Crankshaft Annealing and In-Situ Annealing

Saving operators millions on repairs and limiting asset downtime around the world

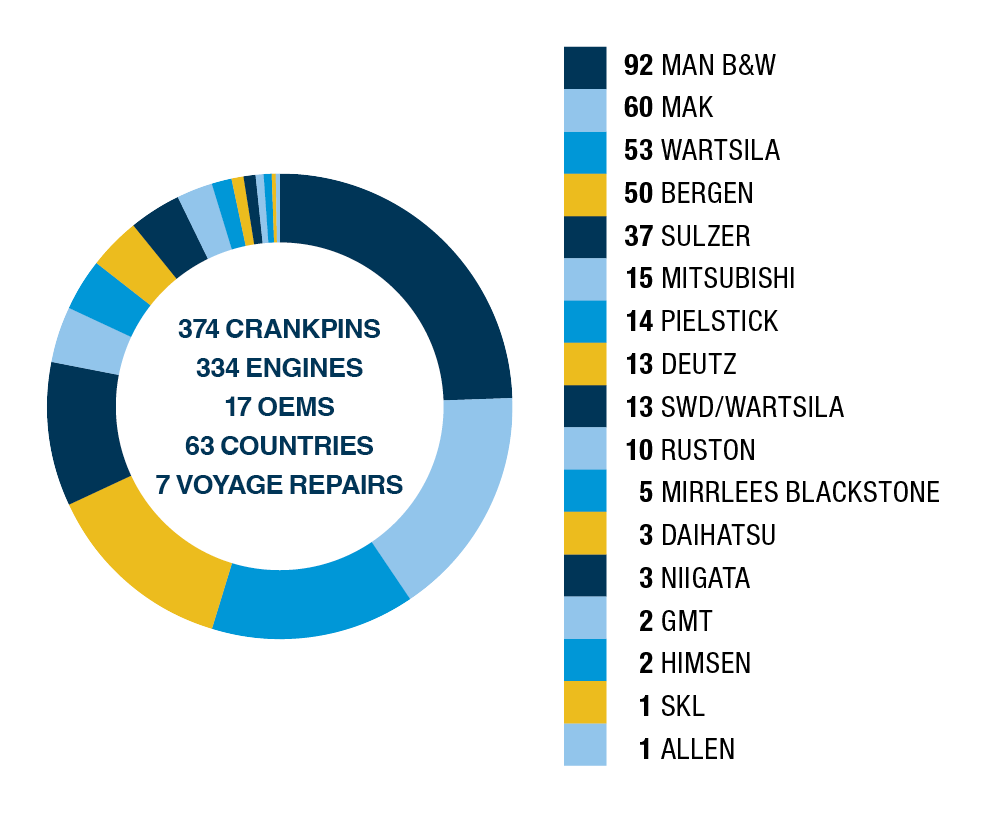

Crankshaft casualties often result in extremely high hardness levels in the crankpin, and that hardness has to be removed or the shaft will have to be condemned and replaced. Goltens has now successfully salvaged hundreds of crankshafts in over 60 countries across industries with its class approved and well proven in-place annealing process.

Historically the only option was to try and machine below the high crankshaft hardness, which very often resulted in a condemned shaft if the hardness extended below the rated diameter. Even if the machining was successful, a large amount of material generally needed to be removed from the shaft, limiting expected lifespan.

