In-Situ machining cruise ship crankshaft after major casualty

Restoration of Sulzer 8 ZAL 40S crankshaft

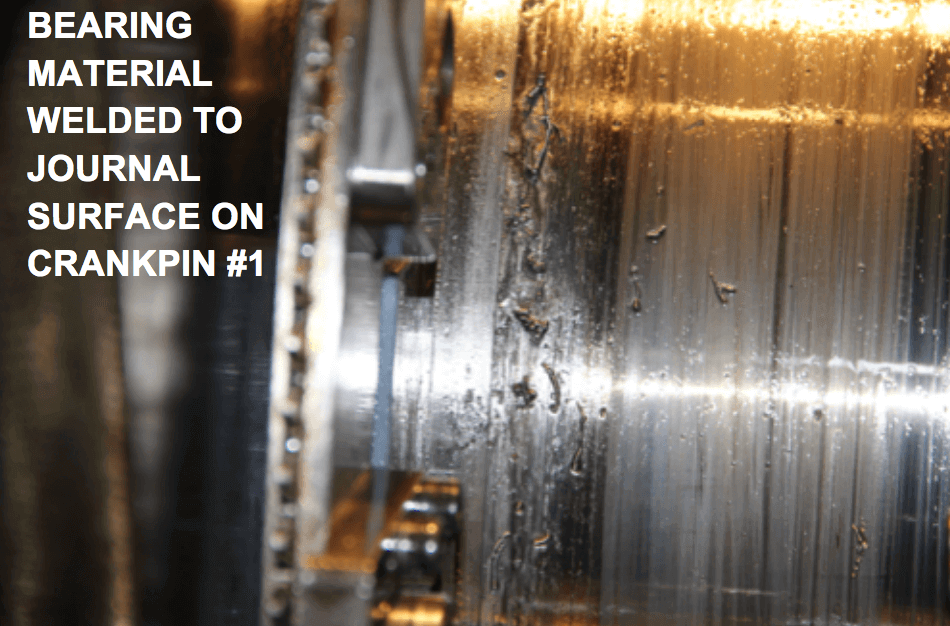

A Sulzer 8ZAL 40S Diesel engine aboard a cruise vessel suffered severe mechanical damage during an engine overspeed resulting in a broken counterweight stud, and severe damage to crankpin #3 and damage to crankpin #1 as well as major damage to the block.

