Turnkey Optimarin Ballast Water Treatment Retrofit

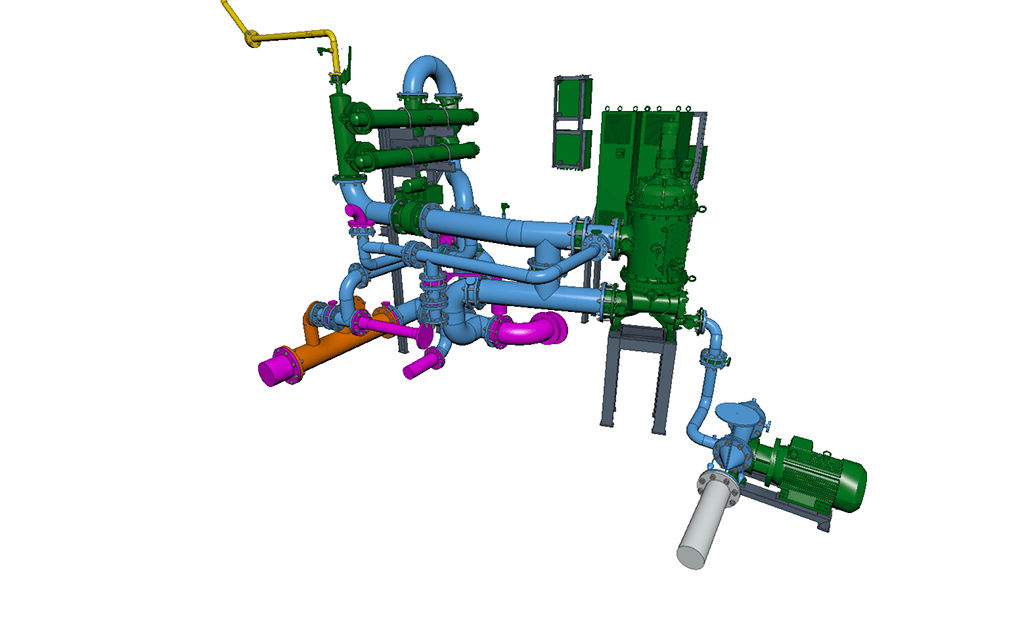

SCANNING, DESIGN, PREFABRICATION AND INSTALLATION OF AN OPTIMARIN OBS SYSTEM

A leading seismic survey vessel operator selected Optimarin’s 334m3/hour OBS ballast water treatment system for one of its research vessels. Goltens had previously completed two successful retrofits for this owner and was awarded this retrofit as well. The timeline was relatively short with only a 3-month window between project kick off and completion of the installation.

SCOPE OF WORK:

Having completed hundreds of ballast water retrofits on systems much larger with greater design challenges, Goltens was confident it could meet the deadlines. The scope was for a turnkey delivery inclusive of:

