ENGINE POWER LIMITATION (EPL) INSTALLATION FOR BULK CARRIER

EEXI COMPLIANCE PROJECT COMPLETED IN SHIPYARD IN CHINA

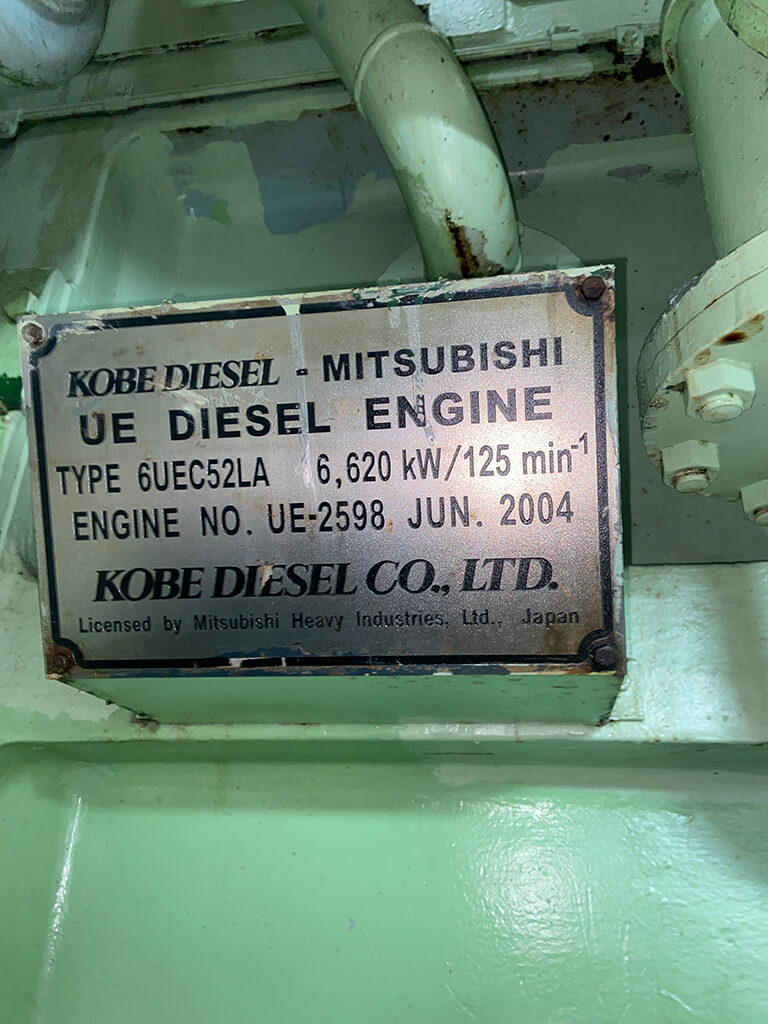

Knowing Goltens’ capabilities to provide comprehensive Energy Efficiency Existing Ship Index (EEXI) compliance packages and support solutions, the owners of a 32,564 DWT Bulk Carrier engaged Goltens to carry out Engine Power Limitation (EPL) work on their UE 6UEC52LA main engine while docking in Long Shan shipyard, China.

Goltens successfully completed the modification work onboard in accordance with the approved EPL and OMM (Onboard Management Manual) documentation.

INSTALLATION PROCESS

- Collect and study the EPL and OMM document, prepare drill tools and seal material.

- Visit vessel in shipyard, meeting with Chief Engineer and Surveyor to discuss EPL installation procedure.