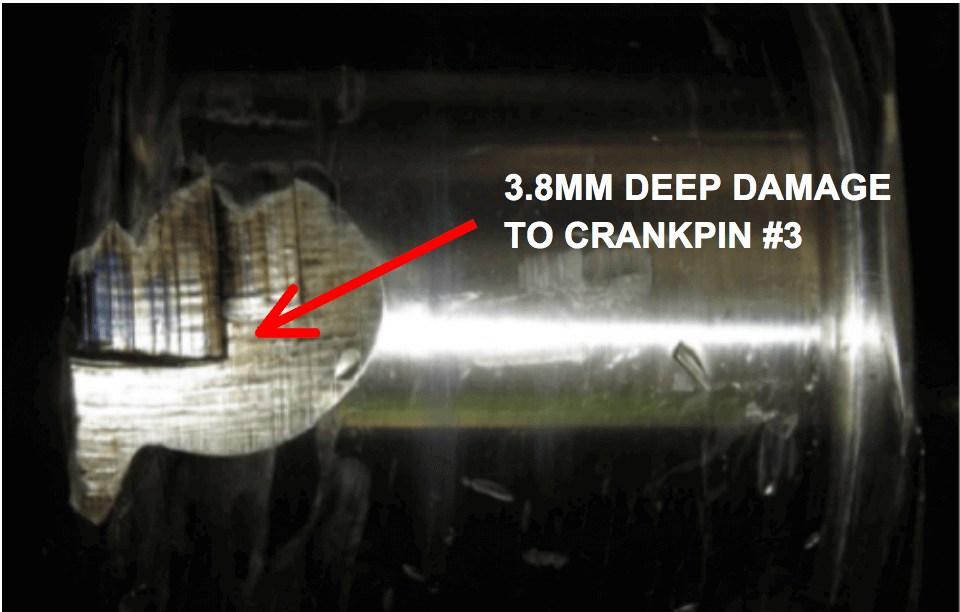

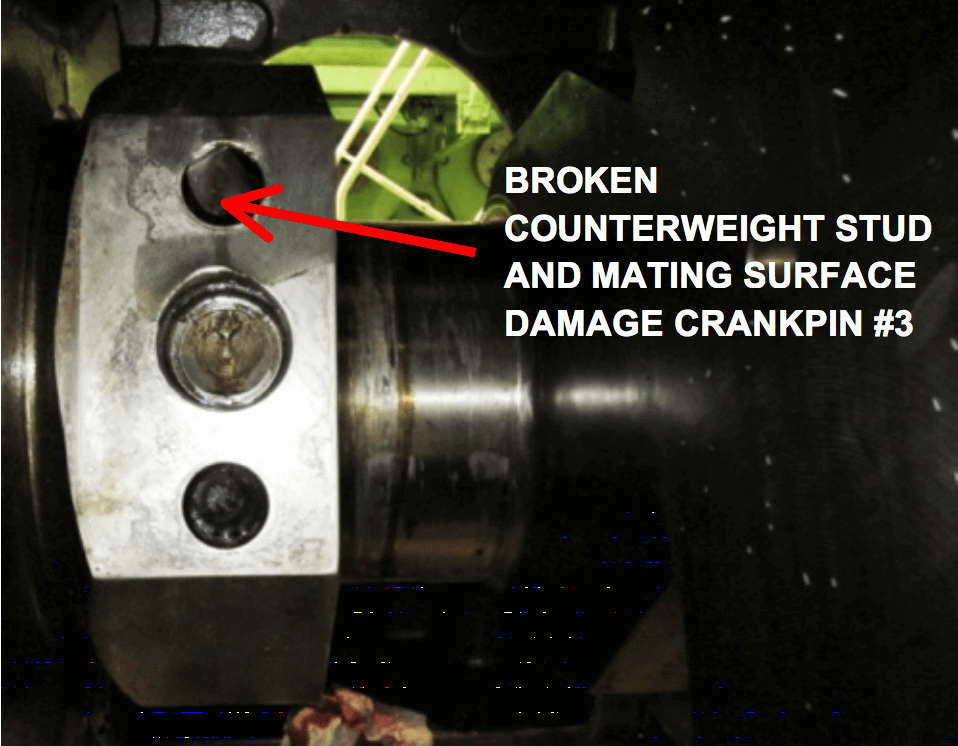

Inspection revealed that the damage on journal #3 went all around the circumference of the journal #3 with severe damage to the radius and deepest damage measured at 3.8mm depth. Additionally, Goltens found a sheared counterweight stud and damaged mating surface for the counterweights.

Goltens met with the customer’s management and consultant and agreed upon a crankpin damage repair protocol to rectify the severe damage within manufacturer’s limits of 340.00mm journal diameter.

PROJECT FACTS

| Sulzer 8 ZAL 40S | |

|---|---|

| Engine Output: | 5760kW |

| RPM: | 514 RPM |

| Original Crankpin Diameter: | 350.00 mm |

| Distance between Webs: | 180.00mm |

| Finished Crankpin Diameter CP3: | 342.00 mm |

| Finished Crankpin Diameter CP1: | 347.00 mm |

SULZER 8ZAL 40S REPAIRS

- Machined new fillet radii on Crankpin #3 due to extensive damage to create clean reference surface.

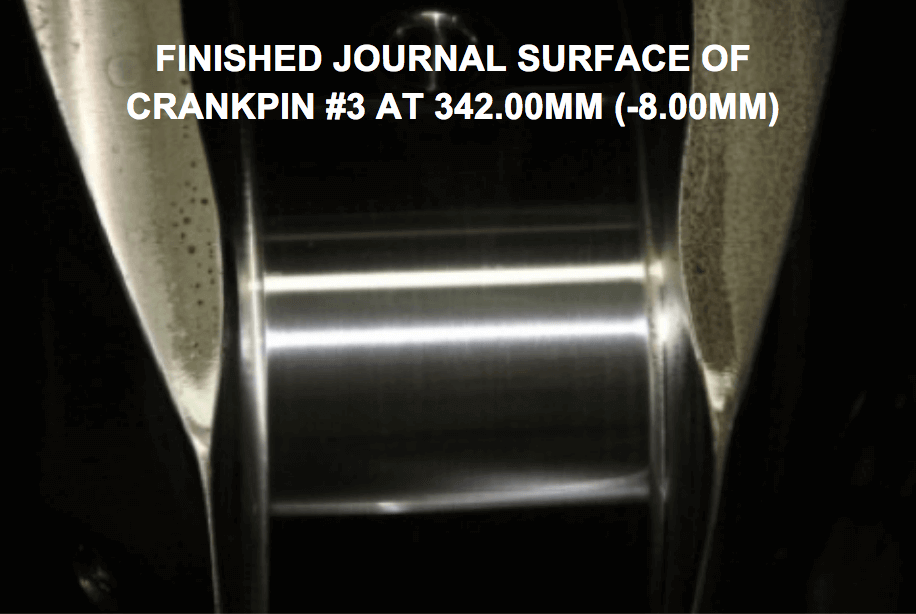

- Machined -8.0 mm off the diameter of Crankpin #3 to finished diameter 342.00 mm

- Machined -3.0 mm off the diameter Crankpin #1 to finished diameter of 347.00 mm

