BWT retrofit install on a platform supply vessel

3D scanning, design, fabrication and installation during normal operation

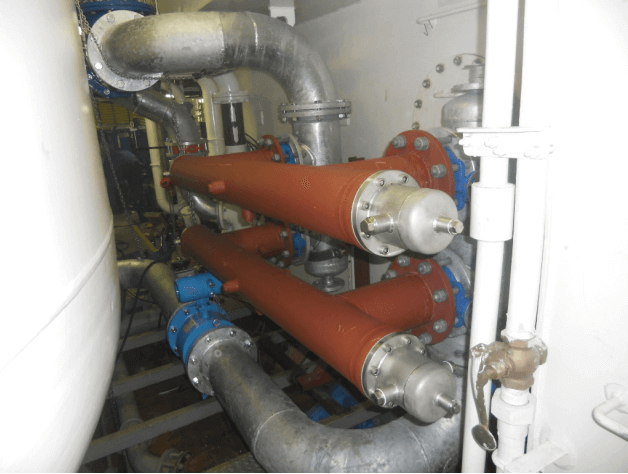

Gulf Offshore NS Ltd., the owner of the platform supply vessel Highland Prince, contracted Goltens for turnkey installation of an Optimarin ballast water treatment system. This treatment system is based on UV technology and consists of a ballast water filter that filters the water on intake, followed by treatment with UV radiation to effectively kill any remaining live organisms that passed through the filter

Avoidance of downtime was critical to the owners so Goltens executed a plan that would enable the vessel to stay in operation and complete the installation in a highly efficient manner.

To accomplish this, Goltens performed a highly accurate (±2.00mm) 3D laser scan of the space and checked relevant technical details for electrical connections and available passage for rigging the equipment onboard. The 3D scan was used to generate a 3D CAD design of the installation and detailed engineering drawings were made, after which, all parts were prefabricated to a very high precision.

Goltens delivered the piping and equipment onboard and a Goltens riding crew joined the vessel to complete the installation of the prefabricated piping and Optimarin system.

BWT RETROFIT PROJECT FACTS

| M/V Highland Prince | |

|---|---|

| Ship Type: | Platform Supply Vessel |

| Weight: | 4,826 DWT |

| Ballast flowrate: | 250 m³/hr |

| Total ballast capacity: | 2,630 m³ |

| Ballast treatment system: | Optimarin OBS 334 m³/hr |

BALLAST WATER TREATMENT RETROFIT PROCESS

- 3D Scanning and Modeling and Detailed engineering

- Prefabrication and installation of new ballast piping and connection to the ballast treatment equipment

- Connecting all electrical parts and cabinets

- Pulling cables for the new electrical connections

- Pressure testing of the system post installation

BWT RETROFIT RESULTS

The process executed by Goltens Green Technologies enabled the installation to be completed while the vessel was in operation with no downtime for the vessel. Onboard installation was completed in only four days by Goltens’ riding crew. CUSTOMER TESTIMONIAL: “We are very pleased with the work that Goltens Green has done for us so far on a number of our vessels. The 3D laser scanning and the detailed engineering has helped to speed up the installation on board and ensured all components are ready for installation in the time frame we have available. On two occasions an experienced Goltens riding squad joined the vessel to install the equipment during normal operation ensuring both vessels had no down-time during installation. This is of course essential, for us and our customers, as we do not want to take the vessel off-hire unless it is absolutely necessary. Two more vessels are in the planning to do in this same way later this year. We have a program for BWT installations throughout our fleet and Goltens Green expertise will be utilized for the installations. In fact they have already prepared 3D scans of our vessels in order to speed future installations”. David Evans Fleet Manager Gulf Offshore NS Ltd

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now