Sulphur Emissions Compliance

Choosing the right Sulphur Emissions compliance solution can be hard. Choosing the right retrofit partner is not.

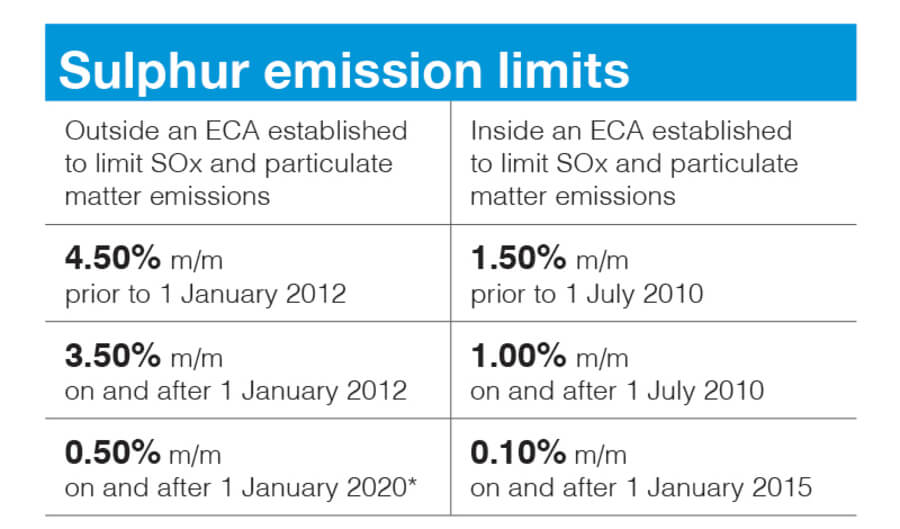

With the IMO 2020 in full effect, shipowners around the globe remain faced with a difficult choice. The time for hoping the enforcement of emissions regulations would be further delayed has passed and owners are now forced to decide on how they will comply going forward. Will you continue to operate your vessels using emissions compliant fuels or make the investment to ensure that emissions are cleaned using an exhaust gas scrubber?

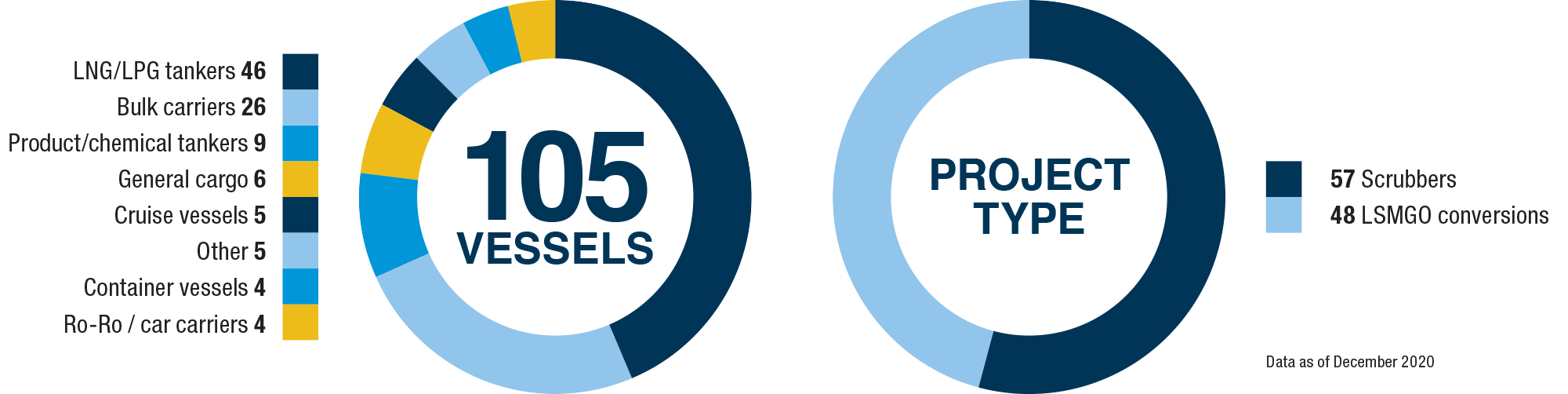

With almost 1,000 ballast water, scrubber and LSGO compliance retrofit projects completed or underway, Goltens is a clear leader in the retrofit space and a trusted partner to many respected ship owners around the world. Application of our well proven process leveraging our global network in 14 countries, ensures a predictably excellent result. Not only will your project be successful but our process is focused on limiting the costs and operational impacts owners face. Trust Goltens Green Technologies to help you navigate your chosen compliance path.

Let Goltens Solve Your Challenge

Goltens is the right partner for ship owners and power plant operators all over the world. Response to all service enquiries typically falls within 12 hours.

Find Your Region’s Contact

Select a region below and find the right Goltens expert