In-Situ Machining for Norwegian Hydroelectric Power Plant

New impeller installation requires machining modification

Andritz Hydro was contracted to manufacture and install a new impeller for the Hunsfos hydroelectric power plant in Vennesla, in southern Norway

The goal of the project was to increase the efficiency of the power plant. In order to accommodate the new impeller, Andritz Hydro recognized that they would need to have the turbine outlet machined to a larger diameter.

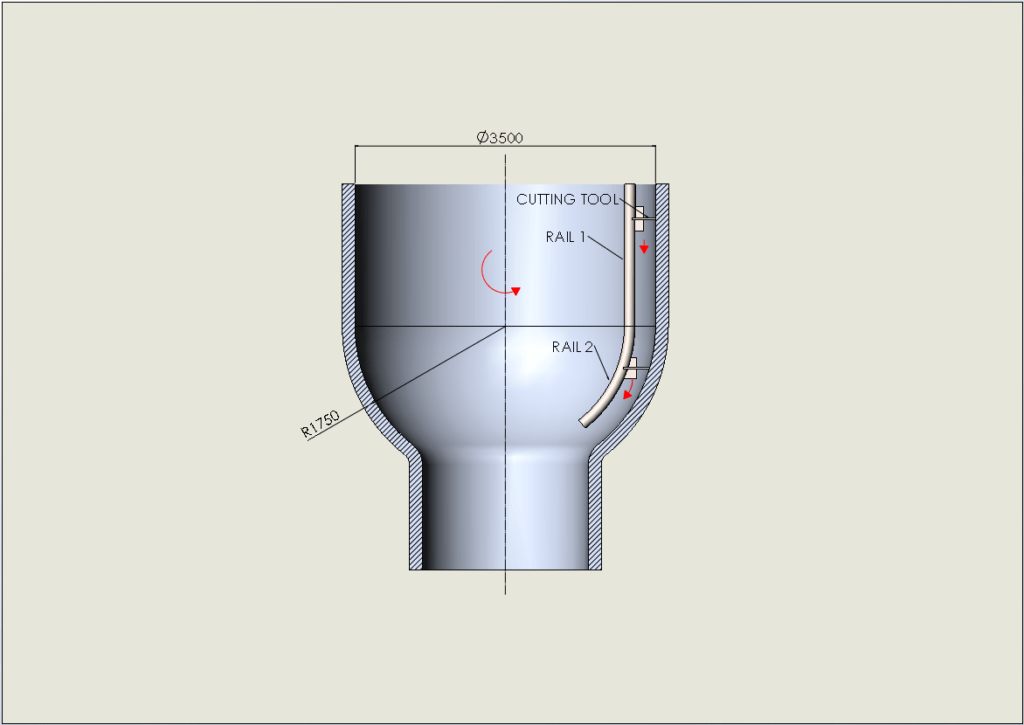

Goltens was contacted to evaluate the job and propose a solution. The job was far from simple in that the inside diameter of the outlet was roughly 3.5 meters and the surfaces to be machined were in some places flat and in others curved. Further complicating the job was the restriction on where Goltens could weld to secure the machining tooling in place.

Goltens evaluated the challenge and presented Andritz with a proposal for the completion of the complex job. Goltens in-situ technicians modified their existing tooling to accommodate the requirements by fabricating a rail that followed the exact radius of the curved surface for the machining bit to follow. Once tested, they deployed the tooling and a 3 man in-situ machining team to complete the job.

PROJECT FACTS

| HUNSFOS HYDROPOWER PLANT MACHINING | |

|---|---|

| Turbine Type: | Kaplan |

| Plant Power Output: | 77.6 Million KW hrs/yr |

| Turbine Outlet Diameter: | 3,500mm |

| Vertical Surface Machined: | 800mm |

| Curved Surface Machined: | 300mm |

| Material Removed from Radius: | 3.5mm |

IN-PLACE HYDRO MACHINING SCOPE:

- On-site inspection of outlet housing

- Fabrication of special cutting assembly

- Machining an average of 3.5mm off the radius of the 800mm vertical surface and 500mm curved surface

IN-PLACE MACHINING RESULTS:

A three-man team from Goltens Oslo did this job in a period of 25 days, taking away an average 3.5 mm on the radius.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now