In-Situ Machining for Saudi Electric Company Gas Turbine Rotor Shaft

Westinghouse W501D5 Gas Turbine

Saudi Electricity Company (SEC) is a merger of all Saudi electricity companies in the Central, Eastern, Western and Southern Regions into a single joint stock company providing generation, transmission and distribution of safe and reliable electricity services to the customers of the Kingdom of Saudi Arabia.

After experiencing a casualty due to high vibrations on one of its Westinghouse W501DF gas turbines at Asir Power Plant in Abha, Saudi Arabia, SEC approached Goltens to inspect the damage and offer a repair solution. An in-situ repair was required as disassembly and transport of the 37 Ton, 7 meter long shaft would prove costly and add a great deal to unnecessary downtime for the turbine.

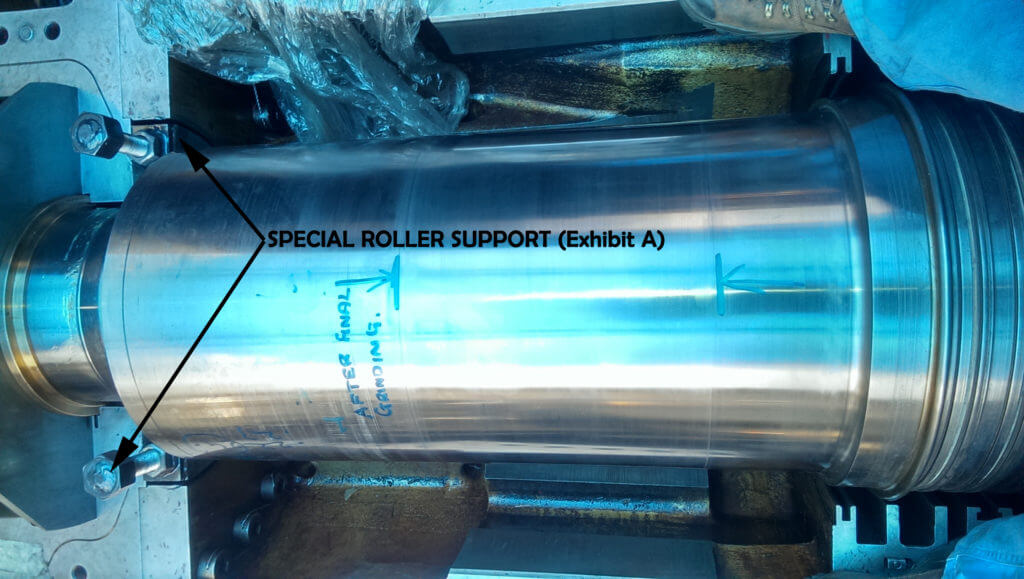

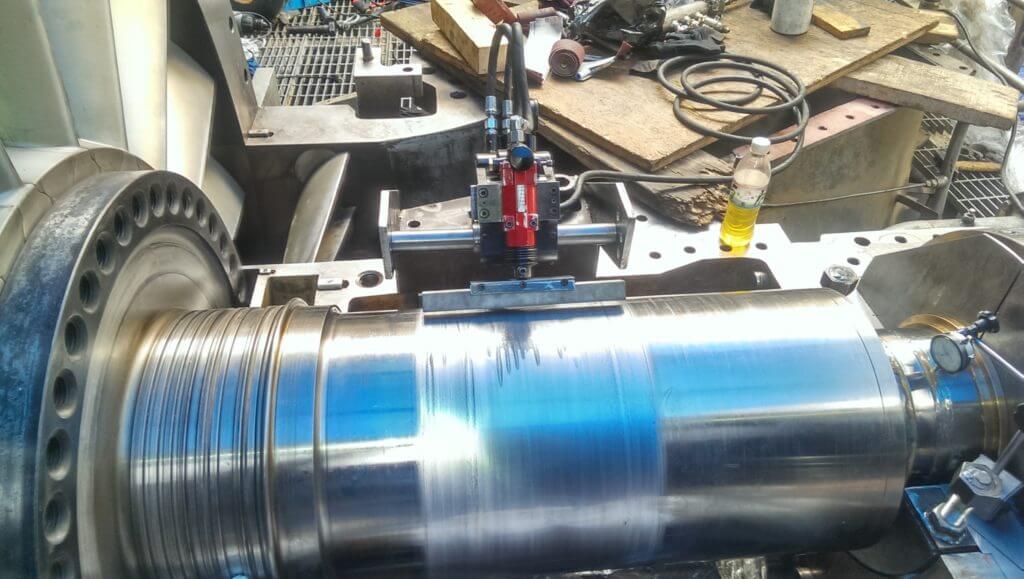

A team consisting of an In-Situ Machining Specialist and In-Situ Technician was dispatched to site to measure the extent of damage and recommend the best repair solution for the compressor side rotor shaft. Inspection, and any eventual machining, would require rotation of the rotor and Goltens fabricated a special roller support to allow for this free movement. Goltens recommended in-situ machining of the damaged rotor shaft journal and mobilized its tooling to complete the repair.

OBSERVATIONS DURING INSPECTION

- Bearing and sealing area observed to have significant surface scoring

