2-Stroke Engine Components Reconditioning

REDUCE, REUSE, RECONDITION – GOLTENS HELPS SUPPORT WAR ON WASTE BY EXTENDING 2-STROKE ENGINE COMPONENT LIFE CYCLES

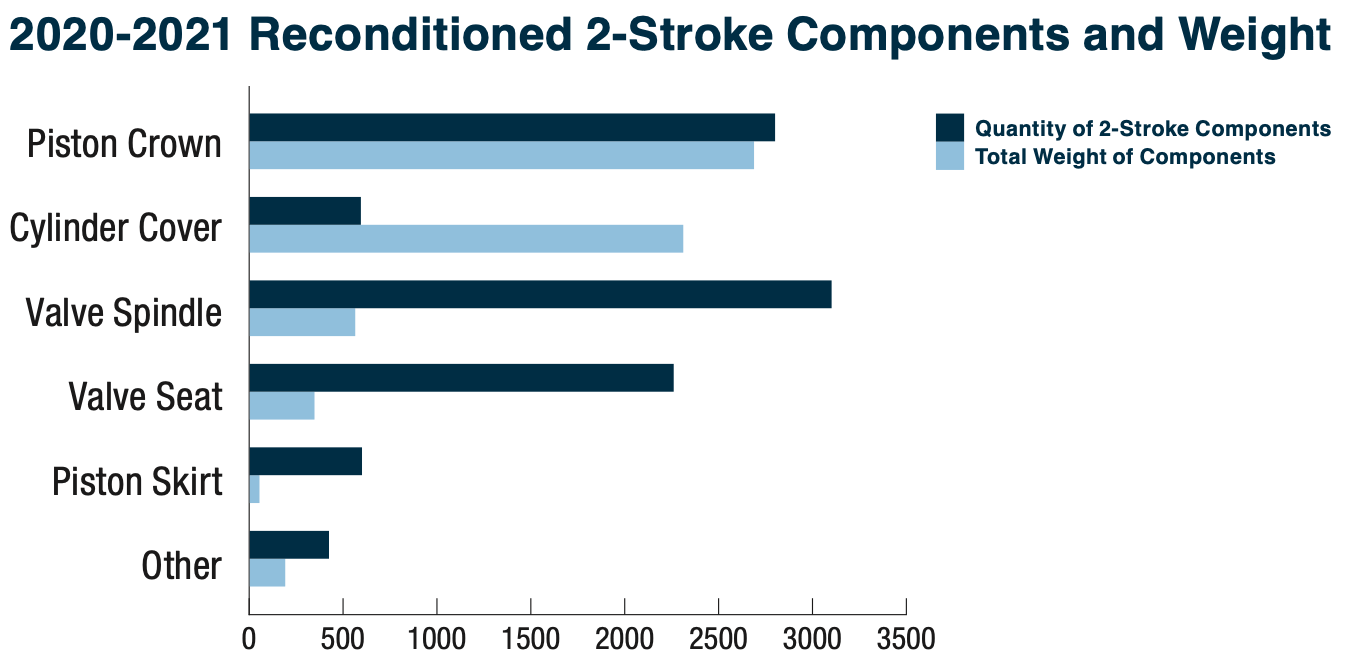

Each year Goltens’ stations recondition an average of around 5,000 critical 2-stroke engine components weighing over three million kilograms, dramatically reducing the environmental impact of engine operations by extending component life cycles.

As the world’s economies and major maritime and power corporations look for ways to limit the negative impacts of their operations on the global environment, the long-proven process of reconditioning core engine components is being looked at from a fresh angle. Reconditioning of piston crowns, connecting rods, exhaust valves and other major 2-stroke engine components has traditionally been viewed as an economical approach to engine operation and maintenance, but with the increasing focus on reducing carbon footprints, the environmental benefits of reusing components as opposed to consuming new ones are clear.

SUBSTANTIAL ANNUAL VOLUMES – 5,000 COMPONENTS/3,000 TONNES PER YEAR

Goltens is a preferred 2-stroke reconditioning service provider for some of the world’s largest operators and reconditions an average of 1,400 two-stroke pistons, 1,550 exhaust valve spindles, 1,130 valve seats, 300 piston skirts and 300 cylinder covers per year along with hundreds of other components. Assigning an average weight to each of these components, Goltens’ work results in an estimated reuse of over three million kilograms/three thousand tonnes per year of steel that is not sent to scrap and does not need to be mined and processed to make new components.

DEMONSTRATED QUALITY

Over our 80-plus years of service to the market, Goltens has reconditioned countless components for the maritime and power industries. Adherence to tight, ISO-controlled, and marine Class-certified processes has resulted in a near zero defect rate and the confident expectation of our customers of a second (or third) full life cycle for the component. Every component delivered by Goltens follows the exacting standards of the OEM without unnecessary consumption of raw materials associated with a new component.

COMPETITIVE COST

In general, reconditioning has been viewed as economical by the market when the price to recondition the piece is 50% or less than the price of new one. Substantial investments in CNC tooling, supply chain management, process reengineering and quality controls have enabled Goltens to continue to offer this invaluable service at competitive rates that meet this price sensitive criteria and limit the impacts of large-bore diesel engines on the environment.

Let Goltens Solve Your Challenge

Goltens is the right partner for ship owners and power plant operators all over the world. Response to all service enquiries typically falls within 12 hours.

Find Your Region’s Contact

Select a region below and find the right Goltens expert