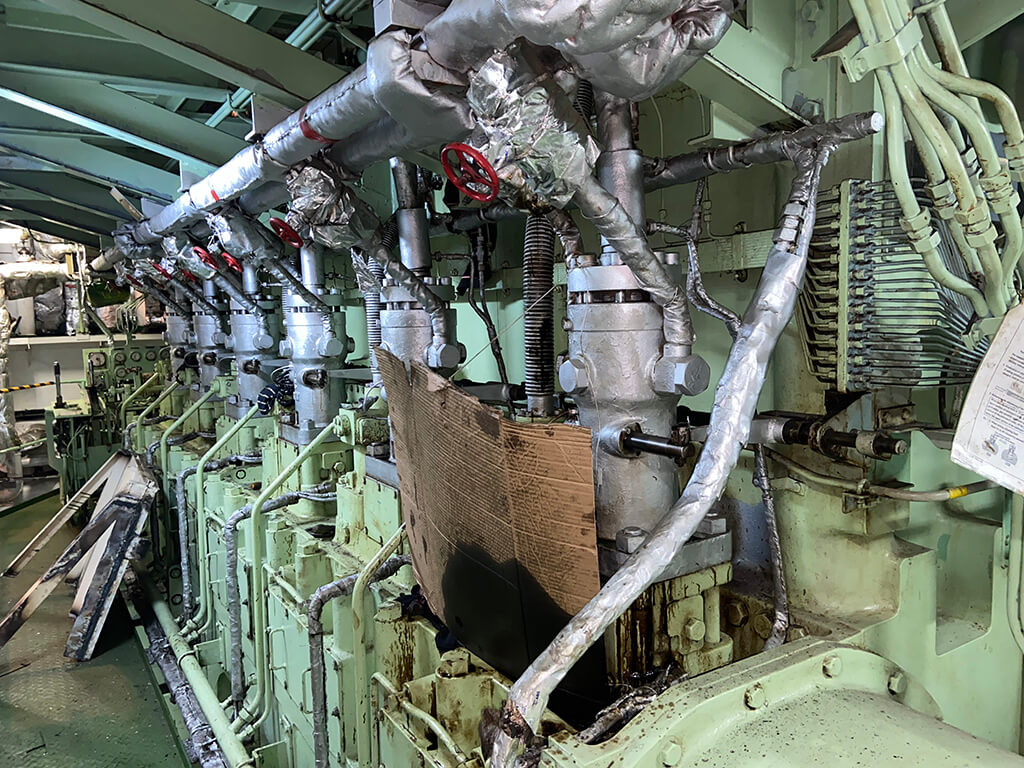

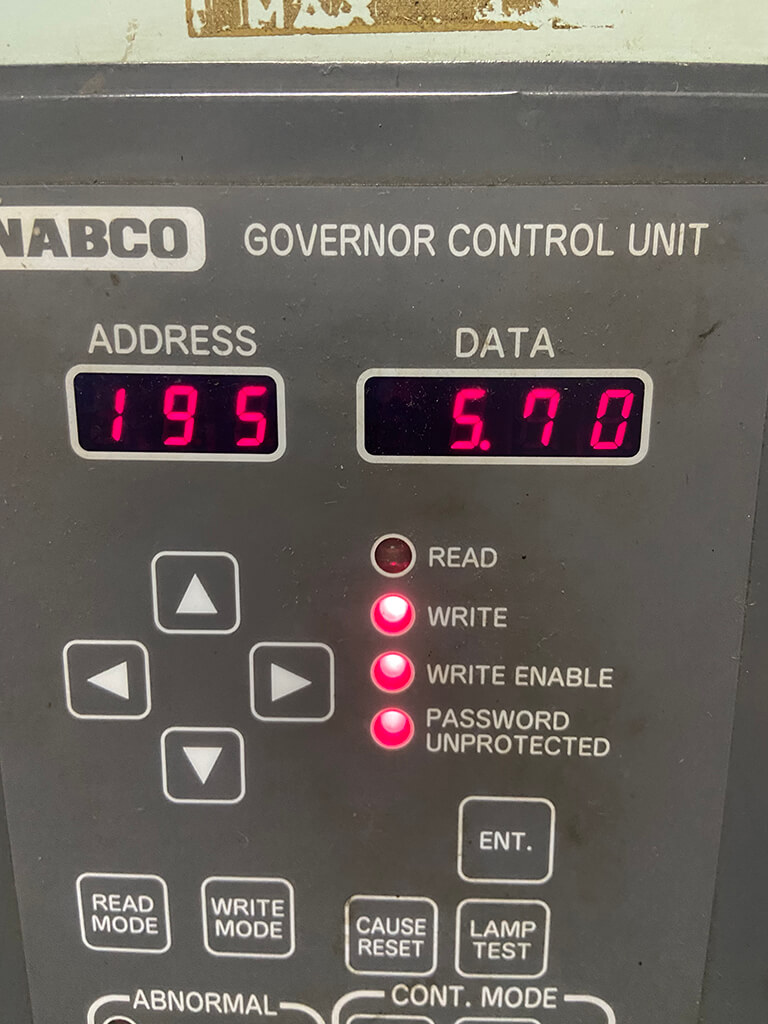

- Disable Main Engine fuel pump control, check the governor original MAX limit data, record all fuel pump and the actuator condition.

