A matter of millimeters – no room to spare

Annealing saves main engine crankshaft for owner after failed attempt to machine away the hardness

Resistance to new repair methods can prove costly. A bulk carrier operator almost learned this lesson when they chose a traditional machining method to address excessive hardness. The 13-year-old bulker’s main engine, an MAN B&W 6S50MC-C, suffered a lube oil failure resulting in heavy damage to crankpin #6.

Goltens advised that the journal could, and should, be rectified by annealing and machining. Goltens believed that the hardness would extend below the rated diameter of the journal and that traditional methods to machine below the hardness would result in a condemned crankshaft.

DANGEROUSLY CLOSE TO THE LIMIT

The owner opted to go with a competitor and allowed them to machine more than 5.00mm, dangerously close to the 6.00mm limit, from the 600.00mm crankshaft diameter. With less than half a millimeter remaining within the rated diameter, the hardness levels were still too high for either class or the maker to accept. Machining the journal beyond -6.00mm with hardness still present would condemn the shaft. At this point, looking for a solution, Goltens was requested to engage to try to salvage the crankshaft with only a fraction of a millimeter to work with.

THE PROVEN PROCESS

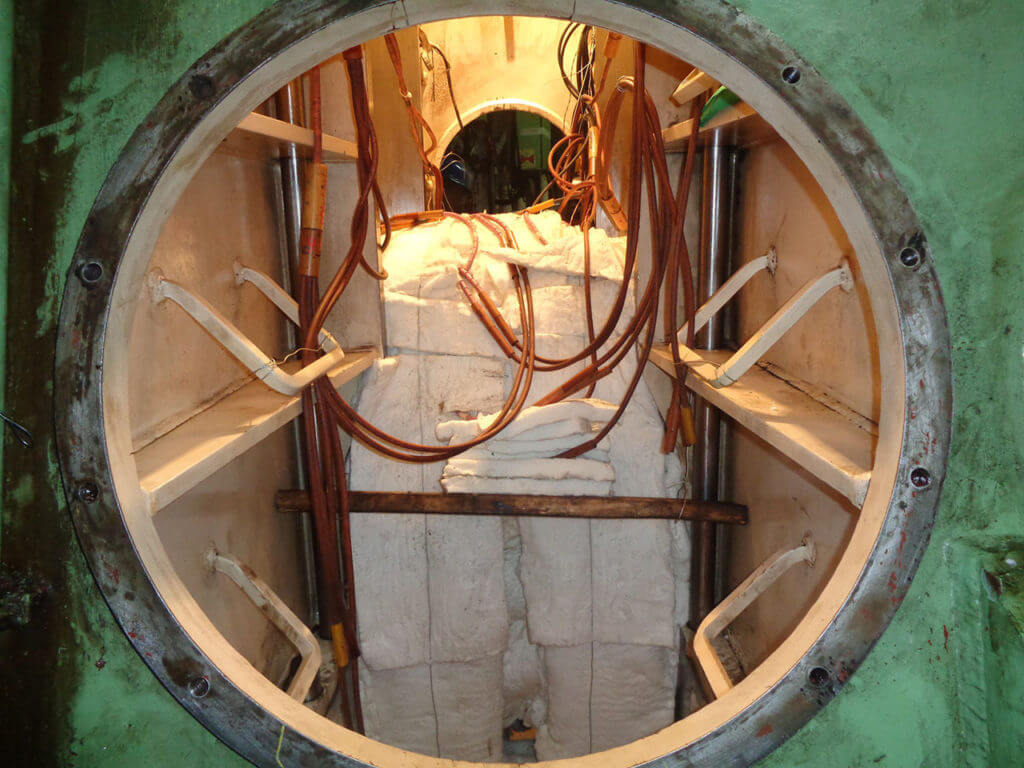

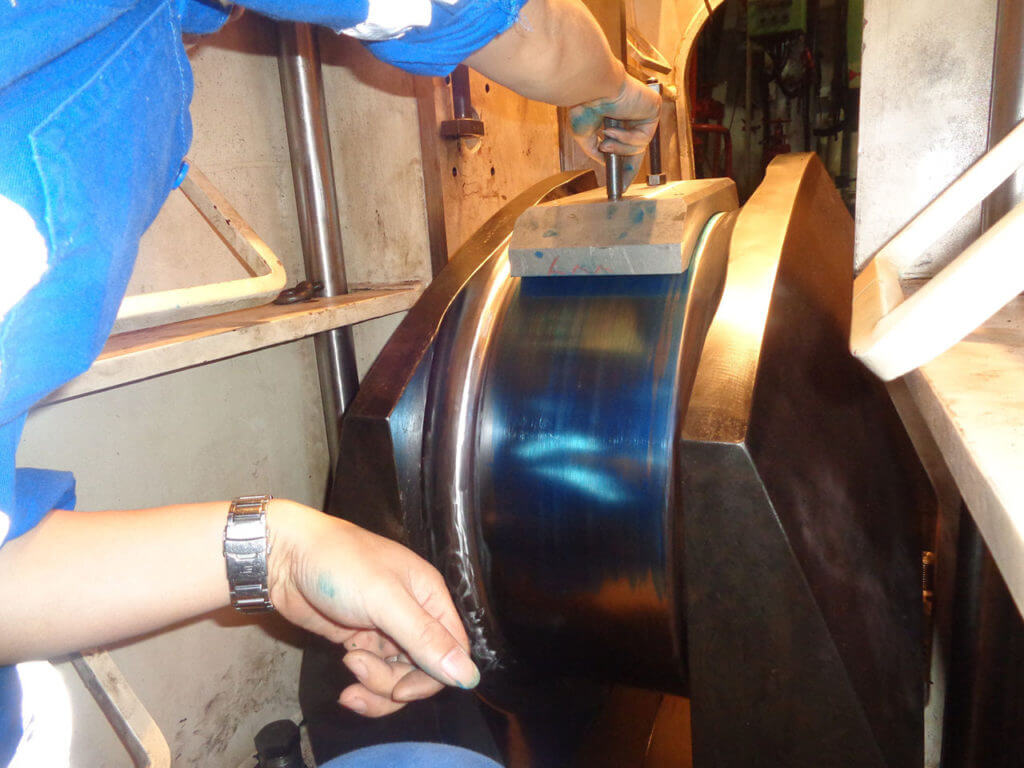

Goltens deployed its tooling and machinists to the vessel and inspected the condition of the shaft and found a significant section with excessive hardness still present. Goltens executed its proven annealing process to remove the hardness and carefully machined and final polished the journal to remove the final few tenths to finish the job within the rated diameter at -6.00mm. The team completed the process in seven days time.

THE LESSON

The owner almost lost the crankshaft and incurred the enormous costs associated with the purchase, transport and installation of a replacement, not to mention significant avoidable downtime. By applying annealing before it was too late, the crankshaft was salvaged and the vessel returned to service, albeit with less remaining shaft material than would have been, if the owner had pursued annealing from the start.

PROJECT FACTS

| MAIN ENGINE ANNEALING | |

|---|---|

| Engine Type: | MAN B&W 6S50MC-C |

| Location: | China |

| Crankpin Diameter (Orig.): | 600mm |

| Final Crankpin Diameter: | 594mm (-6.00mm) |

| Hardness Pre/Post Annealing: | 608HB/220-310HB |

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now