On-Site Machining

Goltens’ On-Site machining capability eliminates the logistical and cost related issues that go along with repairs and major replacements on any large equipment that is not easily moved.

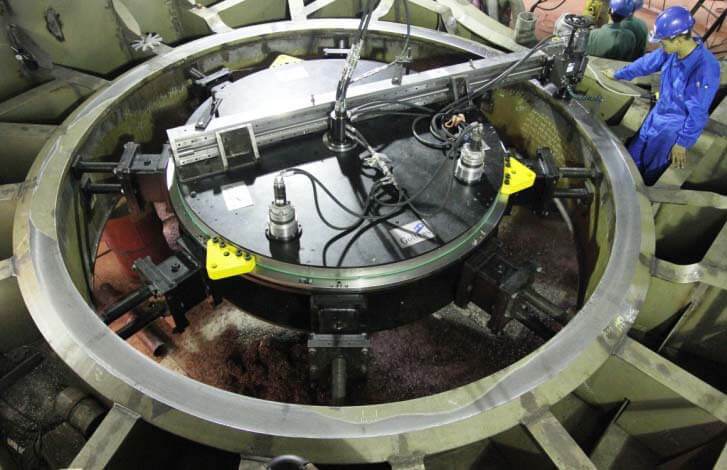

Beyond in-place journal machining and line boring applications, Goltens’ expert on-site machinists perform a broad spectrum of machining procedures including large scale flange facing, surface machining as well as addressing unique, one of a kind requirements with custom built tools.

Goltens’ culture as a precision tool maker and its constant investment in capital machinery and personnel related to on-site machining has made its stations around the globe capable of handling almost any specialized machining job. If we don’t have the proper tool for your special, one of a kind requirements, chances are we can build it.

Services commonly provided by Goltens’ teams include:

- Small and large-scale flange facing up to 6 meter diameter

- Surface/XYZ milling

- Reaming

- Sheared / Broken Stud removal

- Metal stitching of cast components (i.e. Engine block repairs after con rod failure, crack in cooling space and casings etc.)

Our experience covers a full spectrum of marine/shipyard, Offshore, Oil & Gas, Stationary Power and general industrial applications worldwide.

Goltens’ On-Site Machining Advantages

- A large global team of Machining Specialists to ensure a rapid, expert response anytime and anywhere

- Wide range of portable, precision tooling of small and large scale deployed at stations around the globe

- Specialized laser guided measuring/alignment equipment

- Decades of success and experience

Common Applications

- Leaking Mating Surfaces

- Out of Line Mating Surfaces

- Worn out / Damaged Landing Surfaces

- Corroded Guide Rails / Foundations

- Seized/sheared bolts

- Cracked/broken metal components

- Engine block repairs

Case Studies

In-Place Machining Solution Resolve Shafting Issue

Case StudyGoltens removes 36 metric tons of steel on-site with self-leveling radial milling machine

Case StudyX-Y vertical milling and line boring

Case StudyDeck reel hub flange facing for offshore pipelay vessel – Vietnam

Let Goltens Solve Your Challenge

Goltens is the right partner for ship owners and power plant operators all over the world. Response to all service enquiries typically falls within 12 hours.

Find Your Region’s Contact

Select a region below and find the right Goltens expert