Liner Diameter Measurement (LDM) on 6RT-FLEX82C

VALIDATION OF LINER WEAR LIMITS AFTER MAIN ENGINE UNIT SUFFERS BLOW BY

The crew of a nine year old container ship, equipped with a Wartsila 6RT-FLEX82C main engine, observed exhaust gas blow by on cylinder #5 during normal operation and could not increase the load above 35%. The cylinder liner had 22,452 running hours and the crew suspected the cylinder liner was excessively worn and needed to be replaced.

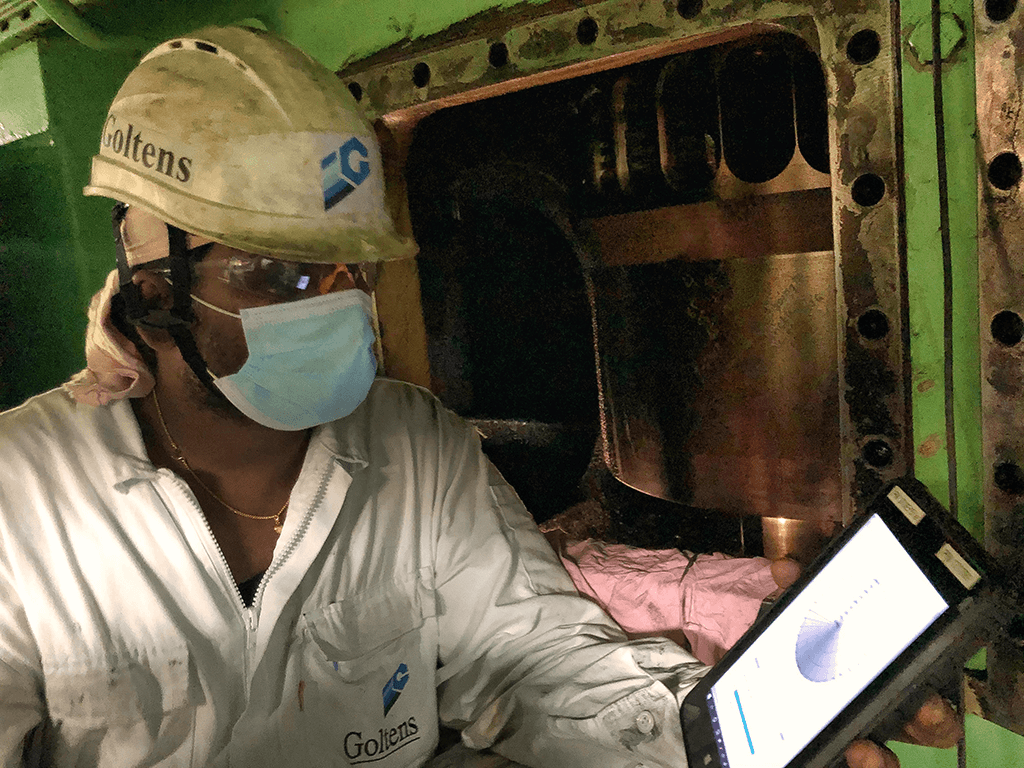

The customer requested Goltens Singapore to attend and replace the liner with an onboard spare and also to evaluate units #2 and #4 which had very similar running hours to unit #5. The vessel was scheduled to enter dry dock in 2021 and the customer wanted to verify the cylinder liner wear and deformation alongside its regular scavenge port inspections.

