In-Situ annealing & machining restore navy fleet replenishment oiler to service in Japan

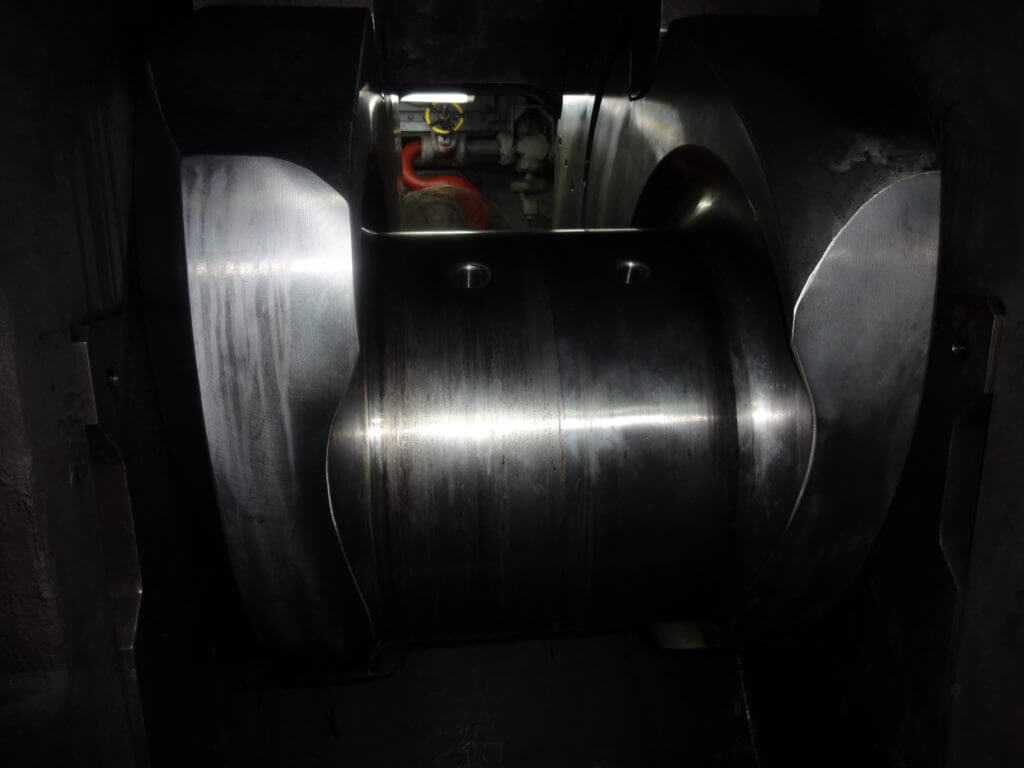

Pielstick 10PC4.2V main engine crankpin

A USNS replenishment oiler experienced a crankpin casualty on one of its Pielstick 10PC4.2V main engines while operating in Japan. The engine maker contacted Goltens to discuss possible in-situ repairs to the crankpin.

The maker reported that crankpin #5 had surface damage and higher than acceptable hardness levels. Goltens proposed the application of its Germanischer Lloyd approved annealing (heat treatment) process in combination with its single point cutting tools to repair the crankshaft and save it with the least amount of shaft diameter loss.

After reviewing the proposed process with Goltens, the engine manufacturer directed Goltens to deploy its in-situ machining and annealing technicians and equipment to Japan to complete the on-site inspection and perform the repairs.

