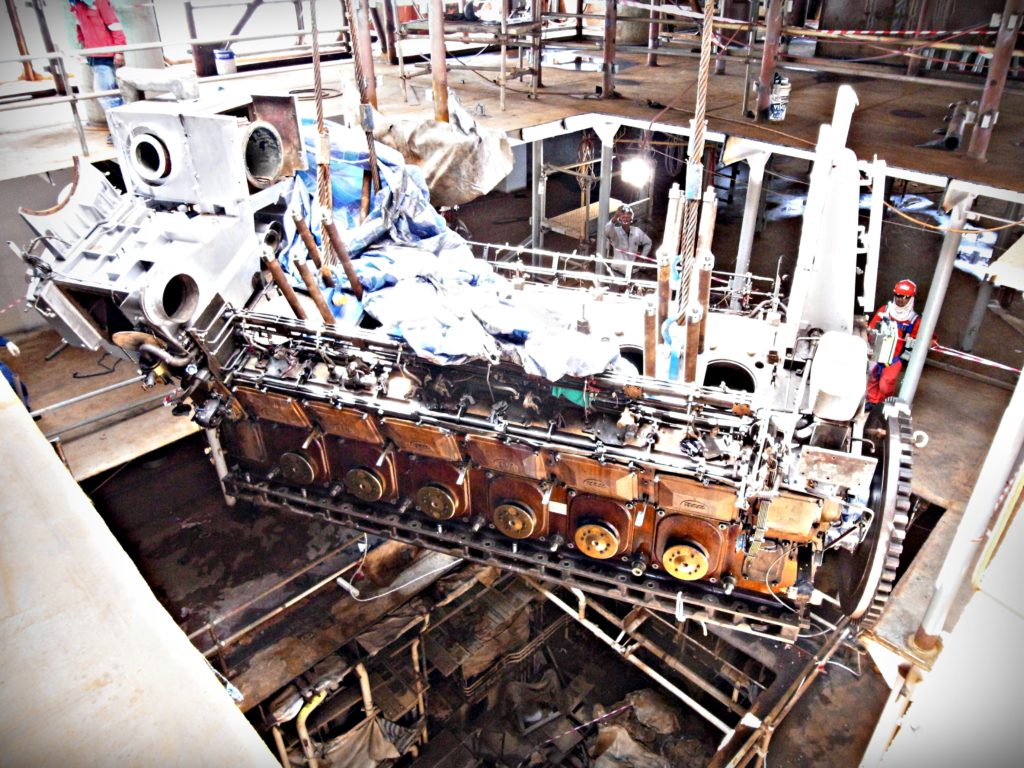

Complete MAN B&W 12V32/40 engine overhaul and line boring

Vessel conversion in Batam, Indonesia

A 17 year old vessel was undergoing conversion to a Livestock Carrier in Batam Indonesia and the vessel’s owners concluded that the vessel’s MAN B&W 12V32/40 main engine was not in working condition.

Goltens’ detailed inspection revealed the engine was in very poor condition and would require full overhaul. Inspection indicated the crankshaft journals should be polished and laser checks of the of the bore alignment showed the engine would need to be line bored as well. Given the extremely tight space in the engineroom, the challege was to find the most efficient solution for the full repair.

PROJECT FACTS

| DIAMANTINA | |

|---|---|

| Customer: | Ocean Eight Shipping |

| Engine Make/Model: | MAN B&W 12V32/40 |

| Work Location: | Batam, Indonesia |

THE SOLUTION

Given the restricted space for line boring and the magnitude of the required repairs, Goltens determined the best approach would be to remove the engine block from the engineroom and complete the required in-situ line boring in the yard’s workshop. Goltens’ diesel experts, disassembled the engine and rigged the block and the crankshaft shoreside for the repair. Simultaneous with this, Goltens arranged for the supply of the liners, bearings and other spare parts required for the engine overhaul.

Prior to line boring, Goltens specialists completed straightness checks on the foundation and dye penetrant checks on the main bearing pockets to make sure there was no additional damage. Once satisfied on the magnitude of the damage, Goltens proceeded to line bore the engine, polish the crankshaft and blue fit the crankshaft counterweights. Goltens then installed the crankshaft and main bearings and rigged the block back into the engineroom for reassembly with the supplied spares.

JOB EXECUTION

Once the engine was fully overhauled and reassembled, the engine was flushed, laser aligned and chocked before operational testing and full sea trials. During sea trials, the engine was succesfully tested on both MDO and HFO with 75% load at 14 to 16 knots with all engine parameters within the acceptable range.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now