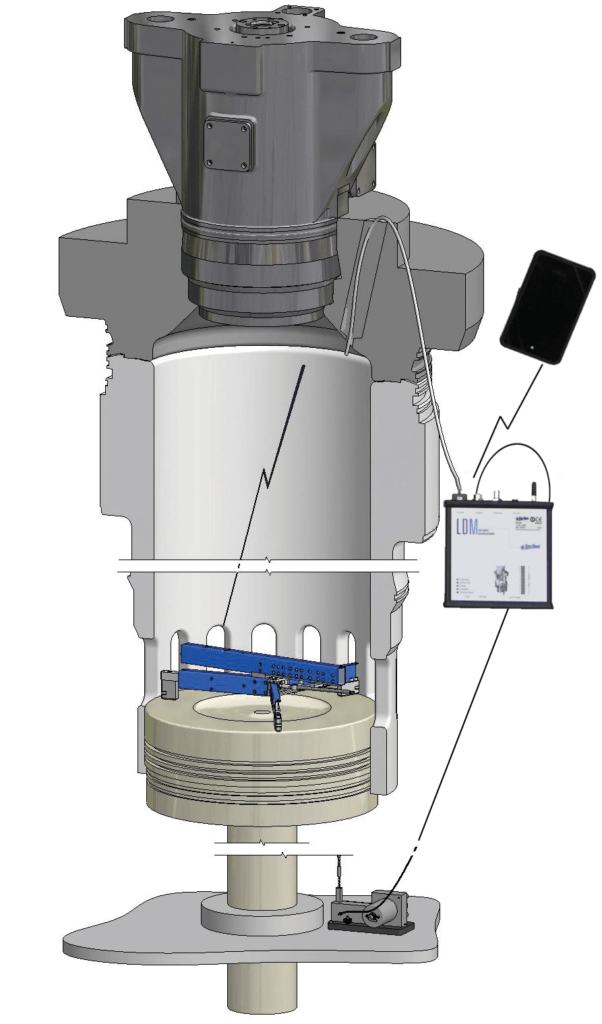

Goltens deployed its technicians with LDM (Liner Diameter Measurement) tooling. The LDM allows for the precise measurement of liners without the traditional labor intensive process of removing cylinder covers and piston assemblies to do a manual measurement. With the LDM, Goltens is able to complete the measurement of an entire 2 stroke engine’s liners in a single day.

LDM INSPECTION PROCESS:

- Lube oil pump stopped and turning gear engaged.

- Cylinder liner temperature confirmed below 70 degrees

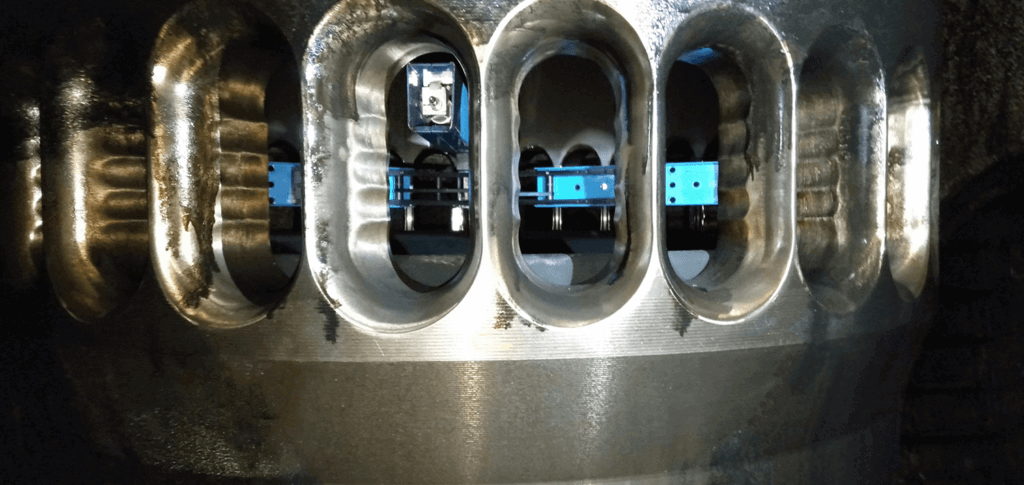

- Scavenge port doors were opened. Scavenge space and piston under side were cleaned.

- Air starting valves removed for LDM Antenna cable insertion.

