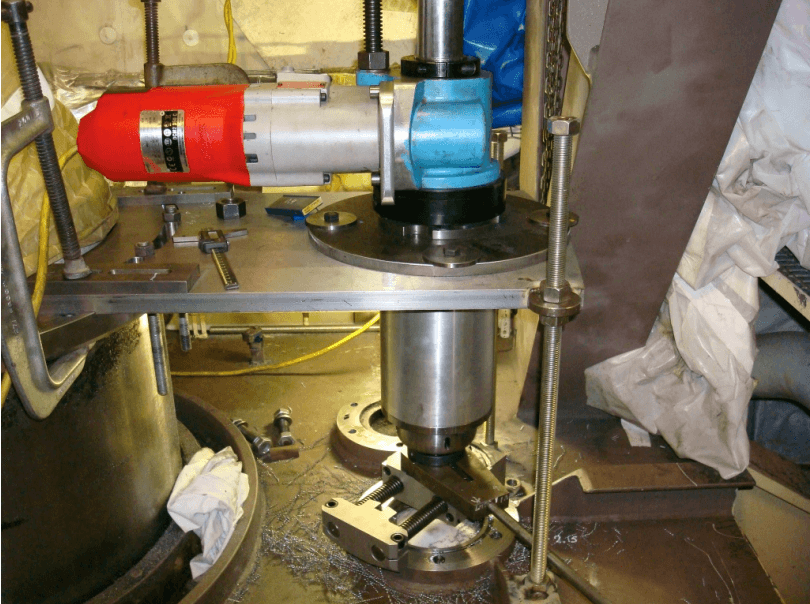

Shipyard flange facing

In-Situ machining on new build naval vessel

Goltens was called in by the manufacturer of an auxiliary propulsion unit being installed on a 142 metre naval frigate being built in a French shipyard.

The propulsion units are retractable and utilize hydraulic cylinders on either side to deploy and retrieve the unit. During construction, the deck plate that the mounting flanges were attached to became deformed/bowed as a result of the welding. The 220.00mm diameter flanges that the hydraulic cylinders and guiding shafts mount to, were significantly out of alignment and needed to be machined true such that they were perfectly perpendicular to the unit’s column.

Goltens arrived onboard to evaluate the extent of the alignment issues and determined after clocking, that the deck-mounted flanges were as much as 2.5mm out of alignment. Having no reference other than the flange for the unit itself, Goltens fabricated a custom steel jig to mount to the flange that provided a true reference over the flanges 500mm away.

PROJECT FACTS

| Vessel Length: | 142 Metres< |

| Vessel Displacement: | 6,000 Tonnes |

| Number of flanges: | 4 |

| Flange Diameter: | 220.00mm |

| Material Machined from face: | 2.5mm max |

| Interior Groove: | 4.8mm x 5.0mm |

REPAIRS

- Alignment inspection

- Fabrication of a machine mounting jig and bearings

- Machining of 4 deck mounted flanges – removing a maximum of 2.5mm from the faces of the flanges

- Renewed interior recess to original 4.8mm depth X 5.0mm wide

RESULTS

All 4 flanges were machined within 2 days to meet the manufacturer’s requirements. Results were inspected and accepted by the equipment manufacturer and installation of the retractable propulsion units continued.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now