7 engine overhaul keeps drill ship operational with no down time

HiMSEN 9L 32/40 & 18V 32/40 8,000 hour engine overhauls in the Gulf of Mexico

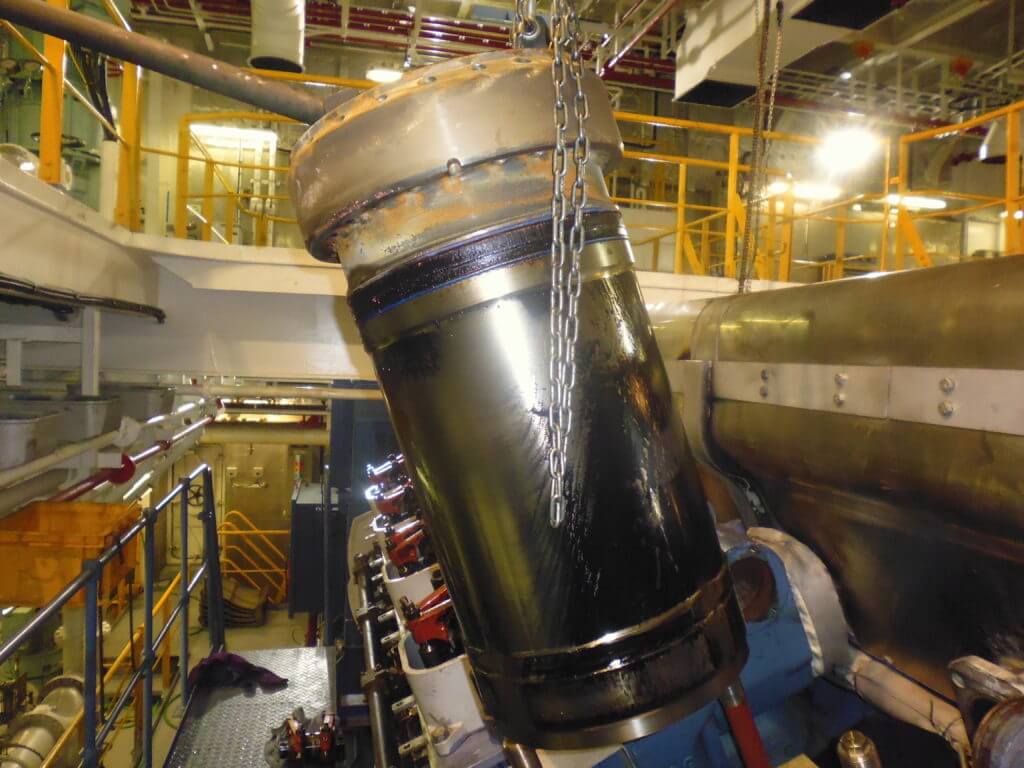

A major offshore drilling operator contracted Goltens Houston , to provide complete service maintenance and supervision for the 8,000-hour overhauls on 7 of the Mobile Offshore Drilling Unit’s Hyundai HiMSEN engines. Six inline 9L32/40 engines and two 18V 32/40 engines power the drill ship.

As minimizing downtime is critical for any offshore drilling vessel, Goltens mobilized its offshore-certified diesel technicians to work in 12-hour shifts. Goltens’ service engineers worked efficiently, with the support of the ship’s crew, to complete the maintenance on each engine and restore it to operation before moving on to the next engine to provide maximum power availability to the vessel and allow it to operate without interruption.

PROJECT FACTS

| 7 ENGINE OVERHAUL | |

|---|---|

| Vessel Type: | Mobile Offshore Drilling Unit |

| Work Location: | Gulf of Mexico |

| Engine Make/Model: | HiMSEN 9L32/40 & 18V32/40 |

| Engine Output: | 4,500 kW & 9,000 kW |

| Engines Overhauled: | Six in-line & One V-type |

HIMSEN 9L & 18V 32/40 ENGINE OVERHAUL SCOPE

- Verify torque on all major components.

- Measure crankshaft deflections

- Removal and inspection of one complete cylinder unit including; cylinder head, liner, piston and connecting rod

- Visual inspection of gear train, camshaft and swing arm roller bearing

- Inspection of all fuel pumps

- Removal of all injectors; changing out internal parts, pop test of each injector, and reinstallation.

- Check tappet clearances

- Reassembly, commissioning and run-in of each engine per manufacturer’s guidelines.

HIMSEN 9L 32/40 AND 18V 32/40 OVERHAUL RESULTS

Goltens’ diesel team worked on all 7 engines without interruption, ensuring that the engines were overhauled safely and efficiently. Operational tests reflected all operational performance measurements were within tolerances prior to delivering the engines to the customer.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now