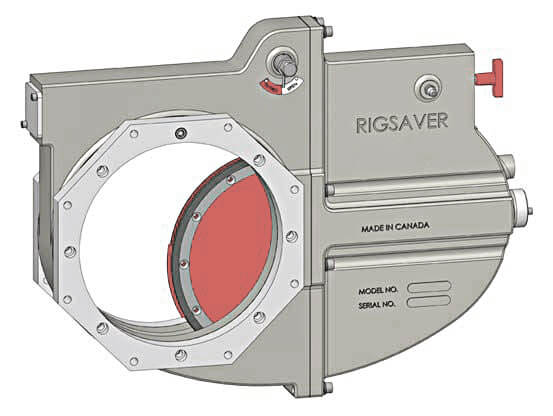

RIGSAVER® Air Shutoff Valve

Goltens is the global sales agent for the Rigsaver® SGE line of air intake shutoff valves.

Rigsaver® valves can be manually or automatically controlled to help prevent diesel engine overspeed by cutting off the air supply to the engine.

Rigsaver® is an ISO 9001:2008 certified swing gate, spring-operated air shutoff device manufactured by AMOT, a world leading manufacturer of overspeed valves, mounted in the air intake system that stops the airflow into the cylinders and positively immobilizes the engine, safeguarding personnel and equipment. It can be manually or automatically controlled, responding to a variety of fault or hazard conditions. They are typically found on engines that operate in environments where there is potential for hydrocarbon vapors to be present in the atmosphere.

The Rigsaver® valve has been used worldwide, providing reliable service on and offshore under adverse conditions associated with locations in the Canadian Arctic, the Gulf of Mexico, the North Sea, the deserts of Africa, the Middle East and the Pacific Rim. The product’s quality meets or exceeds the stringent requirements of our broad customer base, which includes leading engine OEM’s.

For purchase of new or replacement valves, upgrade and maintenance kits or service support, please contact your nearest Goltens location.

Applications

Diesel engines – primarily for offshore power generation. Engine Manufacturers

- CAT

- Wartsila

- EMD

- HHI

- Bergen

- MAN

Rigsaver Features & Benefits

- Manual or automatic controls

- Responds to a variety of fault or hazard conditions

- Available with 2″ (50mm) to 14″ (355mm) of unrestricted port

Rigsaver Upgrade – Next Generation Rigsaver® 11SGE Air Shut-Off Valve

Legacy 11SGE (11 inch) shut off valves (manufactured before January 1, 2014) should be upgraded. After extended periods of vibration, valve may require higher air pressure to activate and regular maintenance schedule was not previously provided. It is recommended the user verify performance with regular cycle testing and adhere to the maintenance schedule contained in this document.

Benefits of upgrading the valve include:

- Higher durability and vibration resistance

- Reduces the required activation pressure to improve reliability

- High quality O-ring seals for better serviceability

- Eliminates charge air leakage

- Larger manual action handle allows user to actuate valve with twist action

- Optimizes components for serviceability

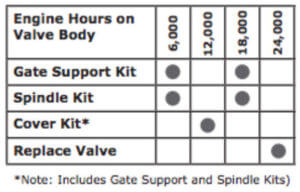

Maintenance Schedule

An important part of optimizing the performance of your RIGSAVER® air shutoff valve is maintaining a regular service schedule. For legacy-style 11” SGE RIGSAVER® valves first upgrade with a Cover Kit to ensure your equipment is protected by the latest design. Next, utilize the Service Schedule to extend the useful life of your valve. For next generation RIGSAVER® 11” SGE valves, it is recommended to replace older parts with genuine RIGSAVER® parts according to the Service Schedule.

Tripping Options

- Manual/Pull-Cable Shutdown – This is the simplest method of activating the valve. The gate is released by pulling on a handle or cable attached to the tip spindle

- Manual/Pneumatic Shutdown – The trip is retracted by an integrated pneumatic cylinder. A manually-operated three-way valve directs air pressure to release the trip spindle. The pneumatic trip cylinder may also be tripped manually by pulling on a handle or cable attached to the trip spindle.

- Manual/Solenoid Shutdown – 12 or 24 volts – The trip spindle is retracted by a solenoid which is controlled by a manually-operated, momentary-contact switch. The solenoid trip cylinder may also be tripped manually by pulling on a handle or cable attached to the tip spindle.

Maintenance Schedule

An important part of optimizing the performance of your RIGSAVER® air shutoff valve is maintaining a regular service schedule. For legacy-style 11” SGE RIGSAVER® valves first upgrade with a Cover Kit to ensure your equipment is protected by the latest design. Next, utilize the Service Schedule to extend the useful life of your valve. For next generation RIGSAVER® 11” SGE valves, it is recommended to replace older parts with genuine RIGSAVER® parts according to the Service Schedule.

Tripping Options

- Manual/Pull-Cable Shutdown – This is the simplest method of activating the valve. The gate is released by pulling on a handle or cable attached to the tip spindle

- Manual/Pneumatic Shutdown – The trip is retracted by an integrated pneumatic cylinder. A manually-operated three-way valve directs air pressure to release the trip spindle. The pneumatic trip cylinder may also be tripped manually by pulling on a handle or cable attached to the trip spindle.

- Manual/Solenoid Shutdown – 12 or 24 volts – The trip spindle is retracted by a solenoid which is controlled by a manually-operated, momentary-contact switch. The solenoid trip cylinder may also be tripped manually by pulling on a handle or cable attached to the tip spindle.

Let Goltens Solve Your Challenge

Goltens is the right partner for ship owners and power plant operators all over the world. Response to all service enquiries typically falls within 12 hours.

Find Your Region’s Contact

Select a region below and find the right Goltens expert