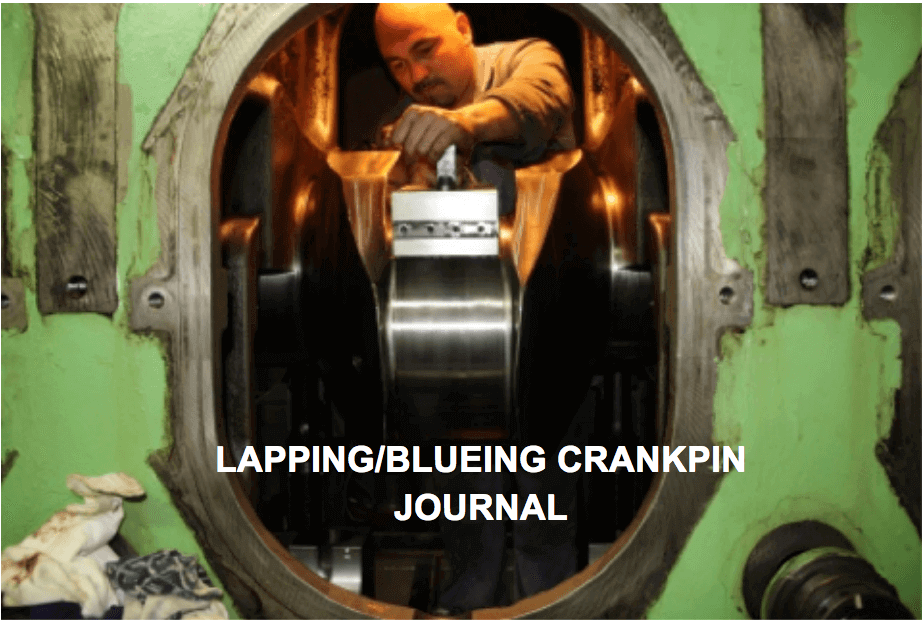

- Lapped and blue fit journals with custom machined aluminum dummies and established a surface contact area and roughness (<0.4Ra)

- Final measurements found to be within Maker’s specification including:

- Hardness check

- Crack test via Magnaflux

- Full calibration of crankpin dimensions

- Run-out Measurements

- Machine polished crankpins #2, #4, #5, #6, #7, #8

- Lapped and blued all above mentioned crankpins to achieve desired surface contact area as per engine maker specifications while maintaining within the standard size diameters as given by the engine maker.

COUNTERWEIGHT LANDING SURFACE REPAIRS CRANKPIN #3 CONSISTED OF:

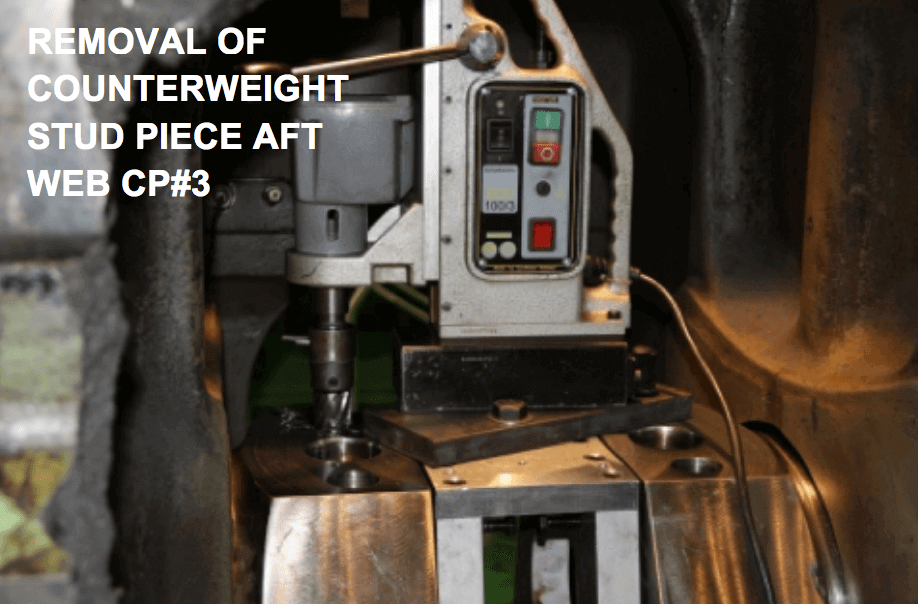

- Drilled out broken counterweight stud located on AFT crankpin #3 web

- Threads on all counterweight mounting holes were inspected and threads cleaned to operational status

- Fabricated custom journal mounted bracket for in-situ tooling and machined forward and aft counterweight surfaces to -0.80mm

SULZER CRANKPIN REPAIR RESULTS

Goltens’ in-situ technicians salvaged the crankshaft within the rated diameter limits and restored the crankshaft to full service at rated horsepower. Performing the repairs in-situ avoided a costly disassembly and transport of the shaft to a workshop and saved avoided significant downtime for the engine.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now