- Max hardness levels of 334 HB (some areas could not be measured due to deep scoring marks)

- Magna Flux testing revealed no surface cracks

PROJECT FACTS

| SEC GAS TURBINE | |

|---|---|

| Customer: | Saudi Electricity Company |

| Site: | Asir Power Plant |

| Make/Model: | Westinghouse W501D5 |

| Original Shaft Diameter: | 404.92mm |

| Material removed: | 0.19mm |

| Location: | Abha, Kingdom of Saudi Arabia |

IN-PLACE GAS TURBINE MACHINING SCOPE

- Site Inspection

- Crack Test and Hardness Test

- Preparation/fabrication of special tools

- Fabrication of Special Roller Support

- Grinding up to 0.5 mm

- Machine polishing to required finish

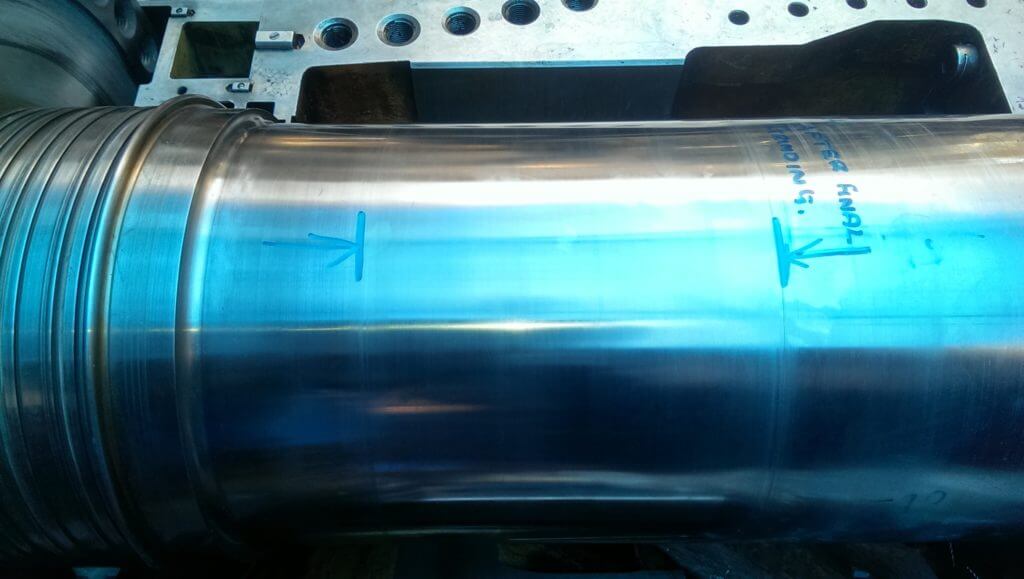

- Crack Test and Hardness Test after final grinding

- Final Inspection

- Blue fit check

IN-PLACE GAS TURBINE MACHINING RESULTS:

After the grinding and polishing, the surface was checked and all scoring was removed and the journal was finished to the required surface roughness with only 0.19mm removed from the shaft diameter. Post machining hardness was measured within acceptable levels between 258HB and 280HB.

Goltens’ team completed this In-Situ machining job within the agreed timeframe and handed over the rotor shaft to Saudi Electricity team for further assembly. Special tooling was fabricated in 2 days and machining was completed in another 2 days on-site.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now