PROJECT FACTS

| PIELSTICK 10PC 4.2V | |

|---|---|

| Vessel type: | Fleet Replenishment Oiler |

| Orig. Crankpin Diameter: | 465.00mm |

| Material Removed: | 2.00mm |

| Post Annealing Hardness: | <300 Hb |

PIELSTICK ANNEALING AND MACHINING PERFORMED

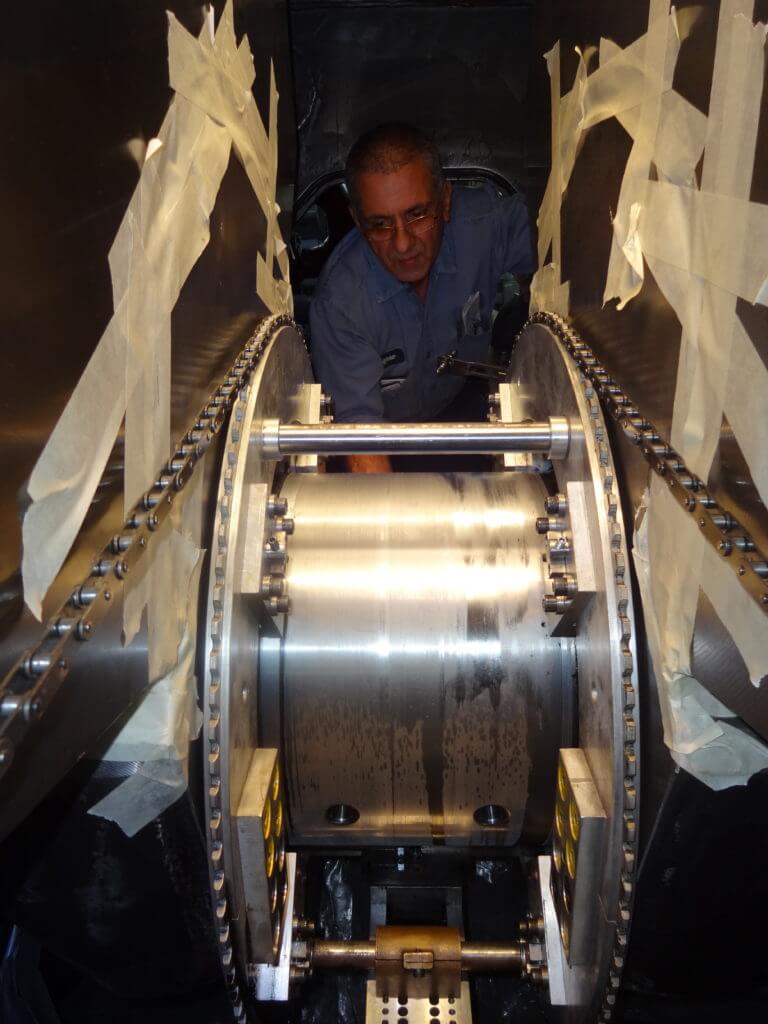

- Inspected the crankshaft – performing run-out, Magnaflux and hardness checks on the shaft

- Pre-annealing machining to -1.30mm to diameter 463.70mm to clear the crankpin of surface cracks

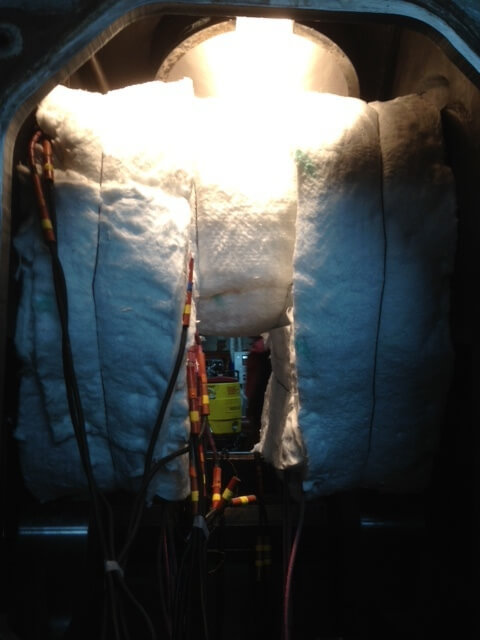

- Annealing of crankpin journal #5 with resulting hardness <300Hb.

- Final machining to -2.00mm undersize

- Machine polished the crankpin to a surface roughness of 0.4Ra

- Completed post–machining run-out and crack tests were

RESULTS

The application of Goltens’ annealing process and in-situ machining avoided a costly and time-consuming shaft removal and replacement. Goltens’ In-Situ machinists completed the repairs to within the maker’s specifications with the smallest amount of shaft loss possible. The job was completed without interruption and allowed the engine to be restored to service with limited additional downtime.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now