Engine expertise, crankshaft machining and laser alignment restore gas engine to service in Indonesia

Onsite crankshaft and engine block repair Waukesha 12V-AT27GL series

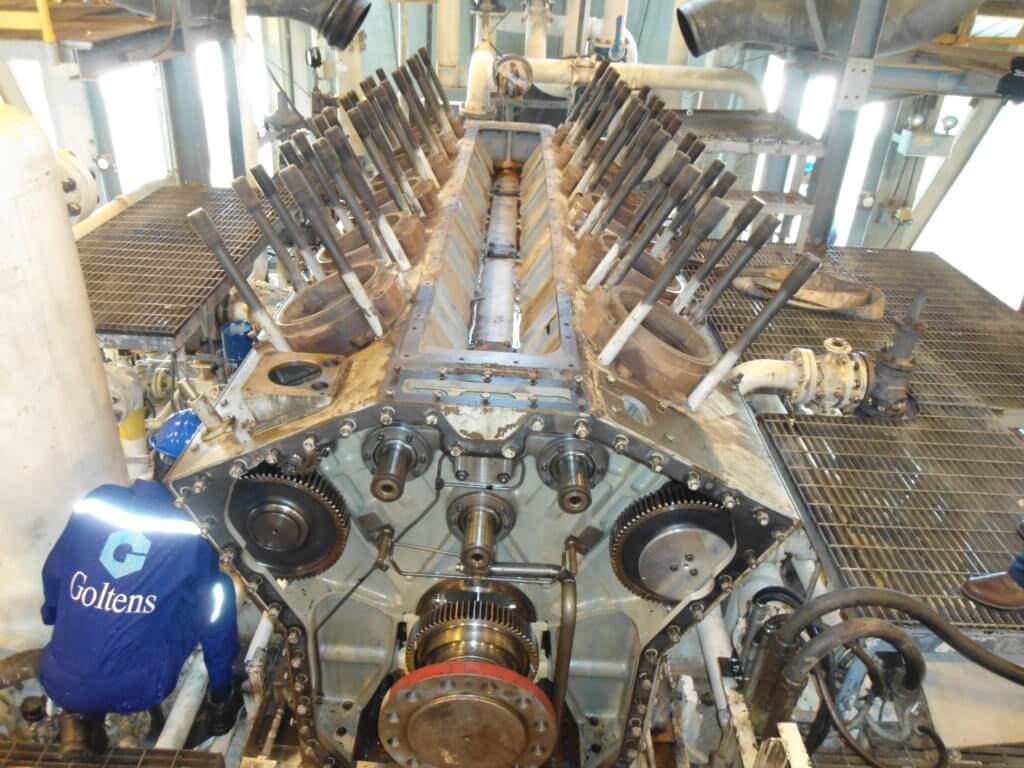

One of the major Oil & Gas companies in Indonesia approached Goltens to inspect and offer the solution for their troubled Waukesha 12V-AT27GL gas engine. A team consisting of a Diesel engineer and on-site machining specialist was sent to site to evaluate the extent of damage and recommend the best repair solution to the customer.

Goltens’ inspection of the engine found damage on one main journal and the corresponding bearing cap and recommended that the crankshaft be removed and machined to undersize to remove the damage. Goltens also recommended that the lower bearing cap be restored utilizing selective electroplating.

Upon customer acceptance of the repair proposal, Goltens quickly dispatched one of its diesel teams to disassemble the engine and complete the required repairs.

PROJECT FACTS

| GAS ENGINE REPAIRS | |

|---|---|

| Engine type: | Waukesha 12V-AT 27 GL |

| Bore/Stroke: | 275/300mm |

| Main Journa dia: | 225.00 mm |

| C/P Journal dia: | 195.00 mm |

| Location: | Jambi – Indonesia |

ONSITE ENGINE AND CRANKSHAFT REPAIRS

- Engine disassembly

- Relocation of engine block to safe area for repairs

- Removal of the crankshaft from engine block

- Check center line of main bearing bore by laser alignment

- Selective electroplating of main bearing pocket no #4 due to corrosion on the mating surface

- Grinding crankshaft main journal no. #4 to -1.0 mm undersize at Goltens’ workshop

- Installation of the repaired crankshaft

- Engine reassembly and laser alignment

- Satisfactory operational testing and commissioning of the engine witnessed by customer

RESULTS

Goltens’ team completed this complicated job within the timeframe agreed by customer complying with the strict HSE requirements of the Oil & Gas industry.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now