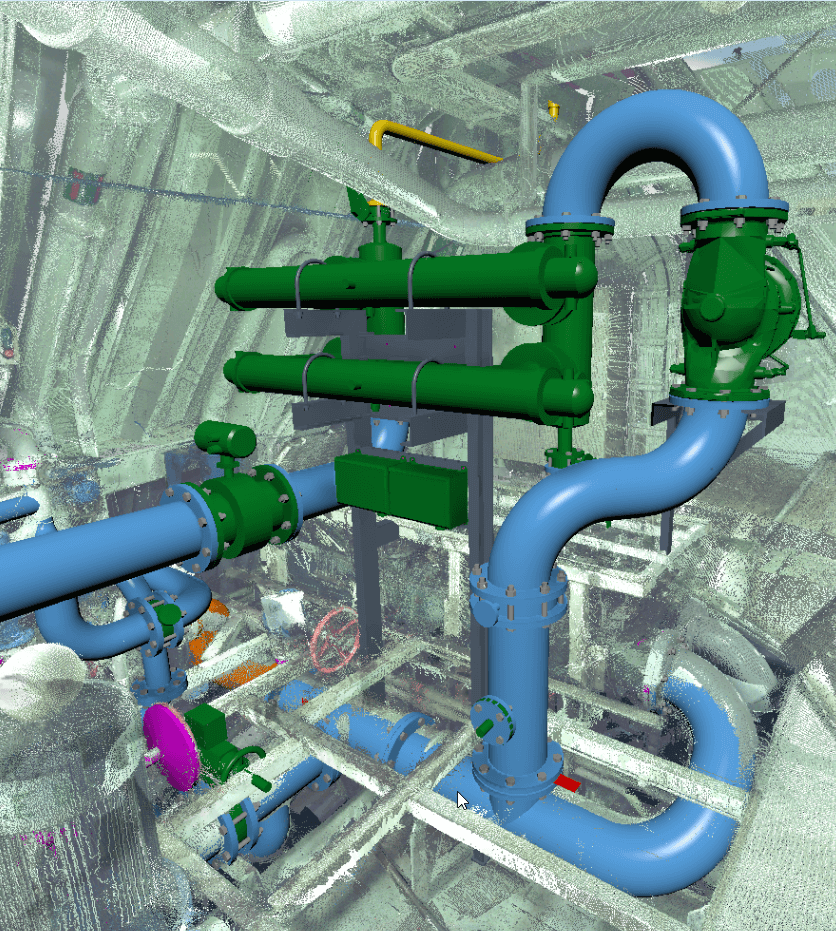

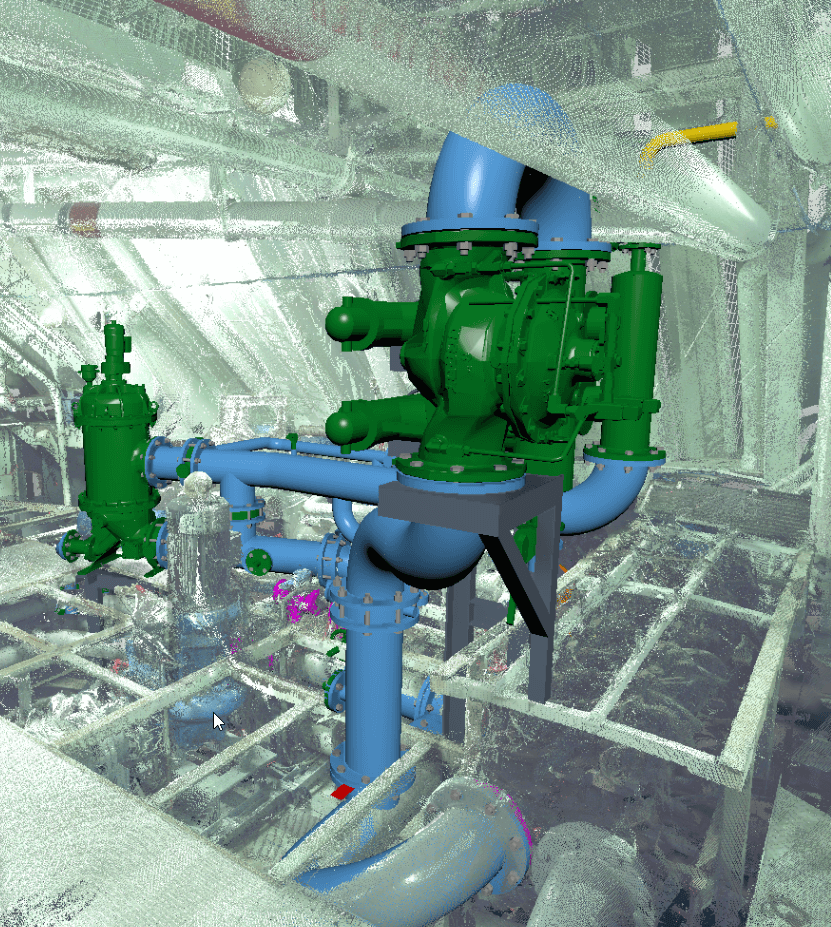

- 3D scanning & vessel survey

- Basic and detailed engineering

- Class approvals

- Procurement & Prefabrication

- Project Management

- System installation and Commissioning

- Installation supervision

EXECUTION:

Goltens completed the 3D scanning onboard in a single day and delivered the baseline concept design to the client 11 days later. Moving quickly to get agreement on the conceptual design, Goltens design engineers delivered the detailed engineering less than 30 days later.

With roughly a month remaining prior to the planned start of the installation, Goltens moved quickly to acquire the necessary materials and prefabricate the pipe spools, brackets, valves and other materials and get them delivered to Norway.

Goltens deployed a Supervisor, an electrician and 3 pipe fitters to the vessel and completed the installation from end to end in only 15 days.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now