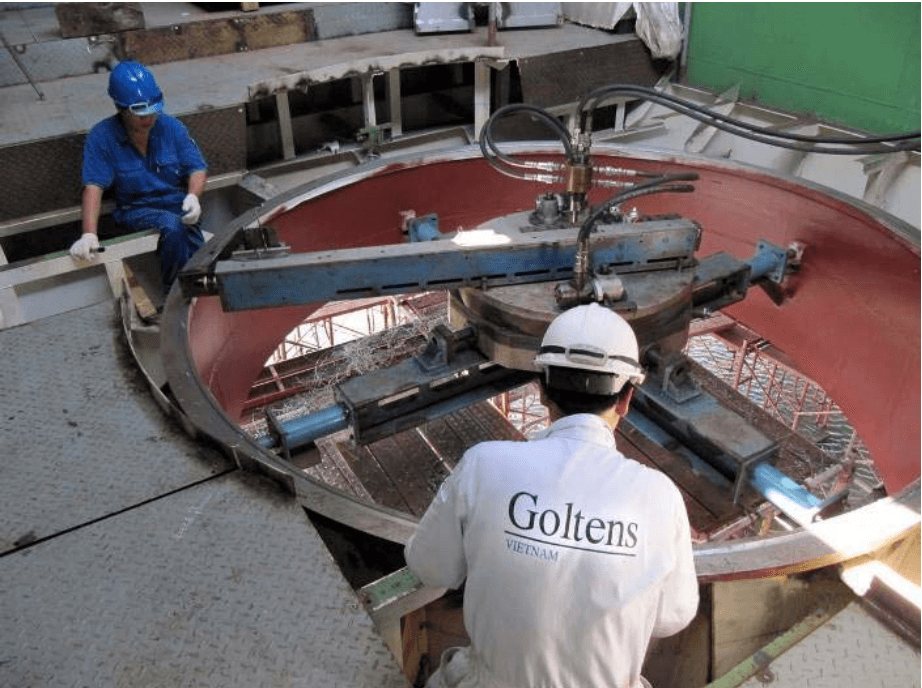

Thruster Flange Facing

Dive Support Vessel Thruster Seats

Goltens recently carried out laser alignment and on-site machining on a diving support vessel for Strategic Marine Shipyard in Vietnam. The job marked the second time in a month that Goltens utilised specialist flange facing equipment in the country.

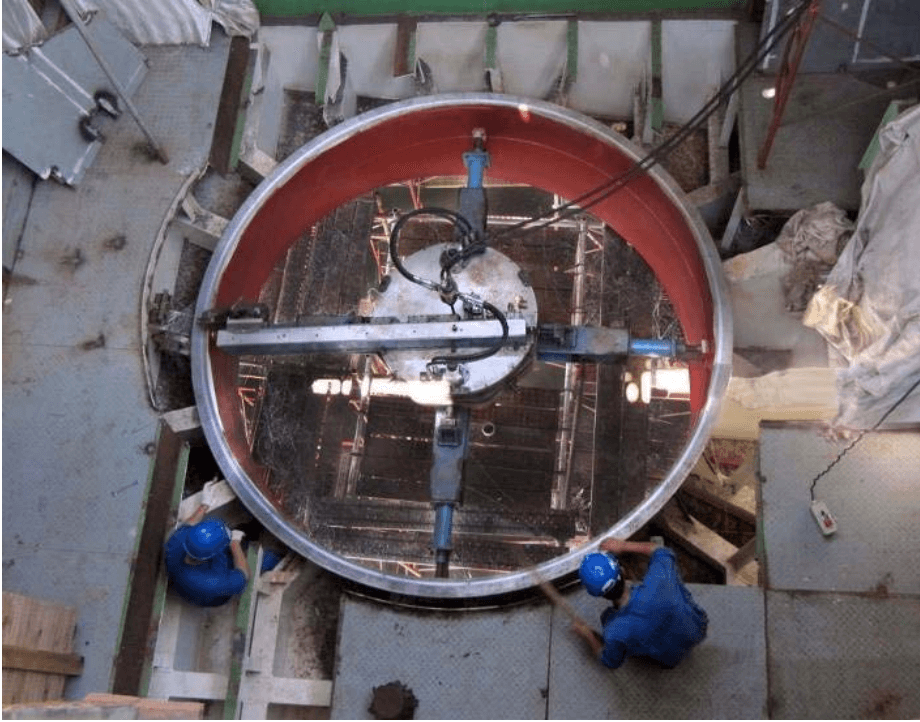

The work on the 145-metre-long vessel involved laser checking the flatness of the entire length of the vessel to determine machining requirements on six thruster seats. After laser check, Goltens successfully carried out machining and PCD drilling of the seats to suit the customer’s tight schedule.

Engaging multiple machines and crews, Goltens worked round the clock for two weeks to complete the job.

With a range of flange facing machines that covers up to six metres in diameter, Goltens are continues to invest in additional equipment to boost capacity and range to meet the continually increasing market demand.

PROJECT FACTS

| 145.4M DIVING SUPPORT VESSEL | ||

|---|---|---|

| Equipment maker: | Roll-Royce | |

| Thruster Model: | Retractable Aquamaster | |

| Foundation diameter (FWD): | 2840mm | |

| Number of surfaces (FWD): | 3 | |

| Foundation diameter (AFT): | 3600mm | |

| Number of surfaces (AFT): | 3 | |

REPAIRS

- Laser alignment of three FWD & three AFT thruster surfaces relativity to each other toward the vessel keel.

- In-situ machining of the surfaces and removing average of 15mm of material from the surface with a tight control height tolerance.

- In-situ machining of O-ring grooves on each thruster surface.

- Marking of the PCD and in-situ drilling of a total of 324 holes per ship set.

RESULTS

Goltens technicians completed this complex job within the maker tolerance requirements with two machines and working round the clock in 14 days

Download a PDF of this Resource

(Right click and select "Save File As..." or "Save Link As..." to save)

Download Now