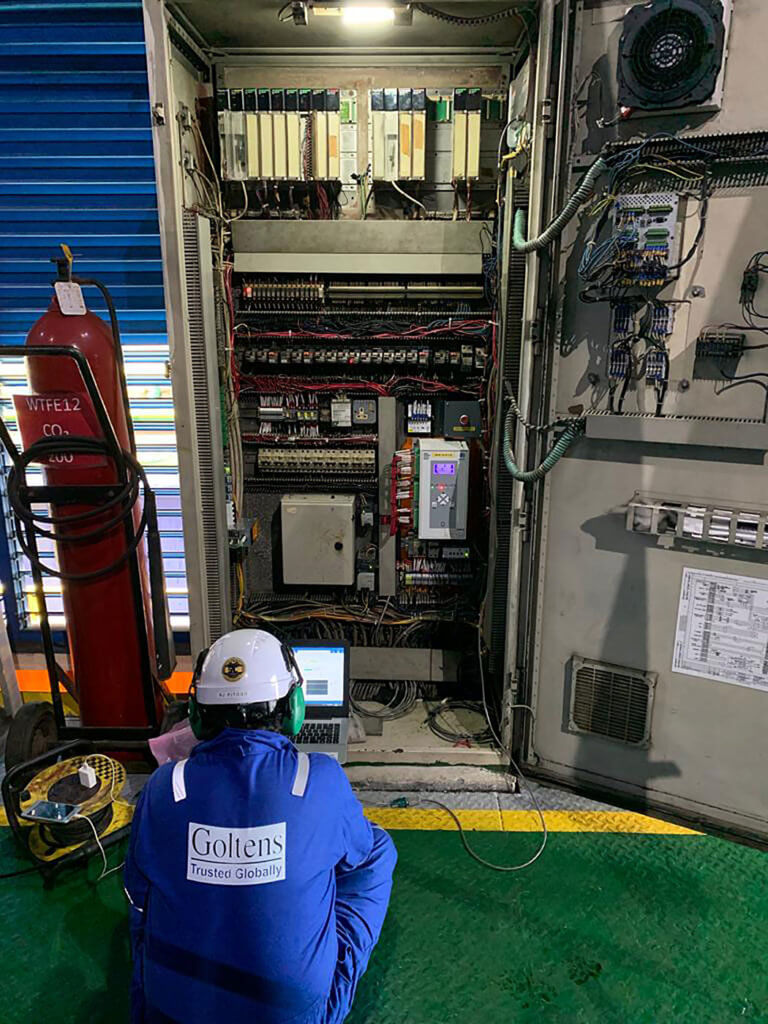

Massive Controls Upgrade Project in Philippines

GOLTENS DELIVERS PERFORMANCE AND EFFICIENCY IMPROVEMENTS FOR 23 WÄRTSILÄ ENGINES

Goltens was engaged to evaluate the current controls configuration on two Therma Mobile inc. Oil-fired floating power barges and propose a solution to both increase the efficiency and reliability of startup and operations while also meeting strict NGCP (National Grid Corporation of the Philippines) regulations for ancillary power load response.

THE CHALLENGE

The company’s barge M3 is equipped with 11 Wärtsilä 18V32 engines while its M5 has six Wärtsilä 18V32 and six 12V32 engines. Both barges had slightly different controls configurations but the issues they faced were the same:

- Engine Hard Start – both barges were experiencing intermittent startup problems where in order for the engines to clear the cranking speed, a barge operator needed to manually assist the actuator fuel linkage. This added significantly to engine startup time and slowed down the barges’ entire synchronization process.

- Simultaneous Synchronization – The existing synchronization relied on a single DEIF synchronizer for each barge controlling the synchronization of all the engines. This resulted in operators only being able to synchronize one engine at a time, dramatically increasing the time to be fully running and synchronized to the grid.

- NGCP Response Requirements – NGCP response targets require that engines must have a Fast Start capability and be able to synchronize to the grid within 15 minutes and load up their offered reserve capacity within an additional 15 minutes. The inefficiencies associated with the existing Engine Hard Start problem and Simultaneous Synchronization challenges made the NGCP time windows difficult to meet. In addition, the NGCP requires frequency deadband and droop functionality, which did not exist in the current configuration.

THE SOLUTIONS

- Engine Hard Start – For the M3, Goltens replaced the existing Woodward PG-EG actuators’ servo valve boosters and introduced preventive maintenance for the connections between actuator and booster. For the M5, Goltens upgraded all 12 legacy Woodward PGG 58 mechanical hydraulic governors with Woodward PG-EG 58 electrohydraulic actuators and Woodward 2301E digital speed controls.

- Simultaneous Synchronization – In addition to the changes made to address the Engine Hard Start issues, Goltens installed Woodward easYgen 3200XT genset controllers on each engine and made modifications to, or disconnected, the existing DEIF synchronizers.

FAST STARTUP, SIMULTANEOUS SYNCHRONIZATION AND NGCP REQUIREMENTS MET

The new controls design, which introduced state-of-the-art Woodward product upgrades to the power barges, and the configuration changes implemented met all of the operating requirements. Engine Hard Start challenges were addressed, and synchronization times dropped from a few minutes to less than 20 seconds. All NGCP time requirements for fast start capability and reserve capacity response were met as well as the requirements for deadband and droop.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now