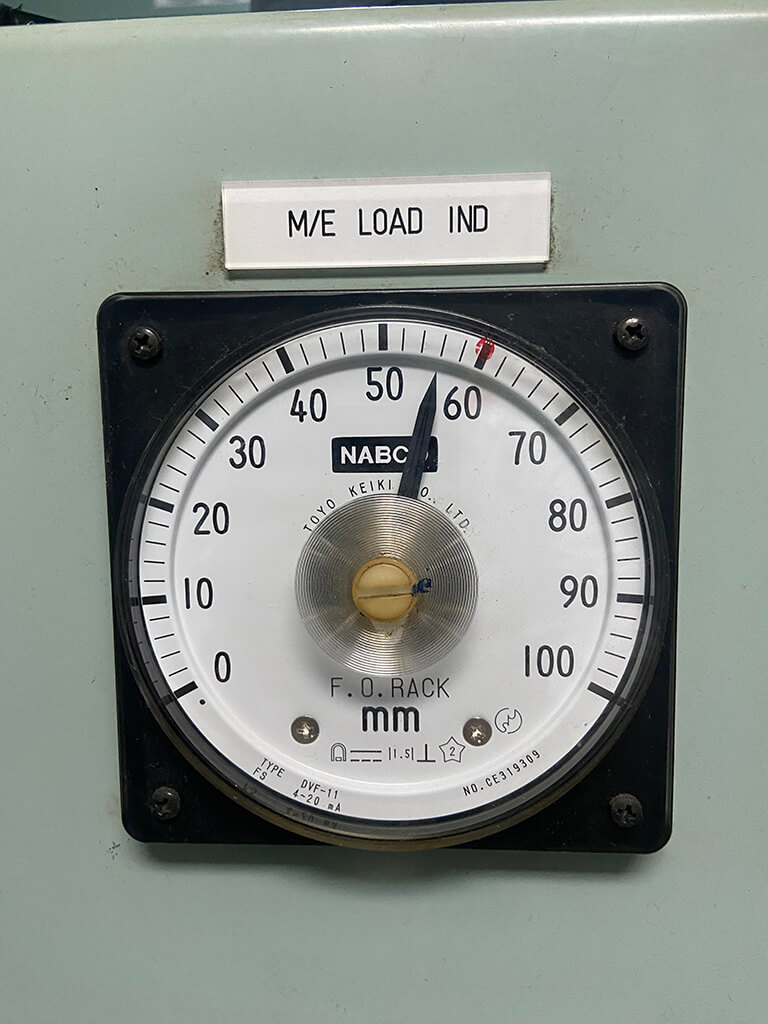

- Enable Main Engine fuel pump control, simulate governor output of new EPL data to system, confirm the Main Engine load gauge position, EAR actuator and fuel oil pumps rack corresponding position is correct.

