In-Situ crankshaft machining and full engine overhaul for Royal Saudi Navy

King Faisal Naval base, Jeddah

Goltens Saudi received the order from The Royal Saudi Naval Forces (RSNF) to perform a crankshaft inspection for one of its Pielstick 14PC2.5 V400 main engines onboard a French built Boraida class replenishment oiler.

Goltens dispatched an In-Situ Machining Specialist and Mechanical Supervisor to carry out the initial inspection. After the inspection it was found that #4 main journal was damaged due to overheating.

Goltens recommended machining and polishing of #4 main journal to rectify the damage. As a result of the assessment RSNF requested that Goltens complete a full engine overhaul, inclusive of inspection, calibration and polishing of all main and crankpin journals.

After dismantling the engine it was discovered that all of the crankpins had been worn by 0.10-0.12mm below standard diameter. Additionally, it was determined that main journals 1, 2, 3, 5, 7 and 8 all required repair as well. Goltens recommended machining all of the affected journals to the next standard undersize of -0.50mm.

PROJECT FACTS

| PIELSTICK 14PC2.5 V400 | |

|---|---|

| Customer: | Royal Saudi Naval Forces (RSNF) |

| Engine output: | 5,400 kW (13,200 HP) |

| Position: | Port Side Main Engine |

| Type of Repair: | In Situ Crankshaft Machining, Main Bearing Cap Repair & Engine Overhaul |

PIELSTICK 14PC2.5 REPAIR SCOPE:

- Dismantling of the engine

- Inspection and calibration of crankshaft

- In Situ crankshaft repairs:

- Machining all crankpin journals to -0.5mm undersize

- Machining 6 main journals to 314.5mm (-0.5mm undersize) and #4 to 314.0mm (-1.00mm undersize)

- Calibration and overhaul of engine components

- Main Bearing cap repairs

- Reassembly of engine

- Bearing checks

- Engine commissioning and sea trial

PIELSTICK 14PC2.5 MACHINING/OVERHAUL RESULTS

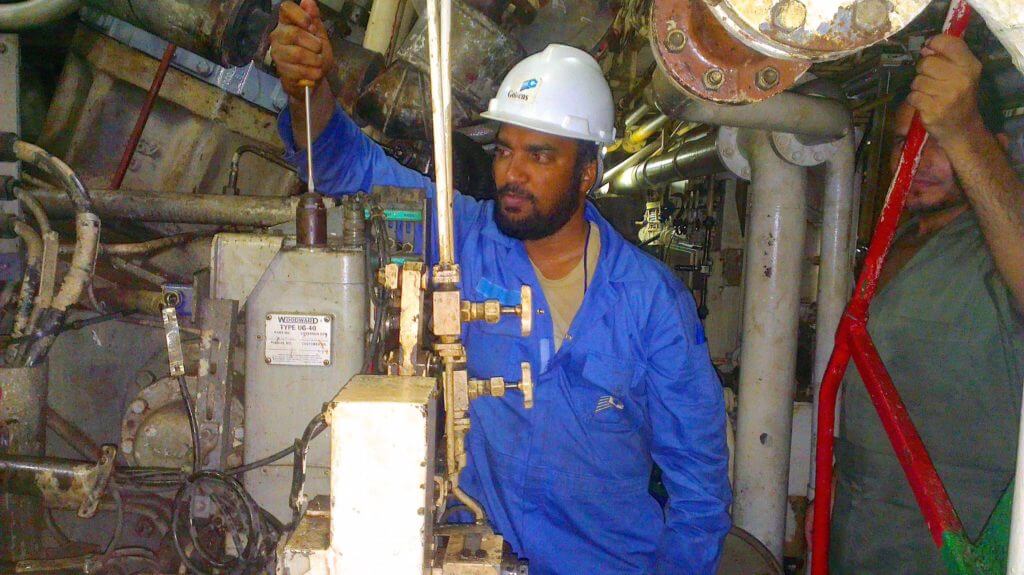

Despite the working environment presenting challenges due to engine room temperature and the tight workspace presented by the engine placement, Goltens completed the expanded work scope within the Navy’s time requirements and to the full satisfaction of RSNF.

Sea trials were completed on June 2, 2015 and the fully repaired and overhauled engine was handed over to RSNF on June 7, 2015.

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now