In-Situ annealing at Mexican paper mill

Wartsila W18V32 crankshaft

After suffering a bearing failure on Crankpin journal #8 of Engine #2, technical management at a Mexican paper mill contacted Goltens to perform and inspection of the damaged Wartsila W18V32 engine and propose a repair.

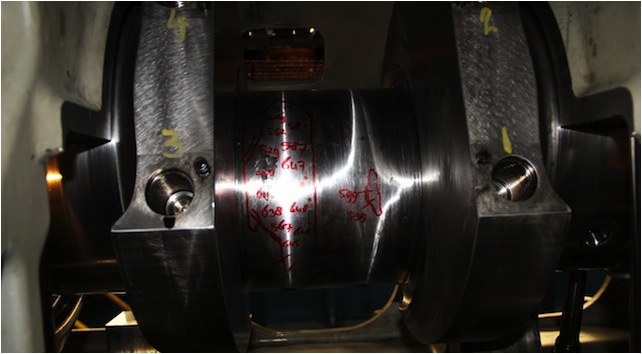

Inspection of the damaged journal revealed hardness values far in excess of the normal hardness for this type of crankshaft with the hardest areas showing hardness values of almost 650HB.

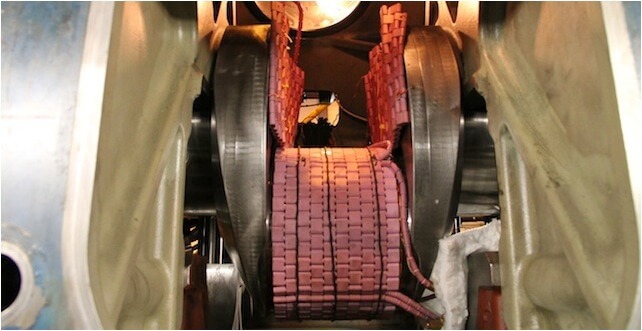

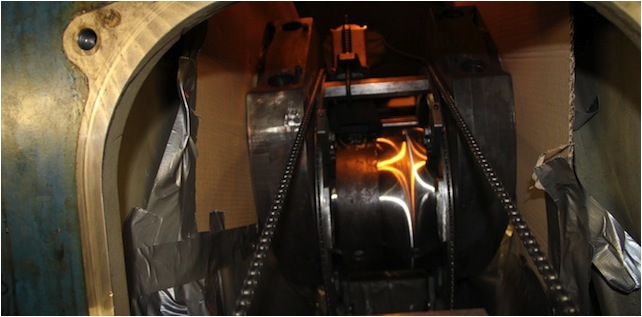

Goltens proposed to machine the crankpin down to a clean surface that was clear of cracks and further evaluate the options. At 308.50mm (-1.50mm), the surface was clear of cracks but the high hardness remained and covered a significant portion of the pin’s surface. Goltens proposed applying its annealing process to reduce the hardness in the crankpin to within specification and retain the largest possible diameter on the crankshaft.

PROJECT FACTS

| Mexican Paper Mill | |

|---|---|

| Engine Make: | Wartsila W18V32 |

| Engine Output: | 6,746 kW at 720 RPM |

| Crankpin Diameter (Original): | 310.00 mm |

| Crankpin Diameter (Finished): | 307.00mm |

| Max Hardness pre-Annealing: | 650HB |

REPAIRS

- Removed 1.50 mm from crankshaft prior to annealing

- Annealed the damaged crankpin to reduce hardness to acceptable levels.

- Machined new fillet radii

- Removed an additional 1.5mm from crankshaft post annealing to finished size of 307.00mm (-3.0).

- Superpolished crankpin journal to acceptable roughness limits

RESULTS

Goltens restored the Wartsila crankshaft with only 3.00mm off the diameter of the crankshaft. Attempts to remove the high hardness purely through machining, if successful, would have dramatically reduced the remaining diameter on the shaft and resulted in significantly more downtime and cost for the owner. With the annealing and finish machining completed, the generator was rebuilt, operationally tested and restored to operation.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now