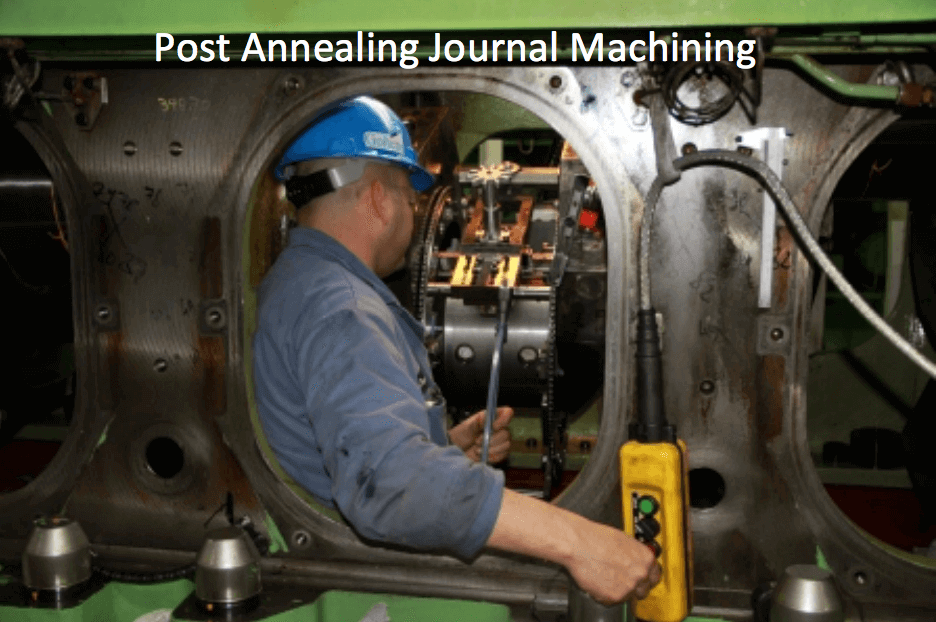

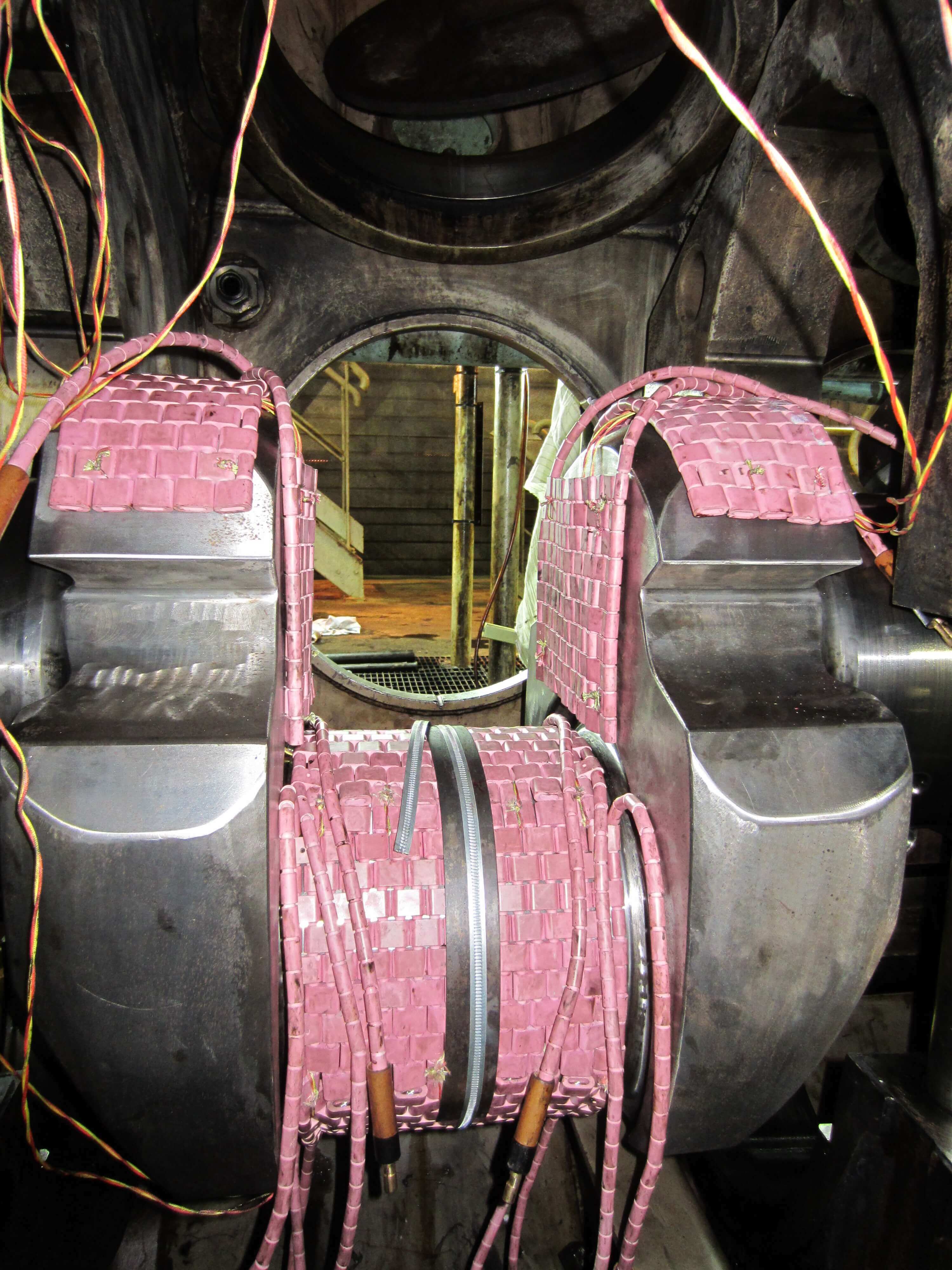

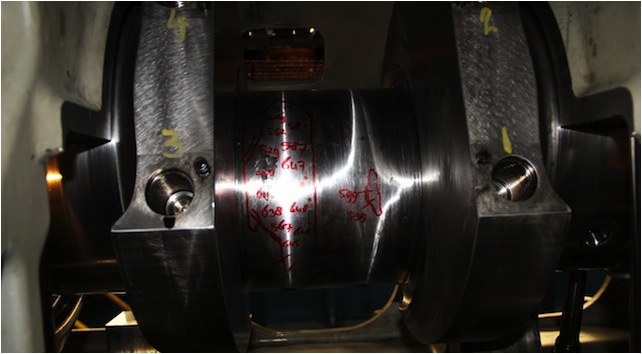

Annealing And Machining Salvages Another Badly Damaged Crankshaft

