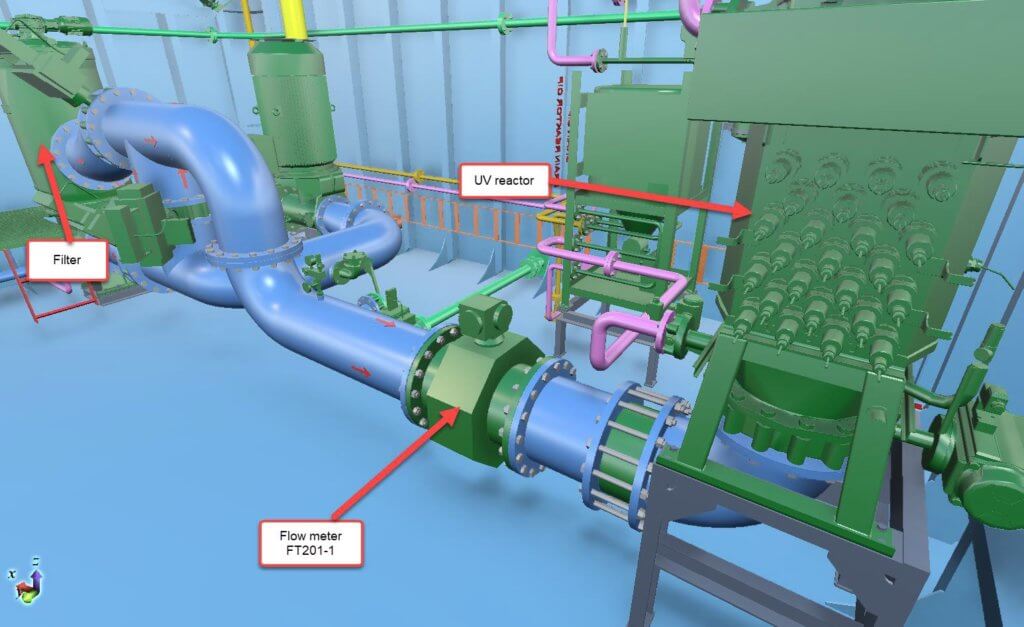

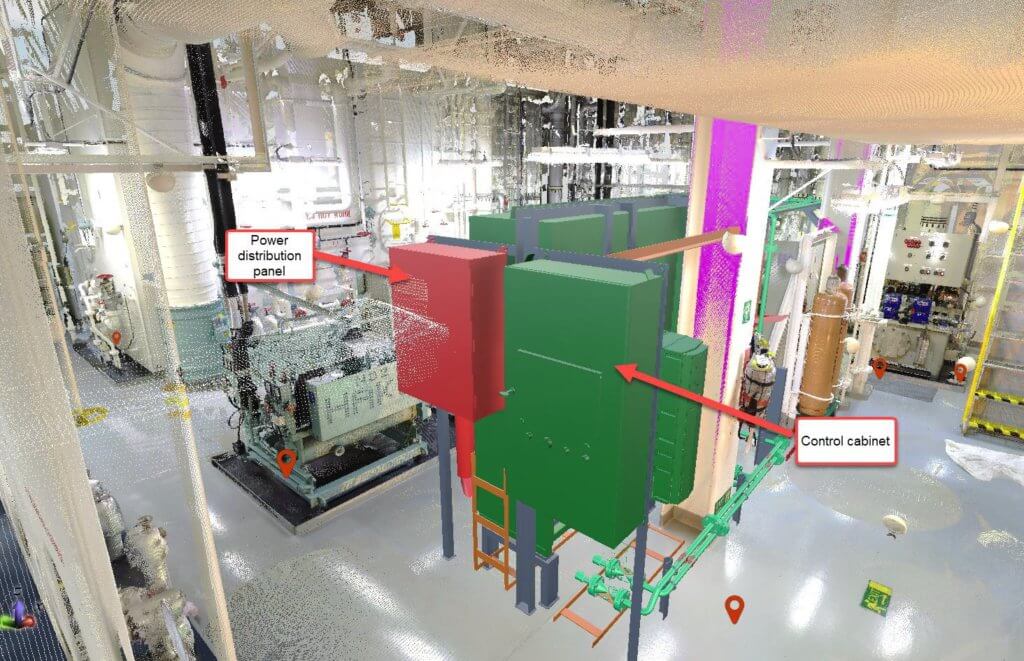

Survey & 3D Scanning: Goltens resources from Europe attended the vessel to perform the ship check and conduct 3D scanning of the spaces considered for installation. As the retrofit being considered was a deckhouse on main deck, the survey had to extend beyond the main engineering spaces.

3D Modeling and Detailed Engineering: Using the 3D scan data, basic modeling of the system was completed and reviewed by the parties involved. Once approved Goltens’ design engineers completed the detailed engineering packages required for the retrofit and worked to secure class approval for the retrofit on behalf of the customer.

INSTALLATION AND SUPERVISION:

The customer selected a repair shipyard in Shanghai to complete the retrofit installation and Goltens arranged for one of its BWTS Retrofit Engineering Supervisors to attend to support and oversee the installation.

To limit the time in drydock, the deckhouse was prefabricated by the shipyard prior to the vessel’s arrival. With the scanning and design accuracy of +/- 2mm, the deckhouse and other components could be fabricated to tight tolerances allowing for an efficient and highly accurate installation.

Once the vessel was in the drydock, the installation was successfully completed in only 14 days including site preparation and COVID related delays.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now