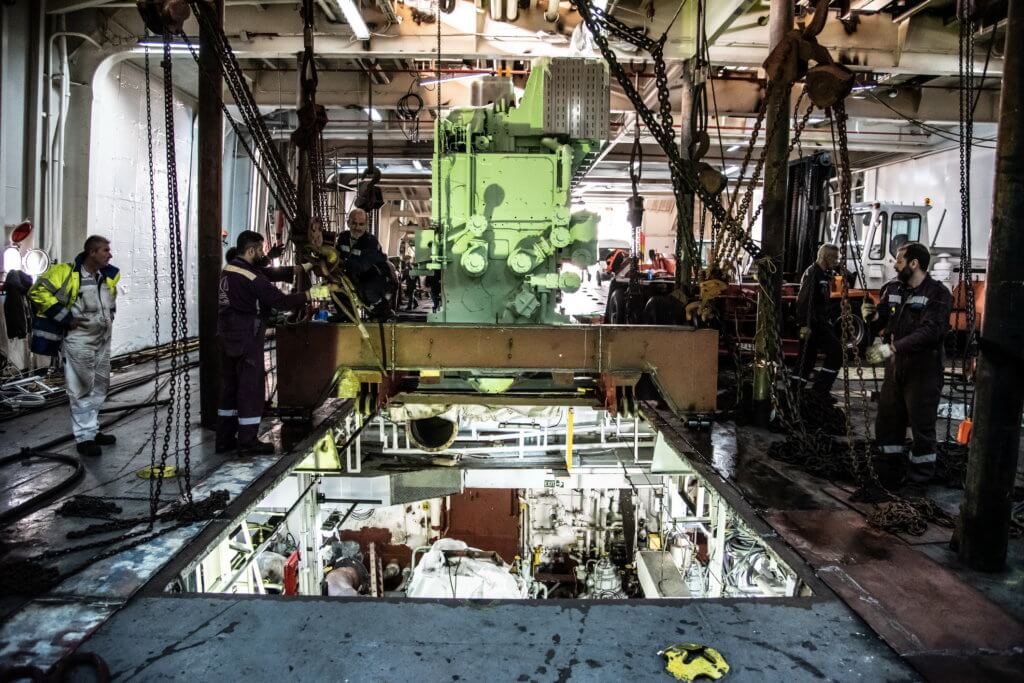

Alignment and installation of two MaK 8M32C engines

PRECISION ENGINE ALIGNMENT FOR FERRY OPERATOR IN GREEK SHIPYARD

A Greek ferry operator made the decision to replace the 30- year-old engines onboard one of its vessels with two new MaK 8M32C diesel main propulsion engines.

The welding preparations and rigging were handled by the shipyard personnel, but the owner sought Goltens’ expertise for proper installation of the engines on the foundations. This included precision alignment of the engines to the gearboxes and chocking of the engines in place.

PROJECT EXECUTION:

Goltens prepared the detailed installation and chocking plan for class submittal and deployed a team to the site. Upon arrival, the port engine had already been lowered into position and Goltens proceeded to weld the jacking plates in place and move the engine to set the correct axial alignment distance for the Vulkan coupling. During this time the starboard engine was lowered into position and work on the engines began in parallel.

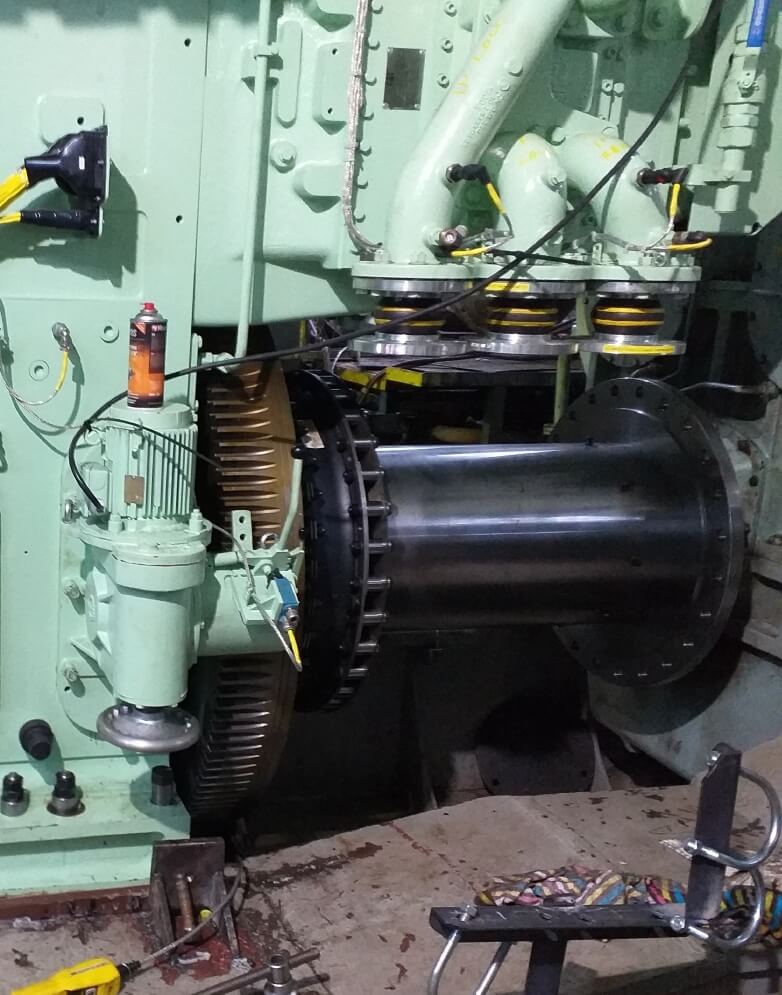

Once Goltens completed the thermal growth calculations, the team performed laser alignment to move the engine into the final position. The team then drilled all foundation bolt and fitted bolt holes and welded the prefabricated collision chock brackets in place. The final alignment checks, including crankshaft deflections, were then taken prior to chocking the engine. The damming material was then installed, and the chocking material was poured.

After curing of the chocking compound, the foundation bolts were installed, the fitted bolt holes were reamed to their final dimension and fitted bolts were final machined and installed. Once all bolts were installed, they were tensioned to spec. and final alignment confirmed. The team finalized the job with the installation of the Vulkan flexible couplings and fitted the collision chock wedges.

RESULTS:

The overall job was successfully completed over a 40-day period by a 2-man team of alignment specialists. The installation was inspected and accepted by the Class.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now