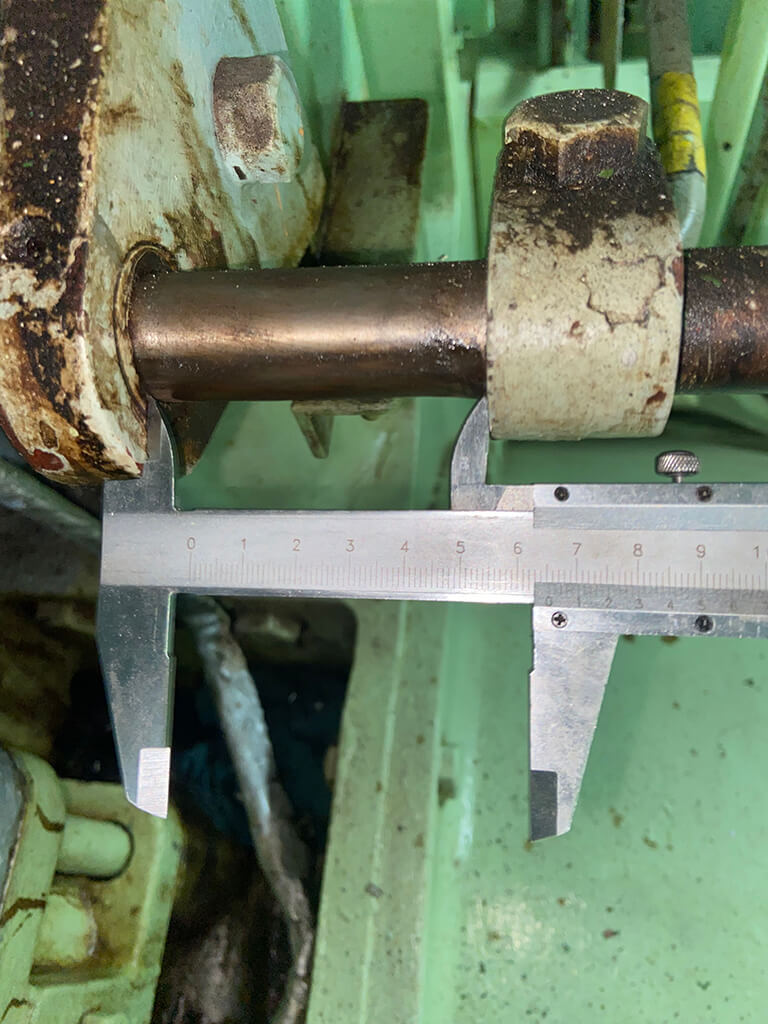

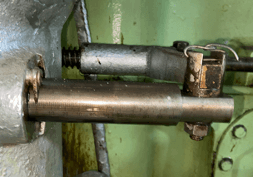

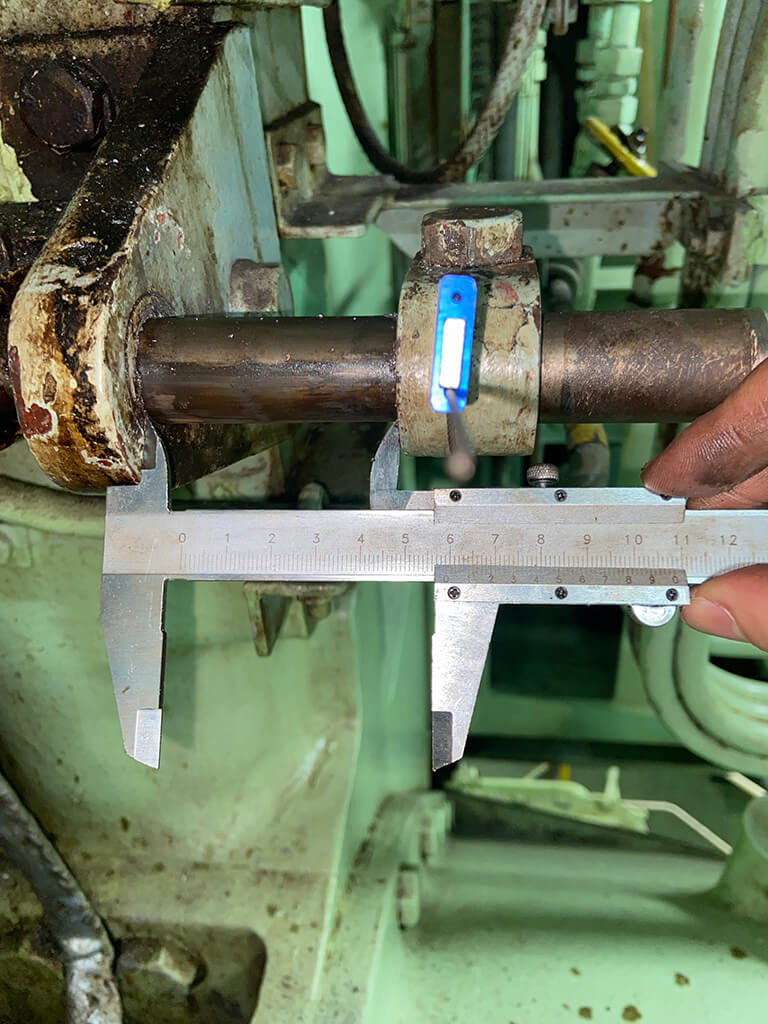

- Hold the simulated EPL setting, drill hole and install locking seal on the mechanical stopper as the key EPL installation step.

- Measure the locked mechanical stopper real length again after re-setting the governor data return to zero.

RESULTS

The successful EPL installation was completed within a single day onboard and witnessed by site Class Surveyor and ship’s crew. Goltens technicians provided an overview of the installation and trained the crew on how the EPL could be restored to the original settings in the event of an emergency.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now