Green technologies process applied to drive three system piping renewal

Turnkey installation of piping systems – minimal interruption for seismic vessel

Goltens Oslo was approached by one of the world’s largest geoscience companies to use Goltens as a “one-stop shop” for their diesel engine overhauling and vessel piping system upgrade needs.

Their C-class seismic vessel required 40,000-hour overhauls and main engine cooling and fuel system upgrades along with a new bunkering line.

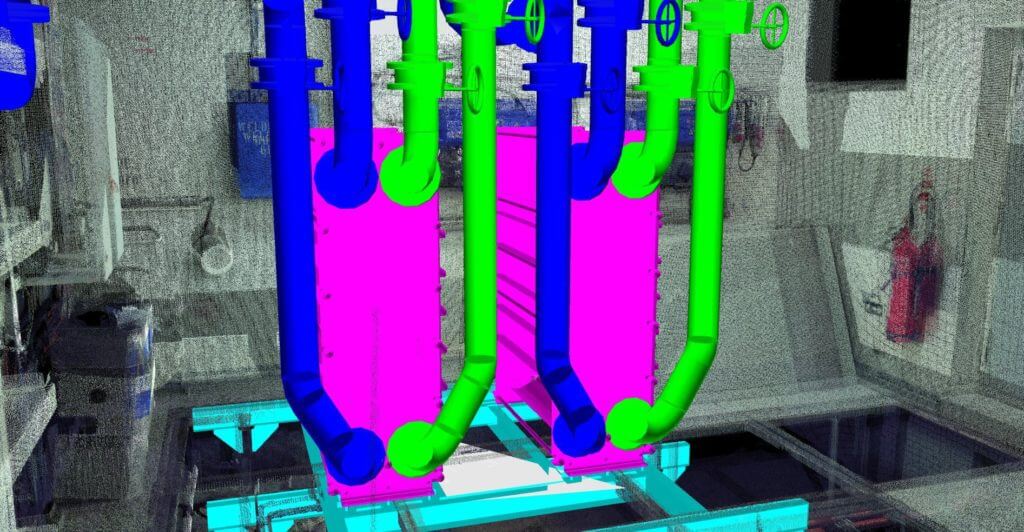

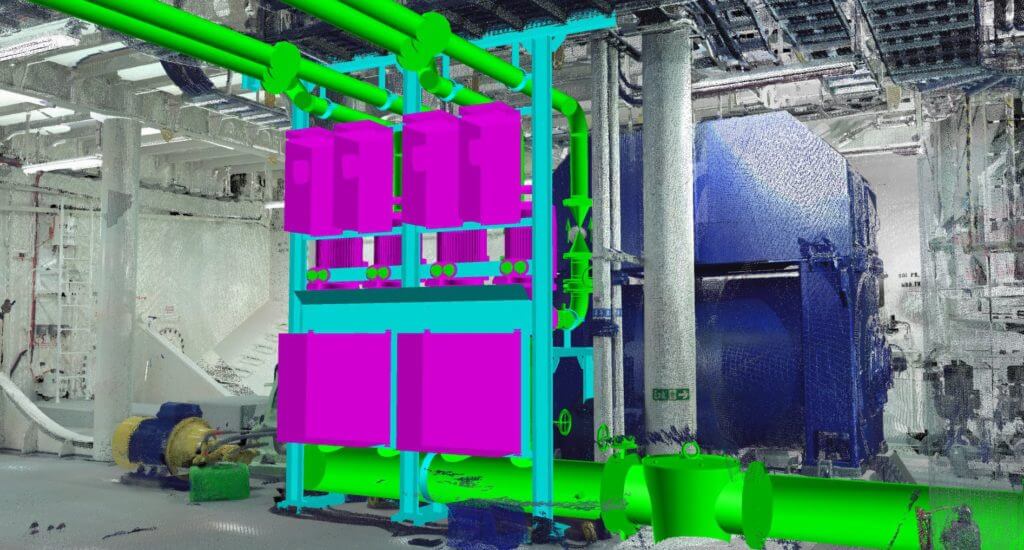

To complete the piping upgrades in the most efficient manner with the absolute minimum amount of asset downtime, Goltens Oslo chose to leverage Goltens Green Technologies’ proven process used for Ballast Water Treatment and Sulfur Emission Control retrofits. The process consists of 3D laser scanning, system modeling, detailed engineering and prefabrication culminating in onboard installation of the systems.

PROJECT FACTS

| PIPING RENEWAL/MAIN ENGINE OVERHAUL | |

|---|---|

| Piping Systems Renewed: | Main Engine Cooling, Fuel System and Bunker Line |

| Main Engine Type: | Bergen B32:40L9P |

| Engines Overhauled: | Four |

PIPING RENEWAL & ENGINE WORK SCOPE:

- 3D laser scanning and modeling of the systems

- Detailed engineering of main engine cooling and fuel system upgrades and new bunkering line

- Pre-fabrication and onboard installation of all piping

- Complete electrical installation (including electrical control cabinets for shaft & engine cooling systems

- Update of all related ship documentation

- Full 40,000 hour overhauls on 4 Bergen B32:40L9P Main engines

- Commissioning and sea trial

PIPING RENEWAL & ENGINE OVERHAUL RESULTS:

The project was completed with most of the installation work at sea with the exception of new overboard and sea chest intake with no operational impact. Based on the success of this project Goltens was approached again for doing the exact same task for a sister vessel.

Also, due to the results of the overhaul work on the four main engines, Goltens is now the preferred partner for the customer’s main engine overhauls.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now