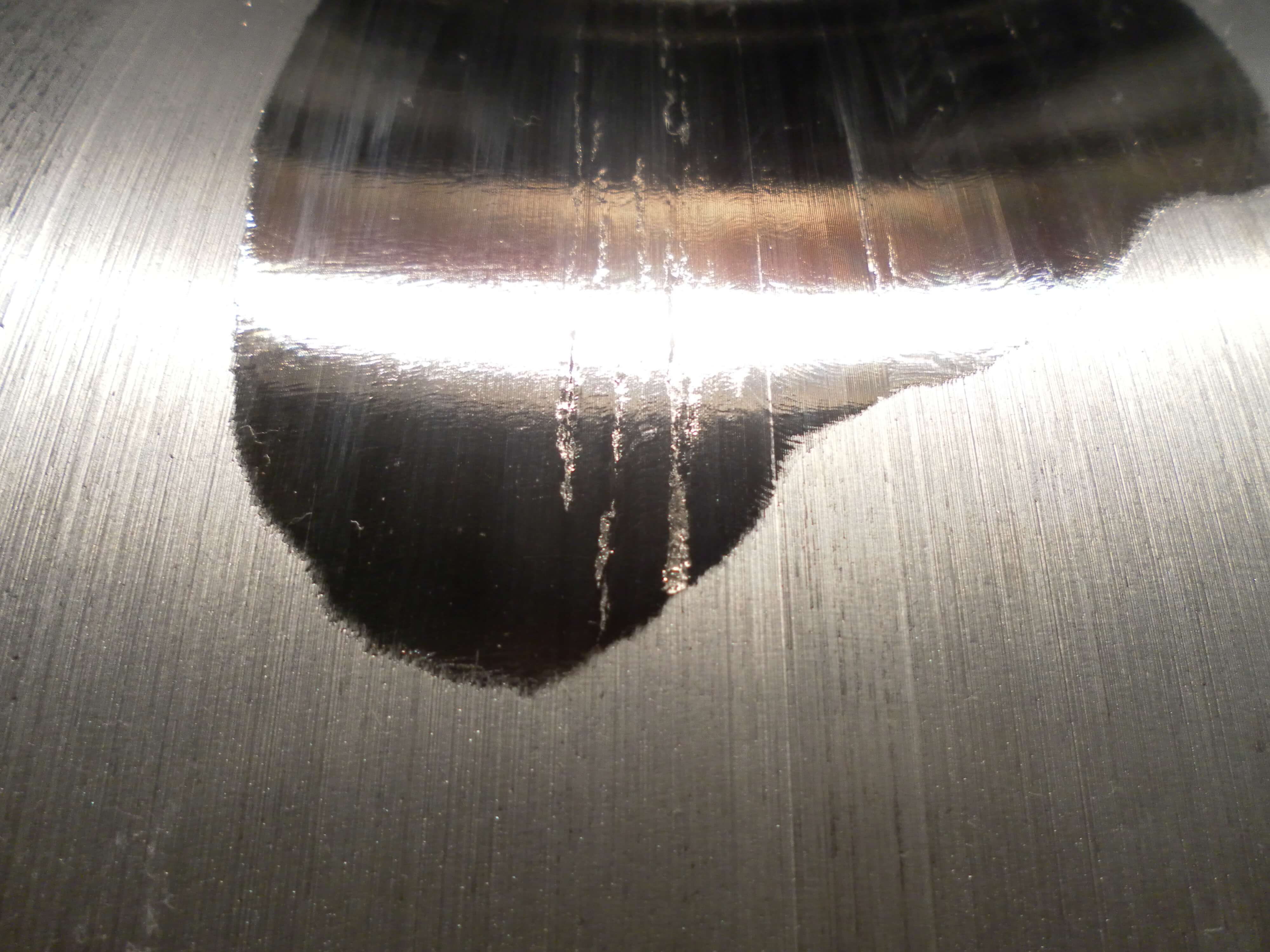

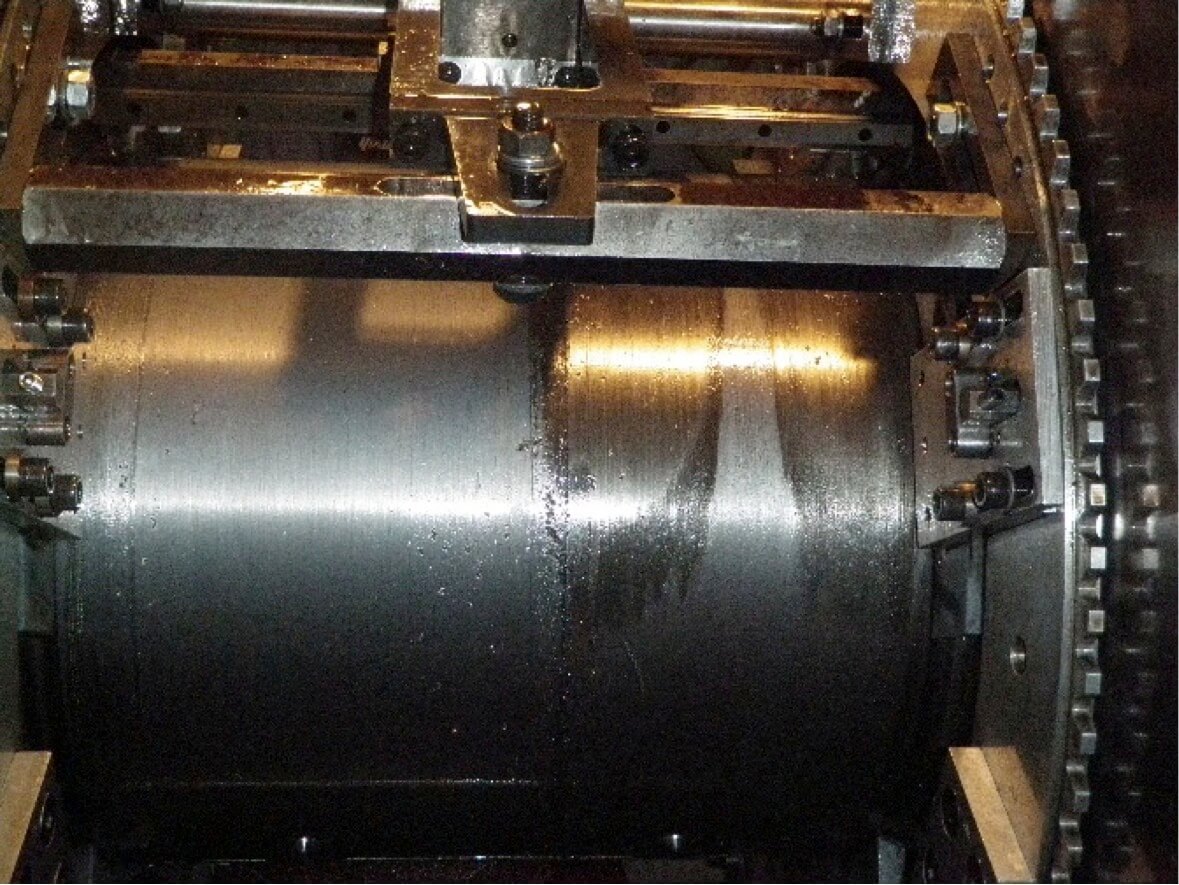

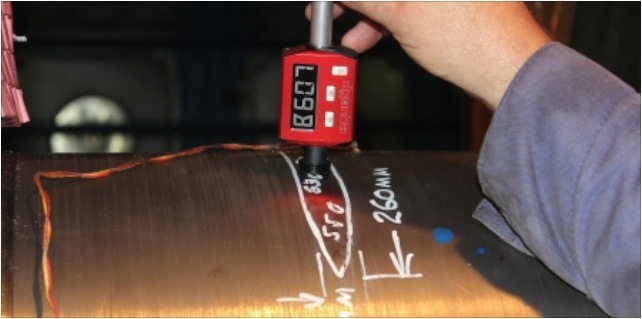

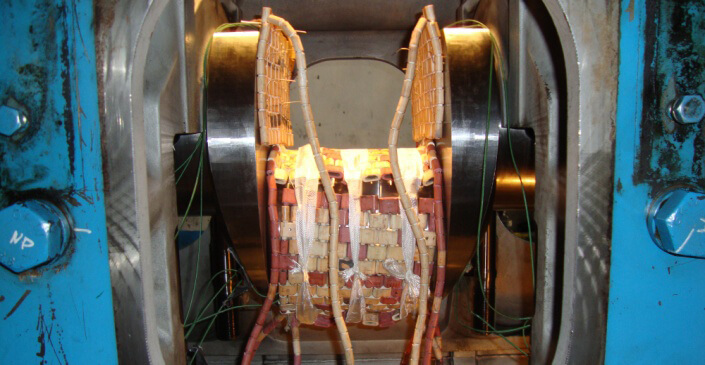

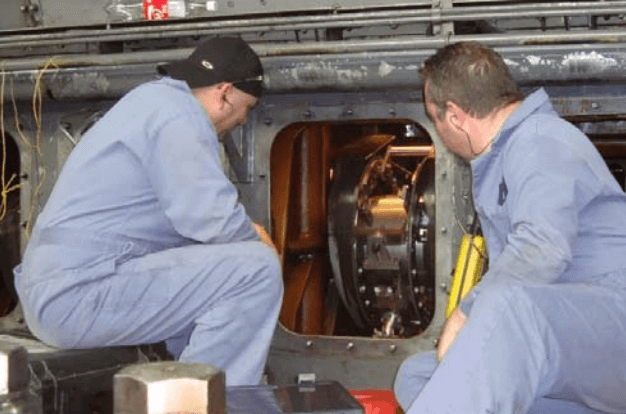

Goltens was contacted by a containership operator to inspect damage on its MAN 9L 48/60 main engine crankshaft. During operation, the main engine’s connecting rod bolts gave away and caused major damage to crankpin number 4. Goltens boarded the vessel at Dubai Maritime City for inspection.

Learn More Download Now