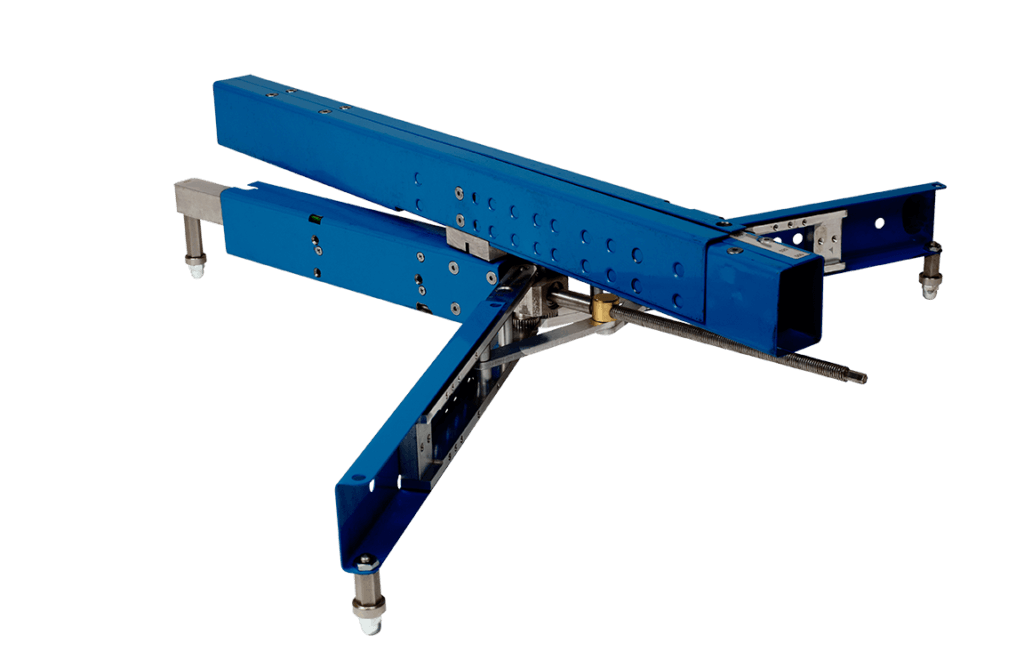

- Measuring arm adjusted according to cylinder liner nominal diameter and measuring arm calibrated.

- Depth gauge attached with piston underside. Antenna communication cable inserted. Measuring arm installed on top of the piston and adjusted to centre.

- Cylinder liner measuring position was programmed. Measuring position taken from maker template.

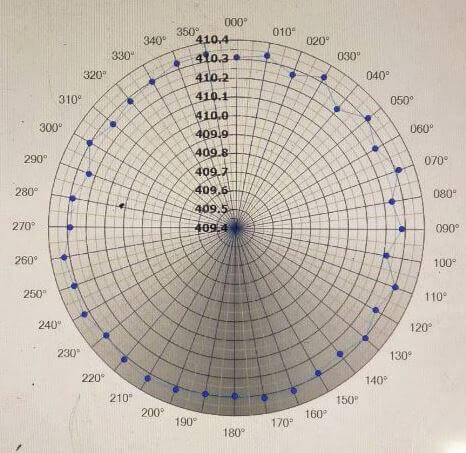

- Cylinder liner wear and clover measurement completed.

- Cylinder liner running surface photos taken using Linercondition camera.

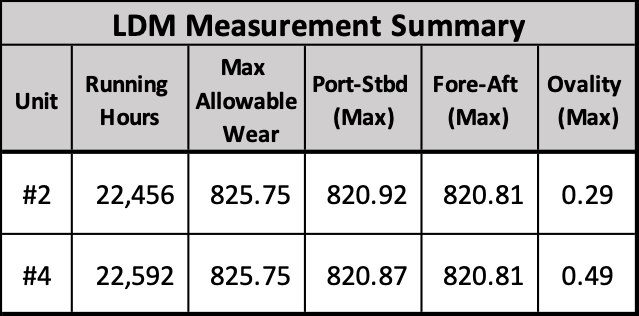

LDM INSPECTION RESULTS:

Unlike unit #5, the cylinder liners in #2 and #4 were found to be in good condition. The maximum cylinder wear level was measured 0.92mm on unit no.2 and 0.87mm on unit no.4. These measurements were well below the maximum allowable wear limits of 5.75mm.

The average liner wear rate on these two liners was found to be quite low at 0.038mm/1,000 hours and .041mm /1,000 hours respectively. Goltens advised that if the current wear rate were sustained that the liner life should exceed 80,000 RHR.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now