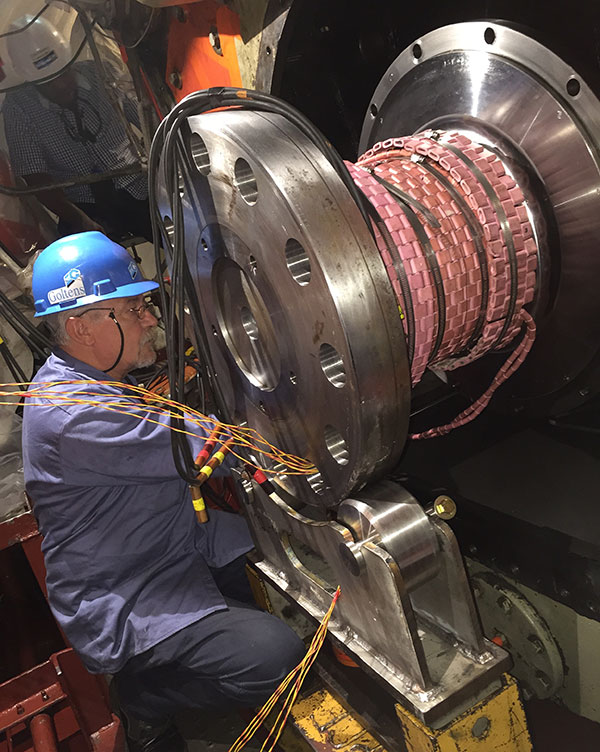

With in-situ annealing, the amount of material machined off the crankshaft is generally much less substantial, leaving significantly more material on the journal, which extends the life expectancy of the shaft. Goltens’ process for annealing crankshafts and other shafting can be done successfully In-Situ (with the crankshaft in-place) as well as in our workshops around the world. A deep understanding of the metallurgy, expansion characteristics and safety precautions has been developed and refined over the years into a safe, repeatable, highly controlled process.

At the end of the day, it’s really about two separate but related costs; the cost of the repair path chosen, and the cost of avoidable downtime for the engine. Annealing minimizes both, limiting the out-of-pocket repair expense, and restoring the engine in a matter of weeks as opposed to what can often turn out to be months.

With the annealing repair process so well-proven, pursuing a pure machining repair is akin to throwing away money.

Goltens’ Crankshaft Annealing Advantages

- Germanischer Lloyd Class approved annealing process

- Comprehensive capability to handle all aspects of hardness treatment inclusive of engine preparation, Inspection, pre-machining, hardness removal and finish machining as well as engine reassembly

- A large, global team of highly skilled In-Situ technicians to ensure a rapid, expert response anytime and anywhere

- Deep experience successfully annealing crankshafts across a broad array of makes and models of engines and rotating machinery

- Globally deployed and available portable annealing equipment for In-Situ application

Problems Most Often Observed/Addressed with Crankshaft and Journal Annealing

- Bearing Failure / Bearing Meltdown resulting in areas in the journal surface with excessive hardness values

What Is Crankshaft Annealing?

Annealing is a heat treatment process commonly used to remove the stress and hardness within a metal and to increase its ductility. Hardness is a measure of how resistant solid matter is to permanent shape change under application of force, and ductility is a material’s ability to deform under stress.

On a molecular level, when a metal such as steel cools down rapidly, the crystalline grains in the metal transform into a lenticular shape. This causes the metal to become harder but also more brittle in the process. Heating the metal to an appropriate temperature causes a homogenous growth of new crystals. The more heat is applied to the metal, the more its ductility increases and its hardness decreases. During annealing, the steel is heated above its critical temperature and held at this temperature for a period of time before controlled cooling. The controlled cooling process allows the crystals to diffuse into a more flexible, cubic-shaped state.

Factory Tempered State

Unhardened crankshafts generally have a hardness in the range of 250-350HB (Hardness Brinell).

Metal Characteristics

Homogenous grain structure with a hardness that provides desired strength, rigidity, resistance to wear, corrosion and impact.

Crankshaft Casualties

During a bearing failure, a crankshaft absorbs an incredible amount of heat. Emergency stopping of the engine introduces an uncontrolled cooling or quenching that often results in areas of excessive crankshaft hardness in the range of 600 to 700+HB

Metal Characteristics

Uneven grain structure with significant and visible differences in hardness create areas that are highly susceptible to cracking and potential shearing under force. Oftentimes, this hardness goes deep into the metal and without annealing would result in the condemnation of the crankshaft.

Annealing The Shaft

Heat is applied to the shaft in a tightly controlled manner above its critical temperature but well below the austenite range where the crankshaft could be permanently damaged. This temperature is held for a time period related to shaft diameter and extent of damage before being cooled in an equally controlled manner.

Metal Characteristics

During annealing, once the metal reaches the critical temperature, the molecules are allowed to recrystallize (realign) to a state consistent with its original ductility and hardness when it was delivered from the factory. Hardness levels are reduced to within acceptable parameters and within maker tolerances.

Post Annealing

Once the shaft is cooled, the surface of the journal is rough with scale from oxidation of the metal during the annealing process. The shaft must then be machined to finish diameter and machine polished to the required finish.

Metal Characteristics

The journal now has an acceptable hardness across the entire surface of the pin and the surface has been polished to a finish generally of 0.03Rα or better.

Let Goltens Solve Your Challenge

Goltens is the right partner for ship owners and power plant operators all over the world. Response to all service enquiries typically falls within 12 hours.

Find Your Region’s Contact

Select a region below and find the right Goltens expert